Full-range packaging type printing head

A printing head and wrapping technology, applied in the field of construction, can solve the problems of less overall freedom, poor versatility, inconvenient transportation and movement, etc., and achieve the effect of improving the working range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

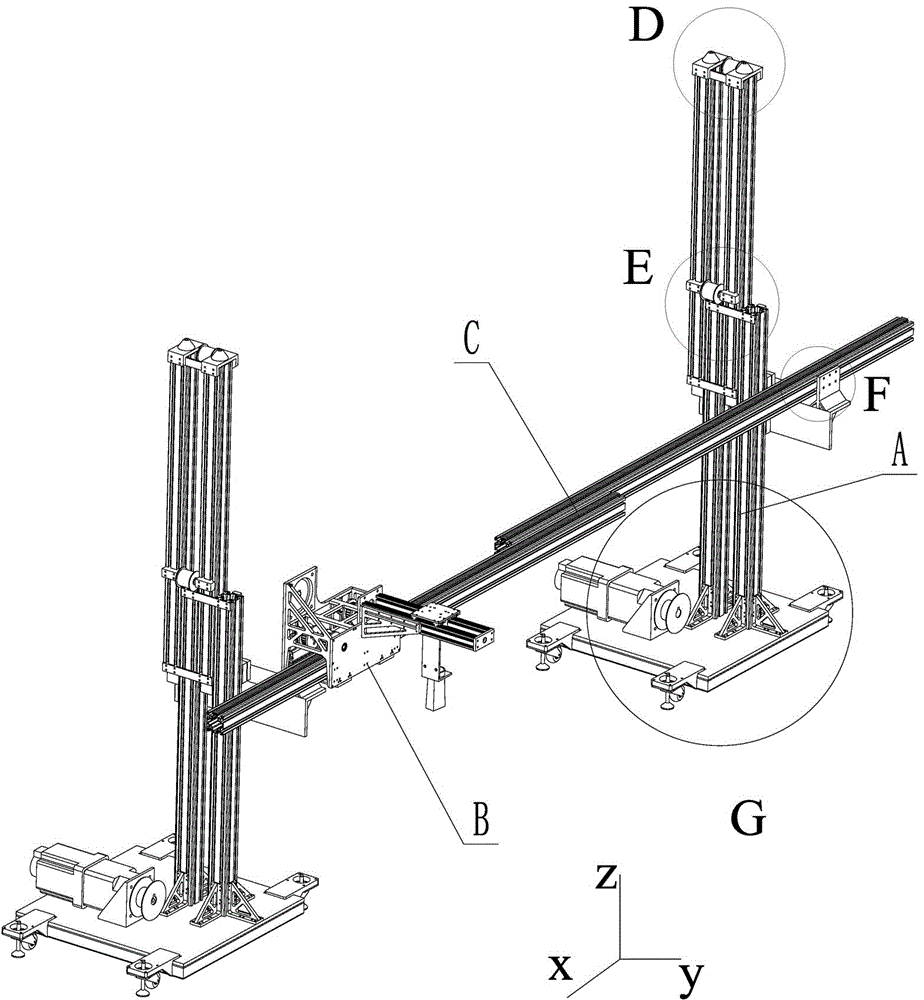

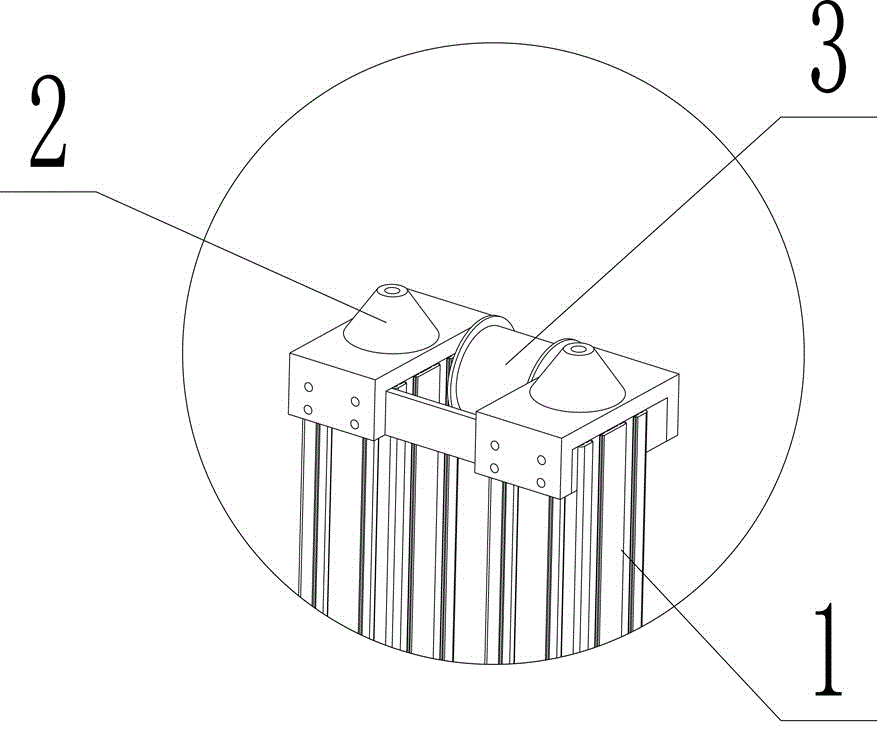

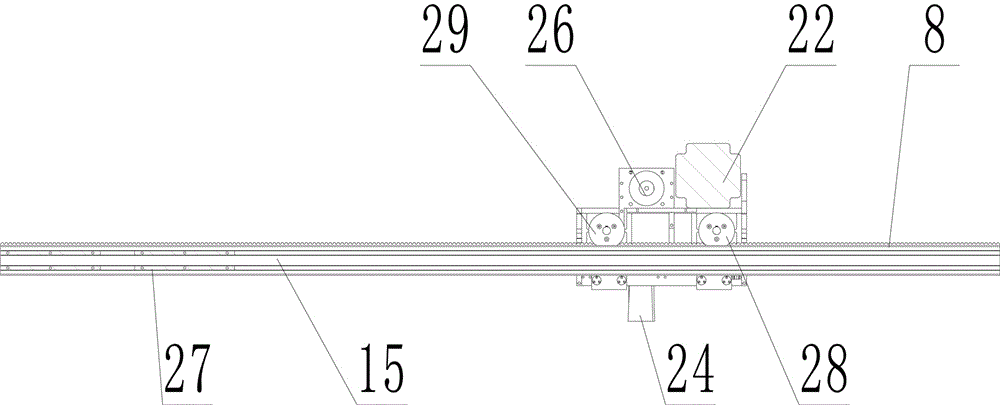

[0025] The following combination Figure 1~11 , the content of the present invention will be described in detail through specific embodiments. The full-range wrap-around printing head includes a support column module A, a beam module C limited on the support column module, a print head module B arranged on the beam module, and the like. Wherein, there are more than two support column modules, the number of beam modules is the same as the number of support column modules, and more than one print head module (this embodiment takes two support column modules, two beam modules and one print head module as an example).

[0026] Wherein, the support column module A includes a trolley assembly and a telescopic column assembly located on a horizontal plane. The trolley assembly includes a base 12, adjustable casters 13 arranged on the base (four adjustable casters are used as an example in this embodiment, which can be freely increased or decreased according to actual needs), and a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com