Bidirectional TMD control device and parameter determination method

A control device, vertical technology, applied in the direction of building components, building structure, building type, etc., can solve the problem of not considering the damping of the superstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

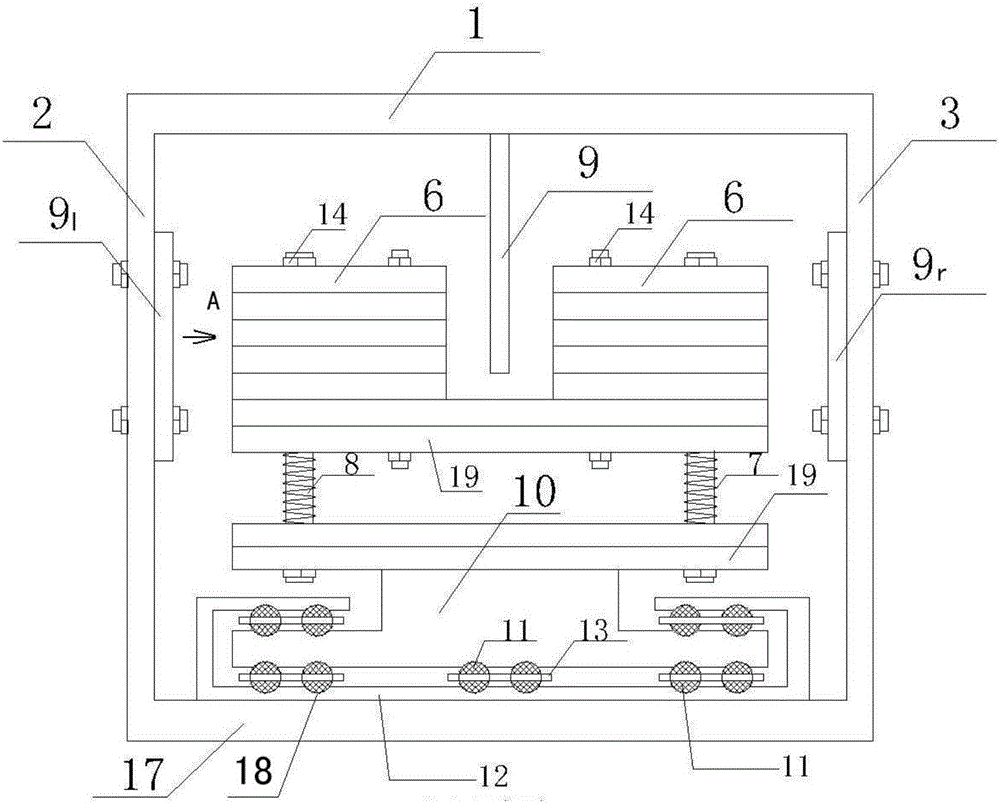

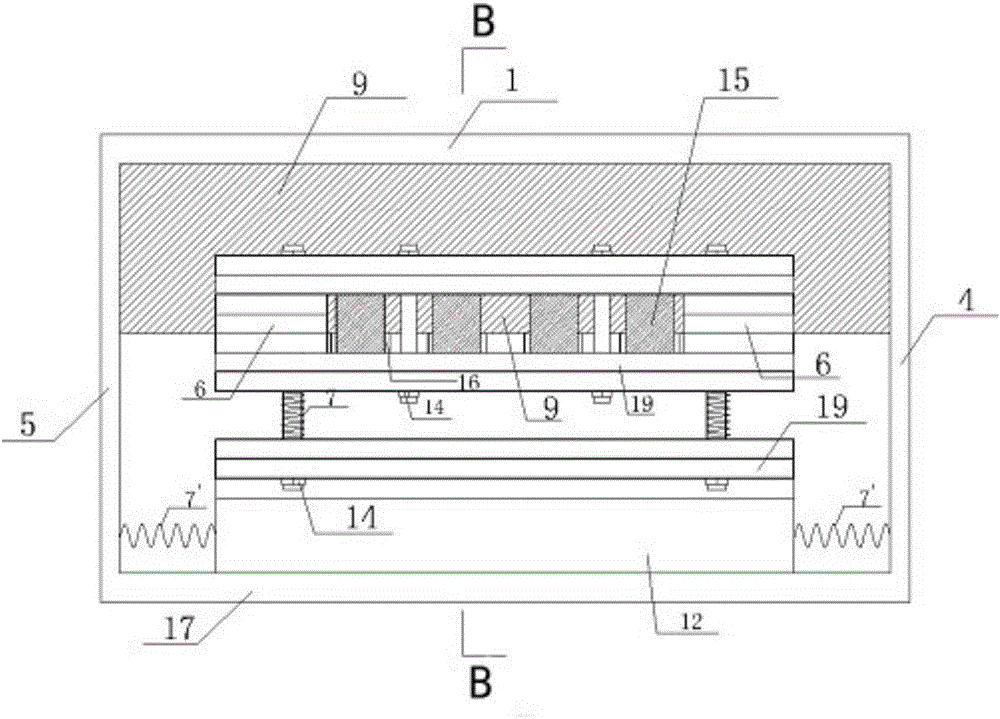

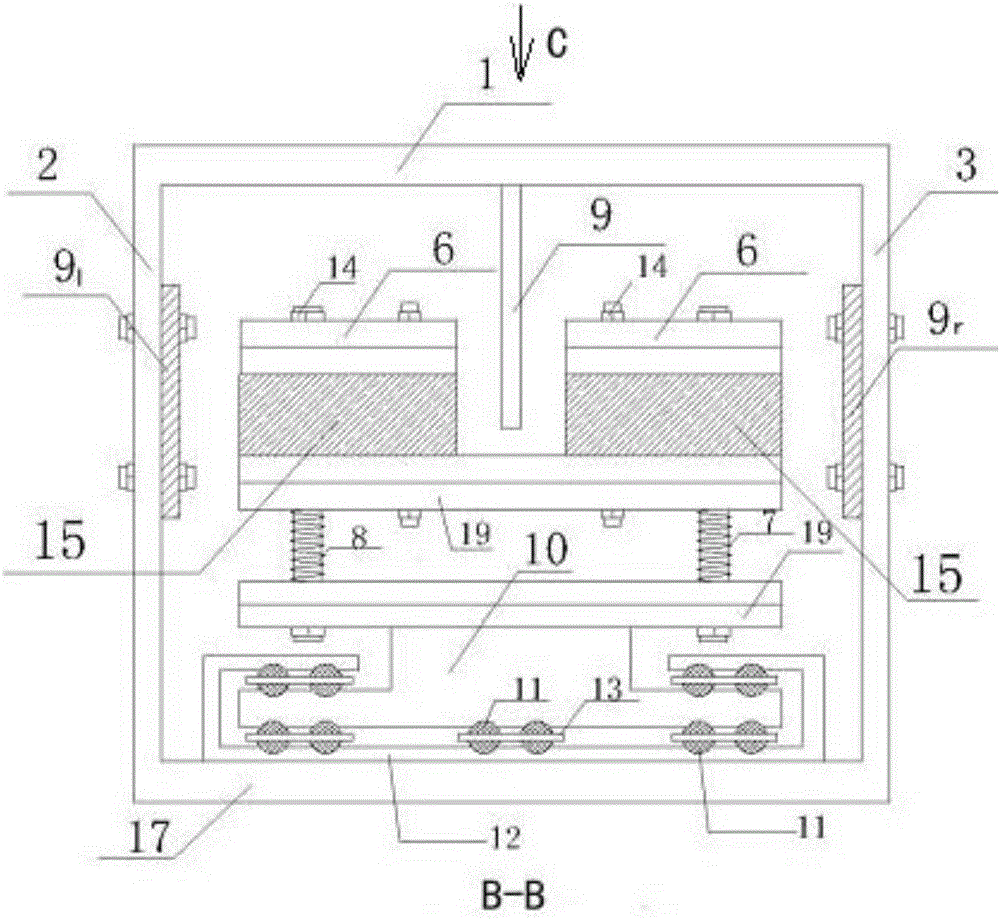

[0080] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 As shown, the two-way TMD control device has a base plate 17 placed horizontally, the second steel plate 2, the third steel plate 3, the fourth steel plate 4, and the fifth steel plate 5 are vertically installed on the base plate 17 respectively, and the first steel plate 1 is parallel to the base plate 17 , constituting a semi-sealed cube, the mass block 6 is installed on the sixth steel plate 19 through the guide rod 8, and the vertical spring 7 that can provide vertical stiffness and control the vertical movement of the TMD is nested on the guide rod 8, the first The six steel plates 19 are installed on the upper end of the T-shaped base 10, and the lower part of the base 10 is nested in the track groove 18 of the track assembly 12 through the steel ball 11 and the steel ball slot 13; the upper end of the copper plate 9 is installed on the first steel plate 1 At the middle position, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com