An online peel strength detection device and working method of a hook cutting machine for hook and loop fasteners

A peel strength and detection device technology, which is applied in the direction of measuring devices, machine/structural component testing, instruments, etc., can solve problems such as uncontrollable quality problems, low work efficiency, time-consuming and labor-intensive problems, and achieve the elimination of manual detection , Improve work efficiency and stabilize product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

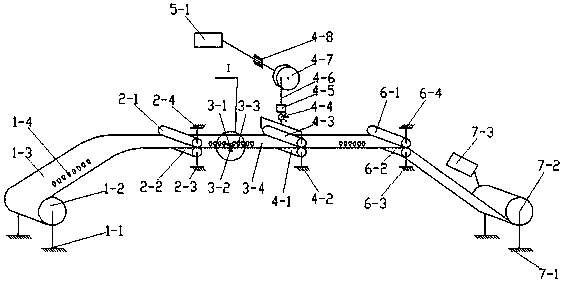

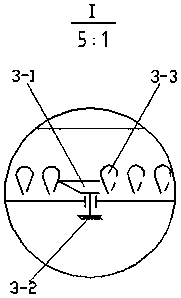

[0024] Refer to attached figure 1 , driven by the rewinding motor 7-3, the rewinding reel 7-2 rotates, and the Velcro tape 1-3 to be cut is output from the unwinding reel 1-2, and is pressed by the unwinding roller system 2 After the roller 2-1 and the lower pressure roller 2-2 control the positioning, the hook cutting knife (similar to the haircut tool scissors) 3-1 of the hook cutting system 3 cuts the hook, and then enters the detection system 4 to test the peel strength, and then Through the upper pressure roller 6-1 of the winding traction system 6, the mutual cooperation of the lower pressure roller 6-2 controls the positioning, and finally the hook-cut Velcro tape is wound on the winding drum 7-2.

[0025] When the detection system 4 is working, the crank slider mechanism 4-7, driven by the power source, converts the rotary motion into a reciprocating linear motion, so that the soft lifting rope 4-6 of the detection pressure roller performs a linear reciprocating motion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com