Weld seam fatigue life calculation method based on total strain energy density

A strain energy and fatigue life technology, applied in calculation, design optimization/simulation, special data processing applications, etc., can solve problems such as low prediction accuracy and calculation efficiency, and achieve the effect of avoiding position and orientation problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0049] An example of fatigue life calculation of a certain mechanical structure weld seam is given below, but the scope of protection of the present invention is not limited to the following implementation examples.

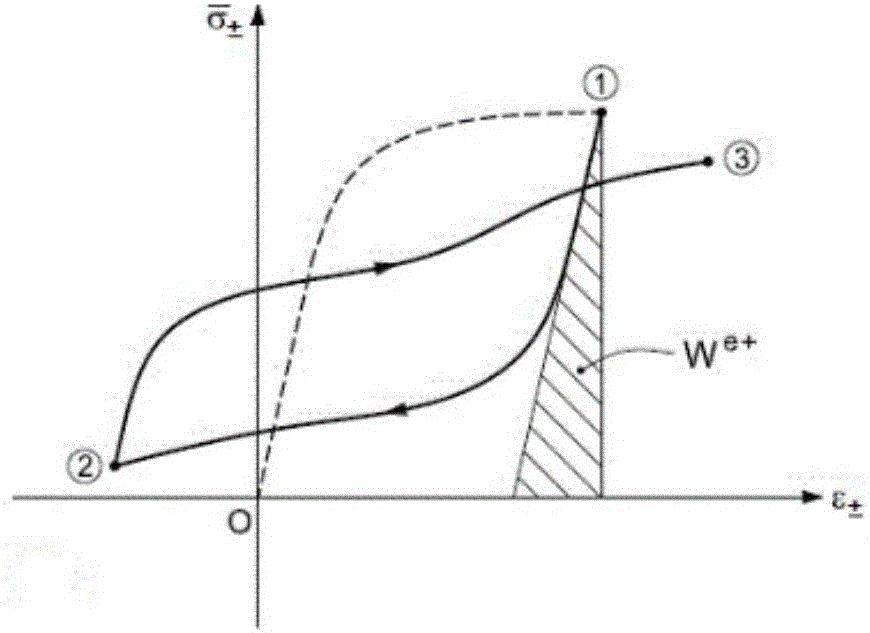

[0050] see figure 1As shown, (1) The normal stress-strain curve and the shear stress-strain curve under the action of weld tension-compression and torsional cyclic loads are respectively obtained through the fatigue performance test of the welded joint material, and calculated according to the normal stress-strain curve and the shear stress-strain curve Positive elastic strain energy density ΔW e+ :

[0051] ΔW e + = 1 2 σ ¯ ± · ε ± e = ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com