Hydrodynamic force conversion device

A conversion device, fluid power technology, applied in the direction of machine/engine, rotary piston engine, rotary or oscillating piston engine, etc., can solve the problems of low energy conversion efficiency, complex structure of gas turbine or water turbine, etc., to achieve simple structure, low cost Low, easy-to-manufacture effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

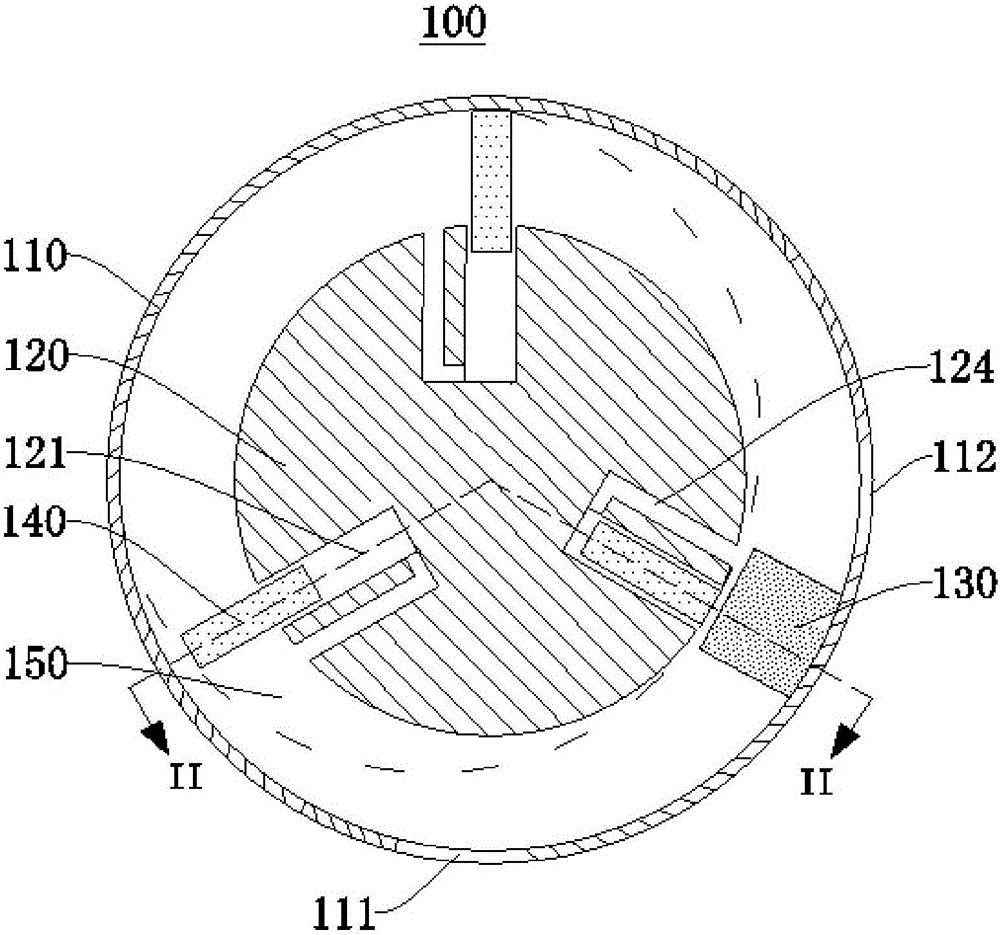

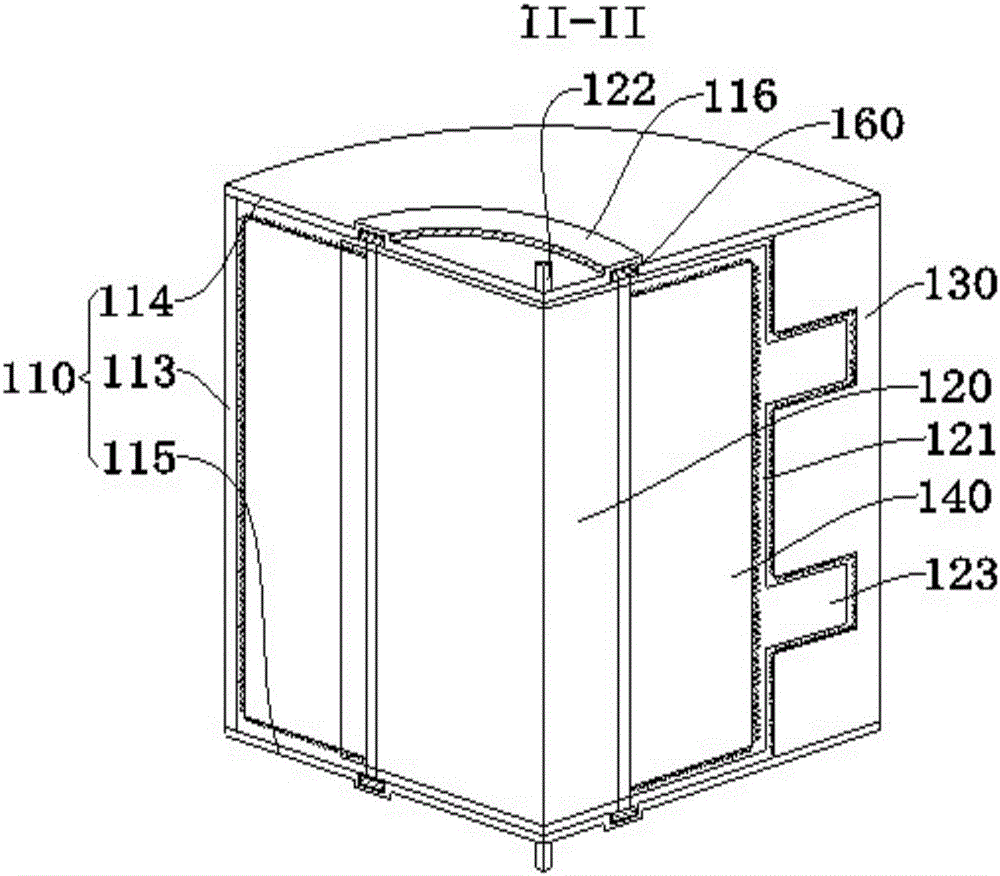

[0034] figure 1 For the schematic structural diagram of the fluid power conversion device provided in this embodiment, please refer to figure 1 .

[0035] This embodiment provides a fluid power conversion device 100 . The fluid power conversion device 100 has an outer stator inner rotor structure. The fluid power conversion device 100 includes a stator 110 , a rotor 120 , a barrier plate 130 and a slider 140 . The stator 110 has a cylindrical shape. The rotor 120 is cylindrical.

[0036] The rotor 120 is rotatably provided inside the stator 110 . An annular cavity 150 is formed between the opposite side walls of the rotor 120 and the stator 110 . The cross-sectional shape of the annular cavity 150 is a regular annular shape. An inlet 111 and an outlet 112 are opened on the stator 110 . The blocking plate 130 is fixedly connected to the stator 110 and is slidably connected to the rotor 120 . The barrier plate 130 is located in the annular cavity 150 and between the inl...

no. 2 example

[0053] This embodiment provides a fluid power conversion device 100 , which differs from the fluid power conversion device in the first embodiment in that the fluid power conversion device 100 provided in this embodiment has an outer rotor inner stator structure.

[0054] Figure 5 For the schematic structural diagram of the fluid power conversion device provided in this embodiment, please refer to Figure 5 .

[0055] The stator 110 is cylindrical. An inlet 111 and an outlet 112 are opened on the stator 110 . The rotor 120 has a cylindrical shape. The rotor 120 is rotatably sleeved on the periphery of the stator 110 . An annular cavity 150 is formed between the rotor 120 and the stator 110 . Both the inlet 111 and the outlet 112 communicate the annular cavity 150 with the outside. The blocking plate 130 is fixedly connected to the stator 110 and is slidably connected to the rotor 120 . The barrier plate 130 is located in the annular cavity 150 and between the inlet 111...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com