Quick-setting rubber spraying machine

A quick-setting rubber and spraying machine technology, which is applied in the direction of construction and building construction, can solve problems such as inability to guarantee construction quality, reduce spraying quality, and uneven film thickness, so as to improve spraying construction efficiency, improve spraying quality, The effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

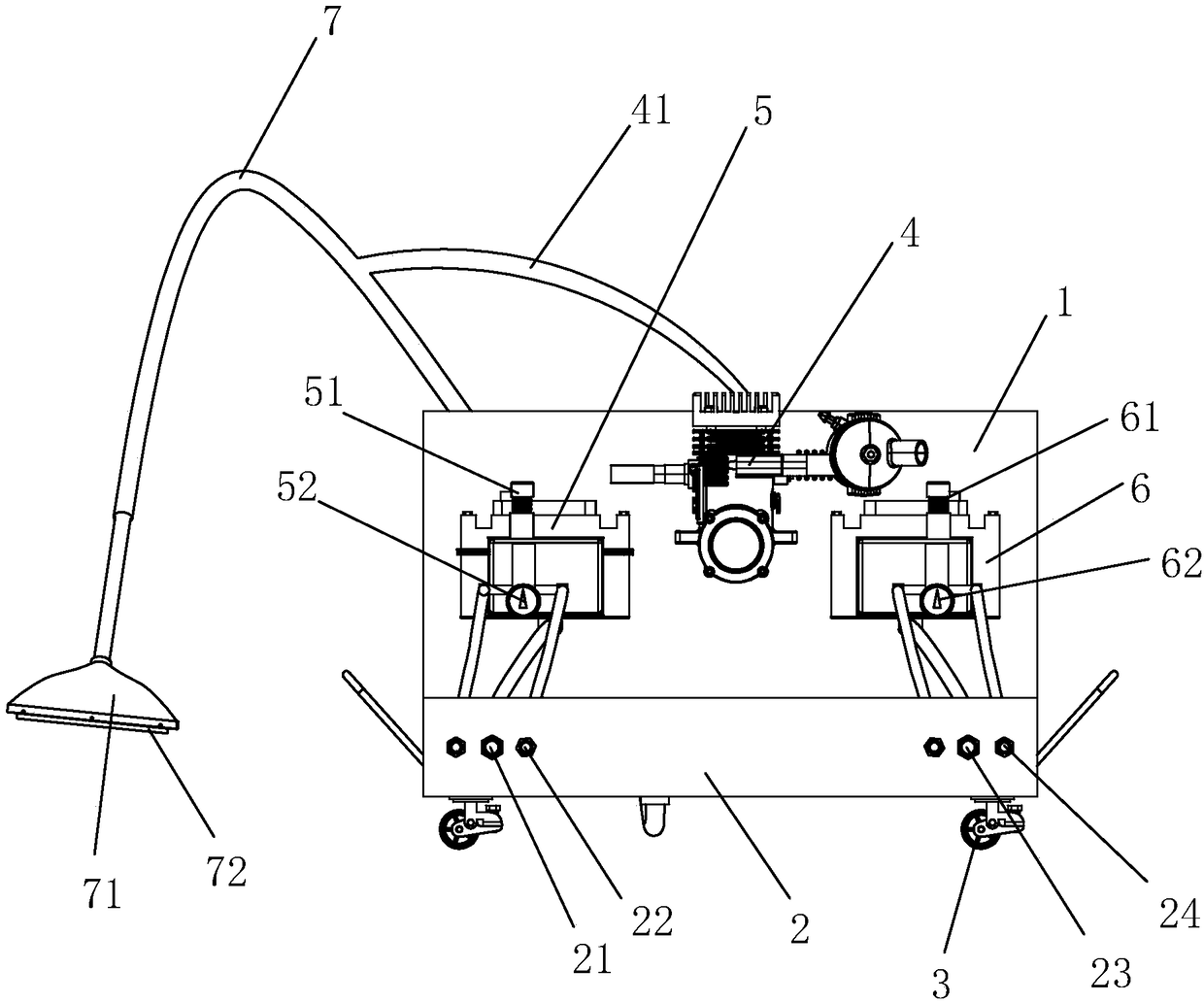

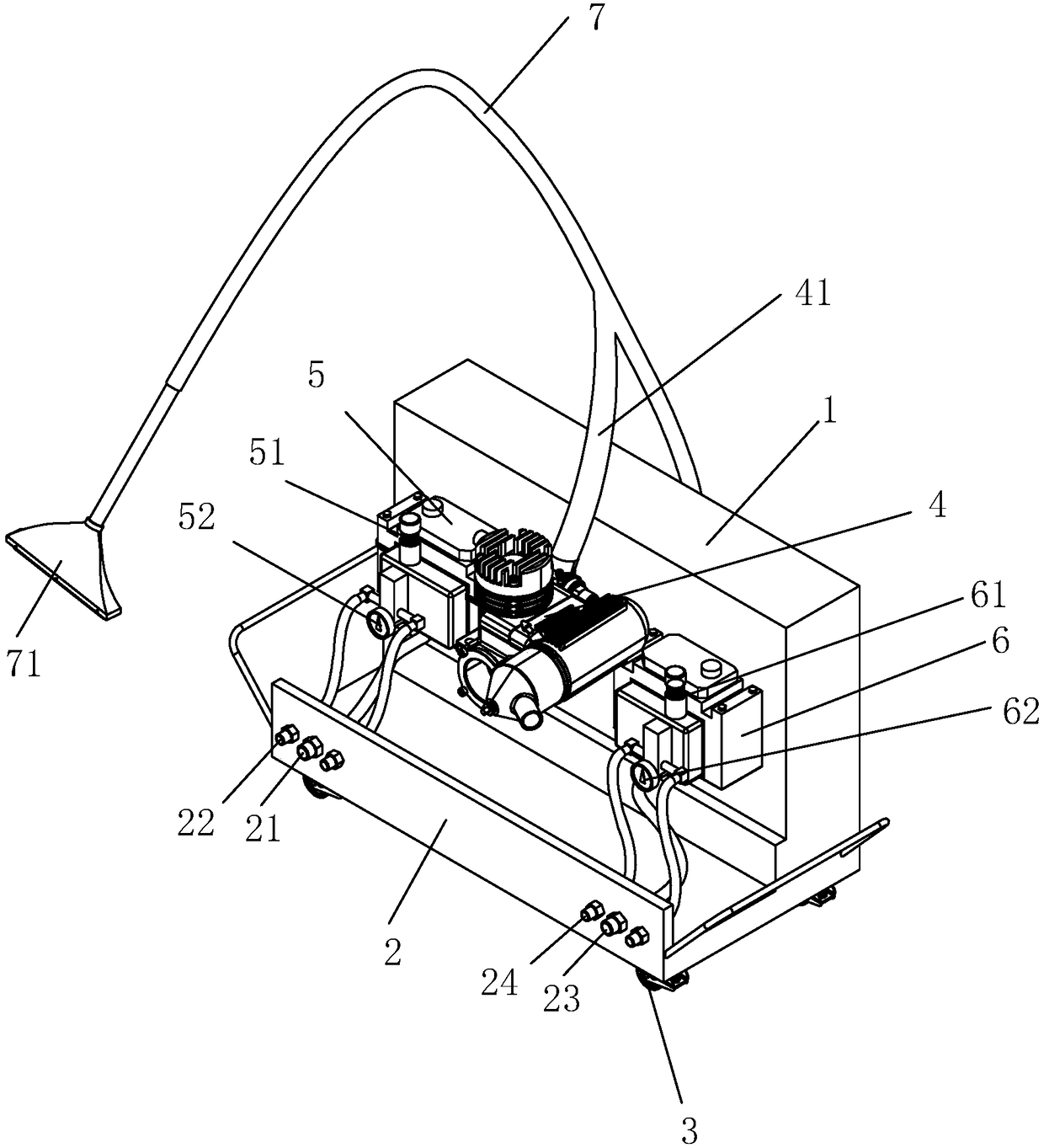

