Mask plate and display panel production method

A mask and substrate technology, applied in the direction of ion implantation plating, coating, electrical components, etc., can solve local unevenness, seriousness, color mixing and other problems, and achieve the effect of reducing color mixing problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

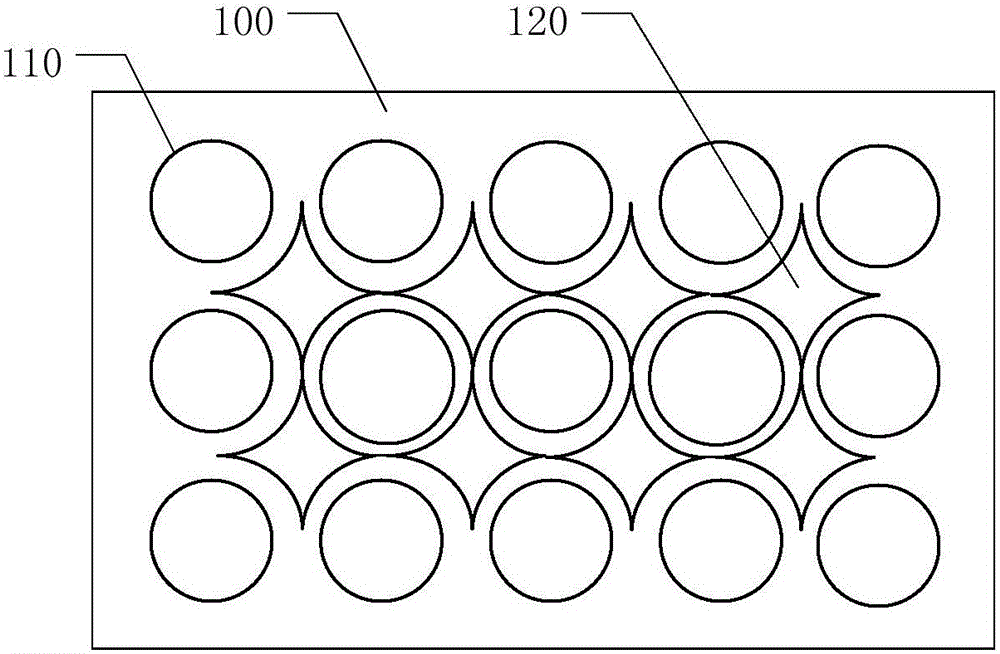

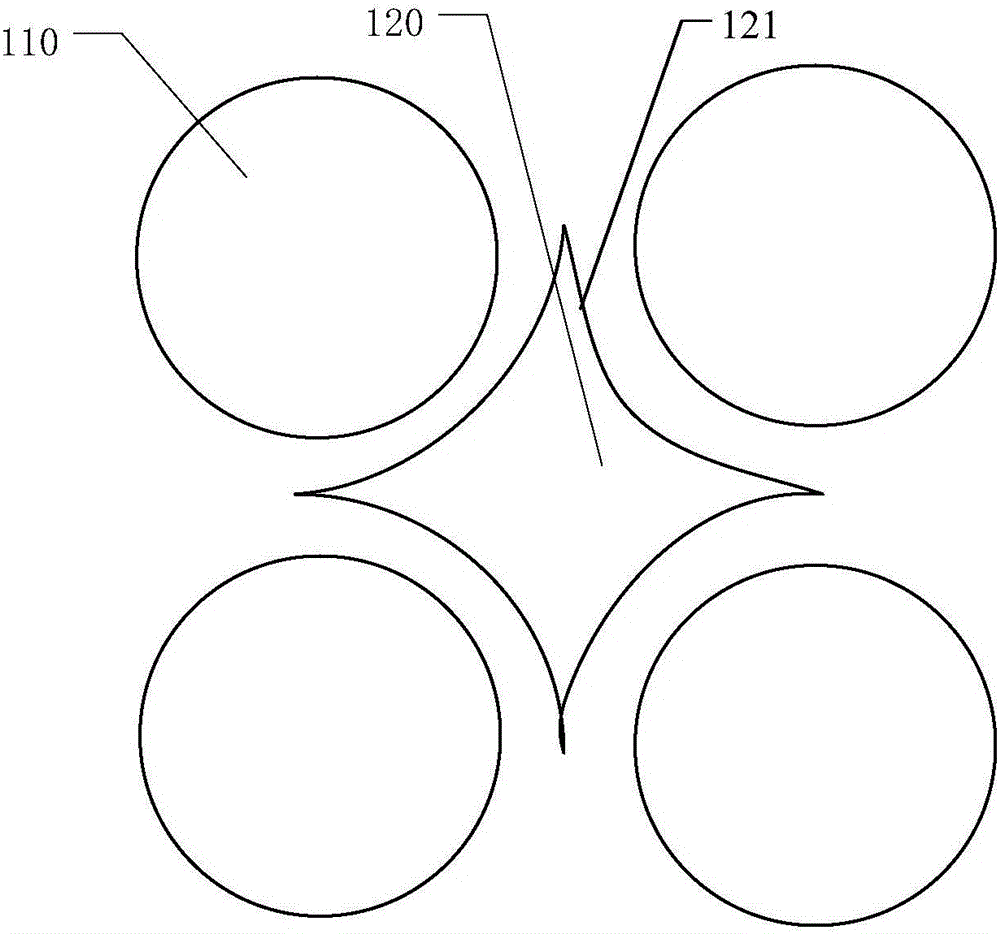

[0036] In order to avoid pixel color mixing, the present invention provides a mask plate used in the evaporation process of the display panel. Preferably, the mask is a metal mask. refer to figure 1 , which shows a schematic diagram of the mask plate of the present invention. The mask plate includes a body 100 having a plurality of openings 110 and a spacer. The opening 110 defines a thin film pattern, such as a pixel pattern. The opening 110 may be in the shape of a circle, a rectangle, a rhombus, a trapezoid or other irregular shapes, so that the pattern of the thin film evaporated using the mask is also a circle, a rectangle, a rhombus, a trapezoid or other irregular shapes. A plurality of openings 110 are arranged along the row direction and the column direction to form an array of openings to form a pixel array in the evaporation process of the display panel. The spacer is located between adjacent openings 110 . A plurality of spacers 120 are provided on the spacer. ...

no. 2 example

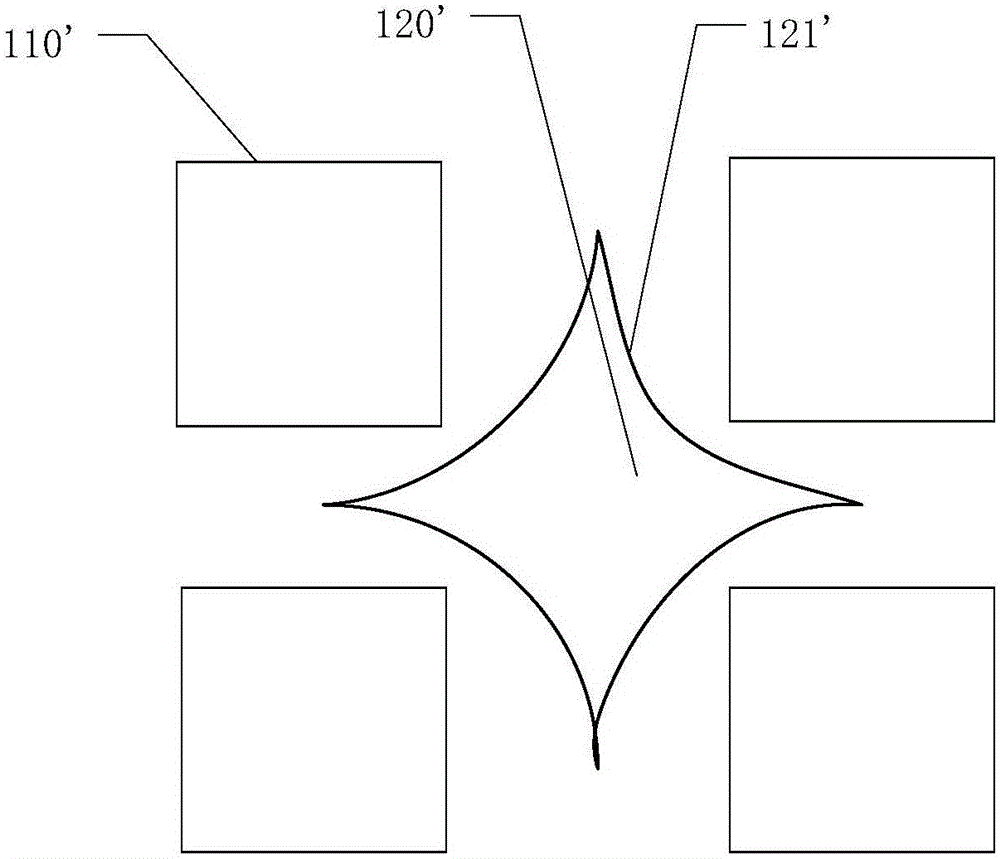

