A symmetrical laminated high-strength copper-clad laminate and its preparation method

A high-strength, copper-clad laminate technology, applied in chemical instruments and methods, other household appliances, electronic equipment, etc., can solve problems such as damaged equipment, reduced equipment service life, and production environment damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The embodiment of the present invention provides a method for preparing a symmetrically stacked high-strength copper clad laminate, which includes the following steps:

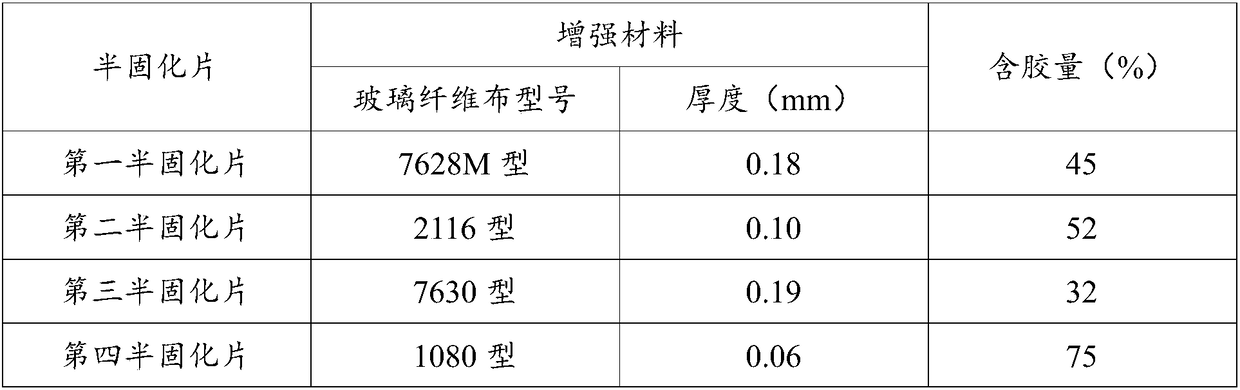

[0073] Choose copper foil and the first prepreg, second prepreg, third prepreg, and fourth prepreg as shown in Table 1;

[0074] Table 1 Reinforcing materials and glue content of each prepreg

[0075]

[0076] Laminate one copper foil, one first prepreg, one second prepreg, one third prepreg, four fourth prepregs, one third prepreg, one second prepreg, and one first prepreg in sequence, Then, they were put into a vacuum hot press for hot pressing to obtain copper clad laminate one respectively. The parameter settings of the vacuum hot press are shown in Table 2.

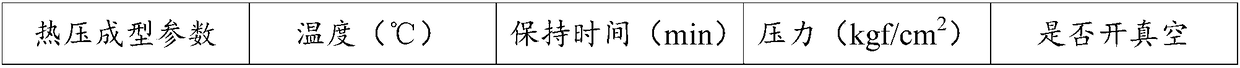

[0077] Table 2 Hot press molding parameter setting table

[0078] Hot press molding parameters

Embodiment 2

[0080] The embodiment of the present invention provides a method for preparing a symmetrically stacked high-strength copper clad laminate, which includes the following steps:

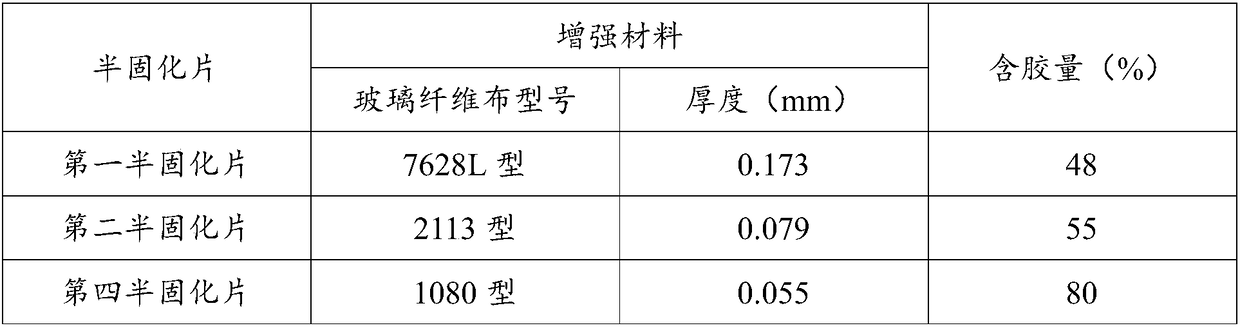

[0081] Choose copper foil and the first prepreg, second prepreg, third prepreg, and fourth prepreg as shown in Table 3;

[0082] Table 3 Reinforcing materials and glue content of each prepreg

[0083]

[0084] Laminate one copper foil, one first prepreg, one second prepreg, one first prepreg, four fourth prepregs, one first prepreg, one second prepreg, and one first prepreg in turn , And then put it into a vacuum hot press for hot pressing to obtain two copper clad laminates respectively. The parameter settings of the vacuum hot press are shown in Table 4.

[0085] Table 4 Hot press forming parameter setting table

[0086]

[0087]

Embodiment 3

[0089] The embodiment of the present invention provides a method for preparing a symmetrically stacked high-strength copper clad laminate, which includes the following steps:

[0090] Choose copper foil and the first prepreg, second prepreg, third prepreg, and fourth prepreg as shown in Table 3;

[0091] Table 5 Reinforcing materials and glue content of each prepreg

[0092]

[0093] Laminate one copper foil, one third prepreg, one second prepreg, one third prepreg, four fourth prepregs, one third prepreg, one second prepreg, and one third prepreg in turn , And then put it into a vacuum hot press for hot pressing to obtain three copper clad laminates. The parameter settings of the vacuum hot press are shown in Table 4.

[0094] Table 6 Hot press forming parameter setting table

[0095]

[0096]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com