Method and system for controlling constant torque of switched reluctance motor by use of composite control current

A technology of switched reluctance motors and control methods, which is applied in control systems, control generators, vector control systems, etc., and can solve problems such as slow convergence speed, large torque ripple, and difficulty in adapting to the nonlinear characteristics of reluctance motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

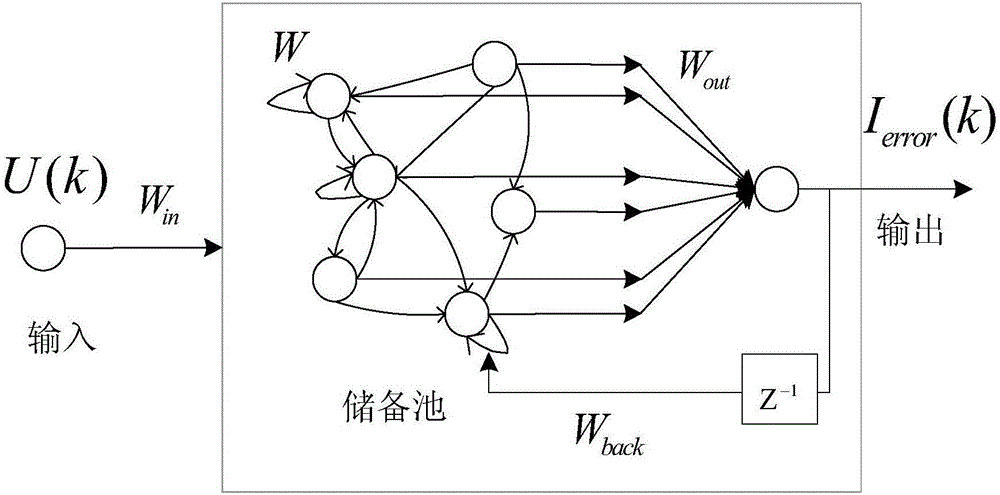

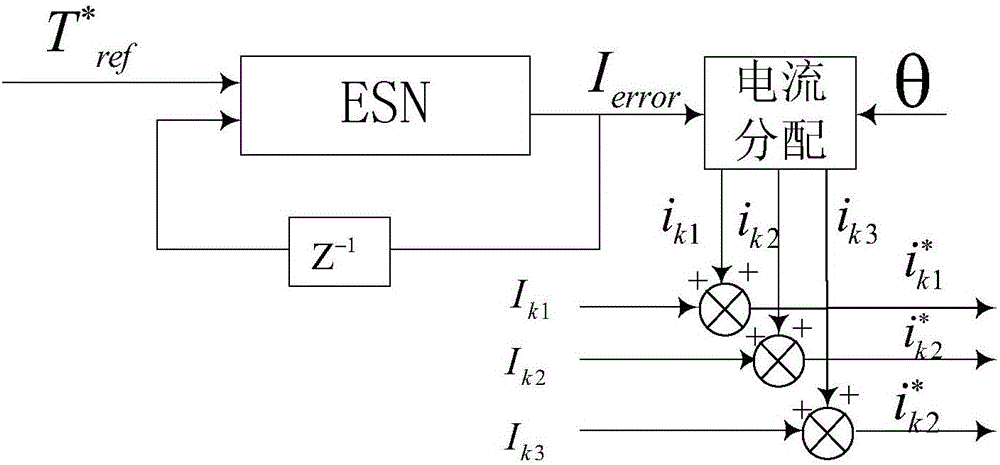

Image

Examples

Embodiment Construction

[0078] Embodiment of constant torque control method for switched reluctance motor with compound control current

[0079] The embodiment of the constant torque control method of the switched reluctance motor with compound control current, the main steps are as follows:

[0080] Ⅰ. Linear control current based on linear inductance model torque sharing function (TSF)

[0081] like figure 1 As shown, the linear inductance model control of switched reluctance motor includes three main parts: torque distribution, torque-current conversion and current hysteresis controller.

[0082] The switched reluctance motor adopts ideal linear inductance L of each phase kzz When , the torque-current conversion expression is:

[0083] I k z z = 2 T k z z d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com