[0040] see Figure 2B ,and Figure 2A Similarly, each spacer 120' is located between four adjacent openings 110'. The edge of each spacer 120' facing the opening 110' adjacent thereto does not have a shape suitable for the opening 110'. For example, each opening 110' is rectangular, and the spacer 120' between the four rectangular openings 110' has four arc-shaped edges 121' respectively facing the four rectangular openings 110'. Preferably, each arc-shaped edge 121' has the same center as the rectangular opening 110' facing it.

no. 3 example

[0042] see Figure 2C ,and Figure 2B Similarly, each spacer 120" is located between four adjacent openings 110". The edge of each spacer 120" facing the opening 110" adjacent to it has a shape suitable for the opening 110". For example, each opening 110" is a rectangle, and the interval between four rectangular openings 110" The piece 120" has fold-line-shaped edges 122" respectively facing the four rectangular openings 110". Preferably, each zigzag edge 122" has two sides parallel to the length and width of the rectangular opening 110', respectively. Each zigzag edge 122" has the same center as the rectangular opening 110' facing it.

[0043] Specifically, the above Figure 2A The first embodiment shown, Figure 2B The second embodiment shown and Figure 2C In the third embodiment shown, the four spacers adjacent to an opening are engaged such that the opening is located within the closed area formed by the four spacers adjacent thereto.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com