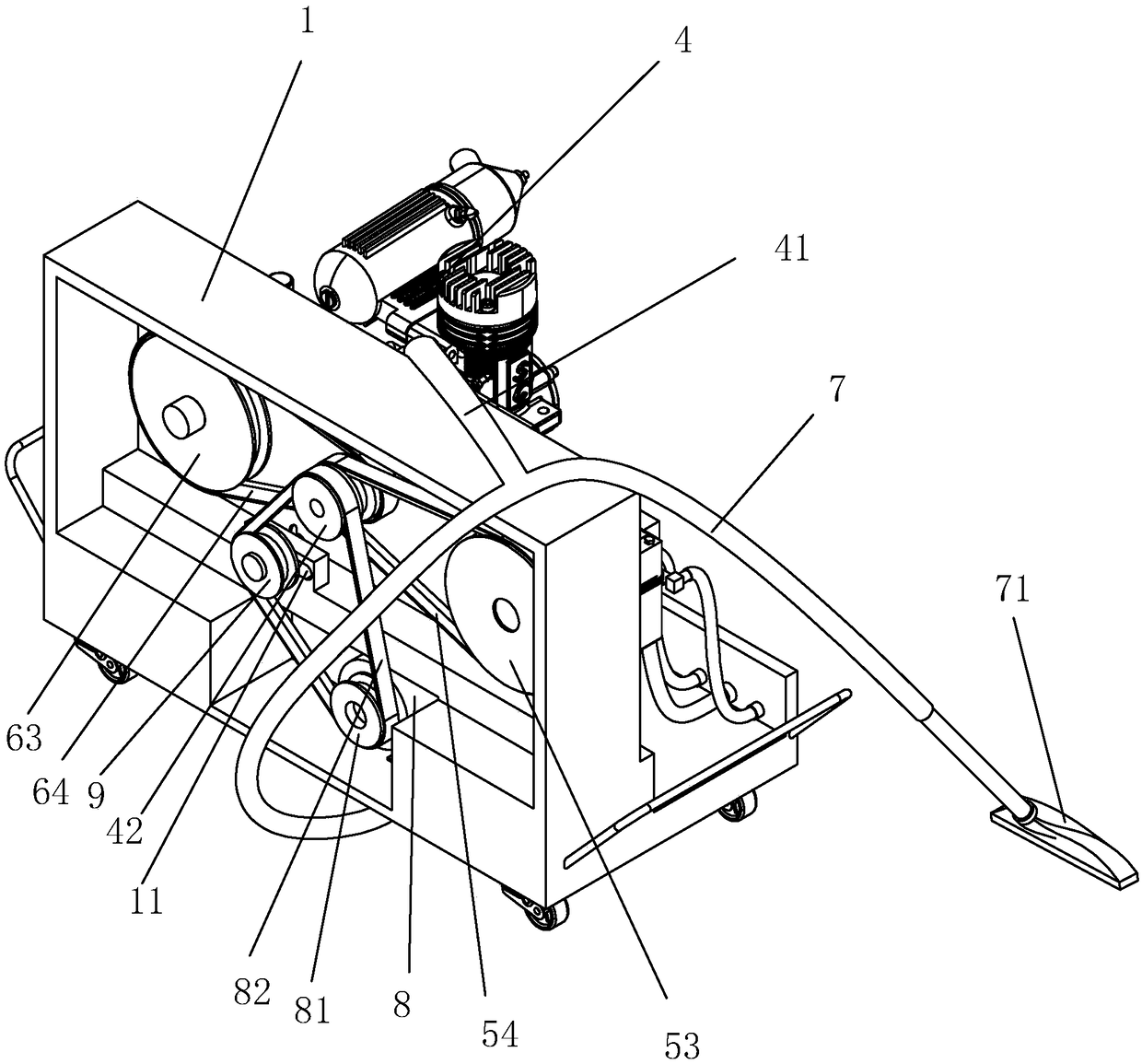

[0036] Embodiment: a quick-setting rubber spraying machine, comprising a frame 1, the front side of the frame 1 is provided with a front interface plate 2, and the front interface plate 2 is provided with a feed port-21, a discharge port-22, a feed port Port two 23 and discharge port two 24, the frame 1 lower end is provided with traveling wheel 3.

[0037] Gasoline engine 4, diaphragm pump 1 5 and diaphragm pump 2 6 are installed on frame 1, gasoline engine 4 is located in the middle of diaphragm pump 1 5 and diaphragm pump 2 6, diaphragm pump 1 5 is connected to pressure regulating valve 1 51, and pressure regulating valve 1 51 is connected to pressure gauge 1 52, diaphragm pump 1 5 is connected to feed port 1 21 through pipelines, pressure regulating valve 1 51 is connected to 2 outlets 1 22 through pipelines; diaphragm pump 2 6 is connected to pressure regulating valve 2 61, Pressure regulating valve 2 61 is connected to pressure gauge 2 62, diaphragm pump 2 6 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com