Fermenting method for removing aflatoxin in fermented bean curd rich in soybean polysaccharide

A technology of aflatoxin and soybean polysaccharide, applied in the field of food processing, can solve problems such as harmful organism pollution, and achieve the effects of multiple health care effects, increased nutritional value, and increased flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

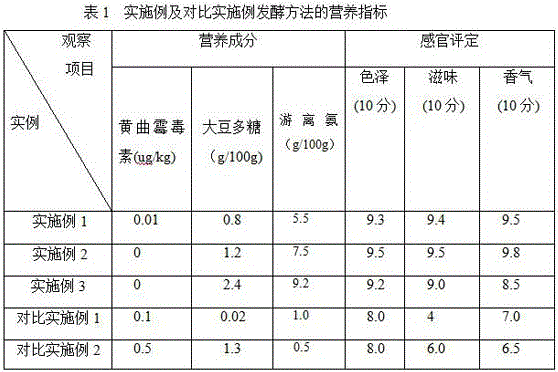

Examples

Embodiment 1

[0025] (1) Preparation of tofu cubes: take fresh tofu cubes and blanch them in boiling water for 1 min, and at the same time boil the fermenter in boiling water for 1 hour, and put them under sterile conditions for 2 hours;

[0026] (2) Add 3‰ flavor protease (enzyme activity: 15000U), 4‰ acid protease (enzyme activity: 9000U), 5‰ amylase (enzyme activity: 8000U) and 6‰ cellulase (enzyme activity: 10000U), enzymolysis at 28°C for 2h;

[0027] (3) Preparation of fermented liquid: respectively carry out Mucor, Rhizopus and Aspergillus niger cultures in liquid culture medium, mix Mucor fermented liquid, Rhizopus fermented liquid and Aspergillus niger fermented liquid by 1:1:4 after cultivating , to obtain the fermented liquid containing Mucor, Rhizopus and Aspergillus niger mycelia;

[0028] (4) Break the fermented liquid obtained in step (3) to obtain a mixed solution containing broken bacteria, adopt the method of spray inoculation, spray the bacterial suspension on the surfac...

Embodiment 2

[0032] (1) Preparation of tofu cubes: take fresh tofu cubes and blanch them in boiling water for 2 minutes, boil the fermenter in boiling water for 1.5 hours, and place them under sterile conditions for 3 hours;

[0033] (2) Add 3.5‰ flavor protease (enzyme activity: 15000U), 5‰ acid protease (enzyme activity: 9000U), 6‰ amylase (enzyme activity: 8000U) and 7‰ cellulase (enzyme activity: 10000U), enzymolysis at 30°C for 2.5h;

[0034] (3) Preparation of fermented liquid: respectively carry out Mucor, Rhizopus and Aspergillus niger culture in liquid culture medium, mix Mucor fermented liquid, Rhizopus fermented liquid and Aspergillus niger fermented liquid by 2:1:4 after cultivating , obtain the fermented liquid containing Mucor, Rhizopus, Aspergillus niger mycelium;

[0035] (4) Break the fermented liquid obtained in step (3) to obtain a mixed solution containing broken bacteria, adopt the method of spray inoculation, spray the bacterial suspension on the surface of the tofu ...

Embodiment 3

[0039] (1) Preparation of tofu cubes: take fresh tofu cubes and blanch them in boiling water for 2 minutes, simultaneously boil the fermenter in boiling water for 2 hours, and put them under aseptic conditions for 4 hours;

[0040] (2) Add 4‰ flavor protease (15000U enzyme activity), 6‰ acid protease (9000U enzyme activity), 8‰ amylase (8000U enzyme activity) according to the dry weight of tofu cubes. 8‰ cellulase (enzyme activity: 10000U), enzymolysis at 32°C for 3h;

[0041] (3) Preparation of fermented liquid: respectively carry out Mucor, Rhizopus and Aspergillus niger culture in liquid culture medium, mix Mucor fermented liquid, Rhizopus fermented liquid and Aspergillus niger fermented liquid by 2:2:4 after cultivating , obtain the fermented liquid containing Mucor, Rhizopus, Aspergillus niger mycelia;

[0042] (4) Break the fermented liquid obtained in step (3) to obtain a mixed solution containing broken bacteria, adopt the method of spray inoculation, spray the bacter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com