Medium waveguide crack array antenna with series feed of metal hollow waveguide

A technology of waveguide feeding and array antenna, which is applied in the direction of slot antenna, antenna, antenna array, etc., can solve the problems of large loss, complex processing and welding process, large weight and size of metal hollow waveguide slot array antenna, etc., and achieve low loss , Improve the effect of surface utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

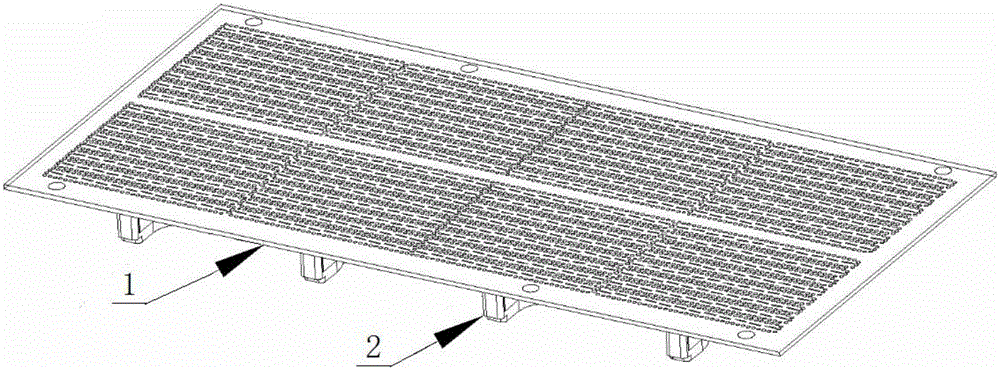

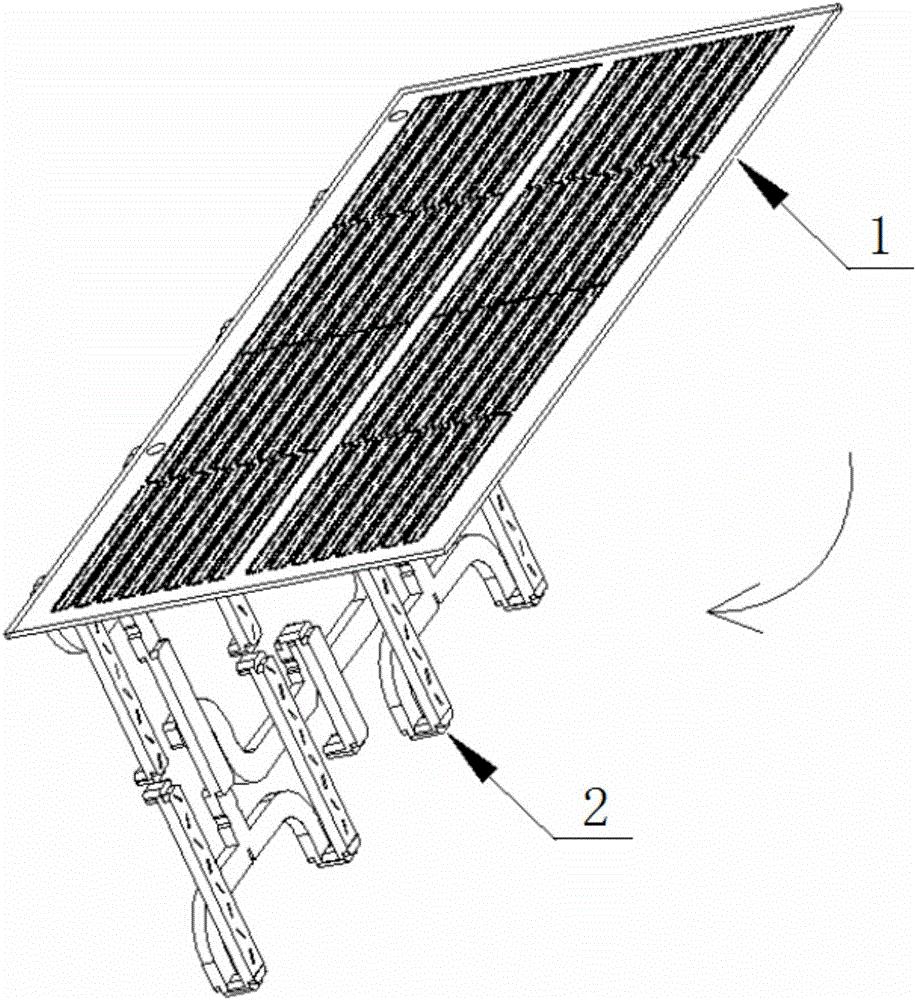

[0035] Embodiment 1: as figure 2 As shown, this embodiment provides a metal hollow waveguide feeding slot array antenna, including an antenna dielectric layer 1 and a metal hollow waveguide feeding device 2;

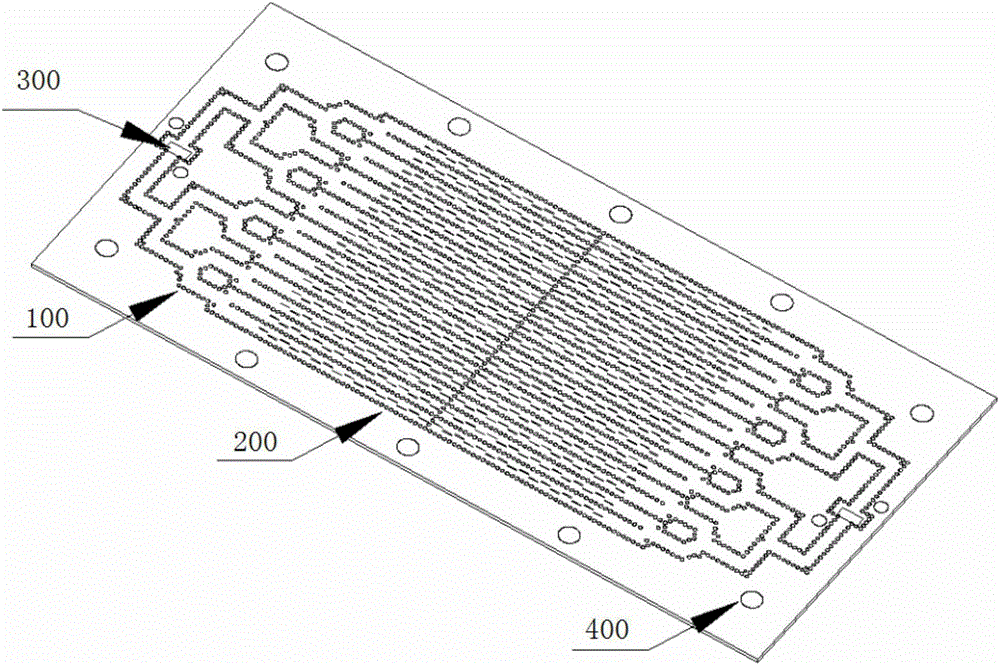

[0036] The antenna dielectric layer 1 includes an antenna radiation slot structure 11 and an antenna feeding slot structure 12 ; the antenna dielectric layer 1 is connected to the metal hollow waveguide feeding device 2 through the antenna feeding slot structure 12 . The antenna dielectric layer 1 is a substrate made of a common antenna dielectric material, which is used to allow electromagnetic waves to propagate therein; the radiation slots in the antenna radiation slot structure 11 and the feed slots in the antenna feed slot structure 12 are all according to the predetermined Arranged in a set way, generally, such as Figure 4a , Figure 4c As shown, the antenna feeding slot structure 12 forms an antenna feeding slot surface 15 on one surface (the following surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com