Robot spraying and track setting method for cabochon curved surface transition area between smooth curved surfaces

A technology for smoothing curved surfaces and transition areas, which is applied in the direction of instruments, spraying devices, design optimization/simulation, etc. It can solve problems such as unguaranteed product appearance quality, uneven coating thickness, rough spraying parameters, etc., and shorten the engineering debugging time , save paint, improve the effect of parameter setting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] 1. Use CATIA for surface partitioning

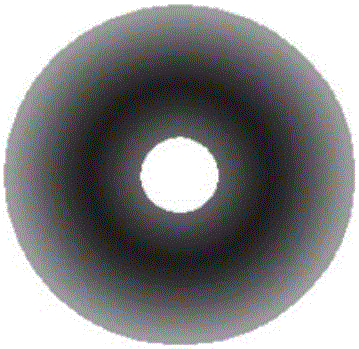

[0029] According to the arc surface of smooth surface (such as figure 1 As shown), the surface is divided into three parts by using CATIA drawing software (such as figure 2 As shown), the curved surface is part A, and the other two smooth surfaces are part B and C respectively. Using the CATIA function to analyze the curvature, the symmetrical center curve L1 of the surface A is obtained, and this center line is used as the reference line of the spraying trajectory in the transition area between the smooth curved surface and the curved surface. Similarly, use the CATIA function for curvature analysis to obtain the boundary line L2 between surface B and surface A, and the boundary line L3 between surface C and surface A.

[0030] 2. Use the test method to obtain a plane coating thickness cumulative model, and establish the relationship between the parameters of the spray gun and the cumulative thickness of the coating through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com