A multifunctional oil rod scraping and wax removal device

A multi-functional, oil-rod technology, used in drill pipes, cleaning appliances, drilling equipment, etc., can solve problems such as cumbersome operations, inability to fully meet on-site construction, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

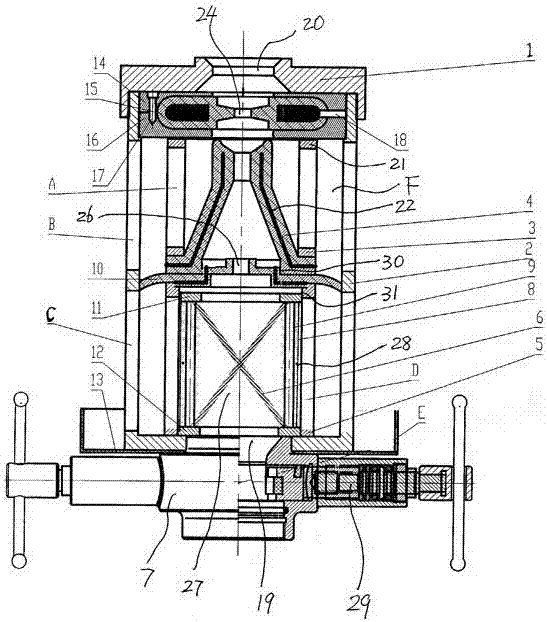

[0029] The axial section structure and operating principle of the multifunctional oil rod scraping and wax removal device provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

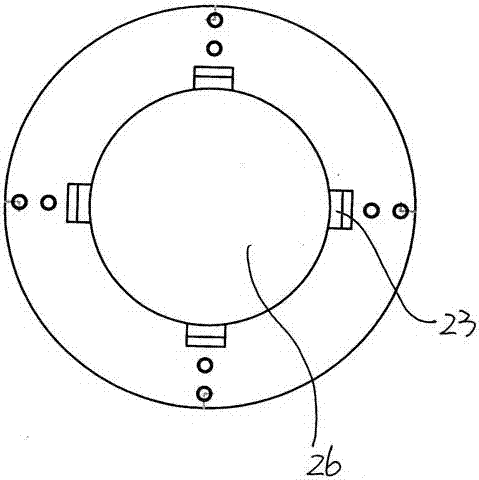

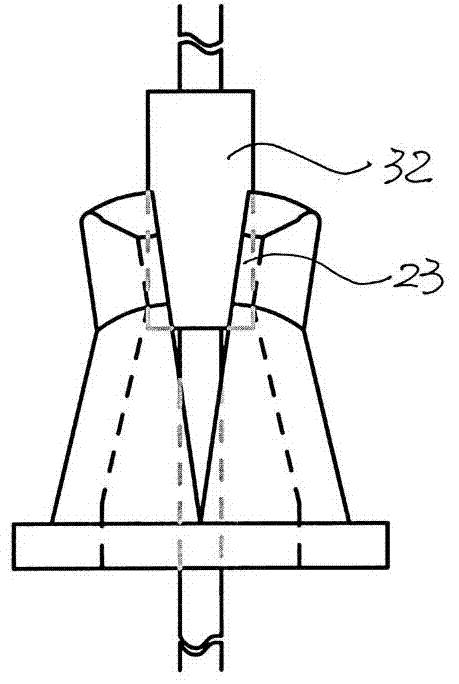

[0030] Such as figure 1 Shown is a schematic diagram of the best structure of the multifunctional oil rod scraping and wax removal device provided by the present invention. The structure of the multifunctional oil rod scraping and waxing device includes

[0031] The well sealing blowout prevention box mechanism 7 matching the wellhead of the oil well, the cylindrical casing 2 with the upper gland 1 and the sucker rod wax scraping and oil scraping mechanism assembly arranged in the cylindrical casing, and the cylindrical casing There is a certain sliding gap F in the horizontal direction between the body 2 and the sucker rod wax-scraping oil-scraping mechanism assembly; a number of oil-out wax grooves C are arranged on the wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com