Lifting device for checking and detecting inventory power equipment

A technology of electric equipment and live detection, which is applied in the direction of measuring devices, parts of electrical measuring instruments, cranes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

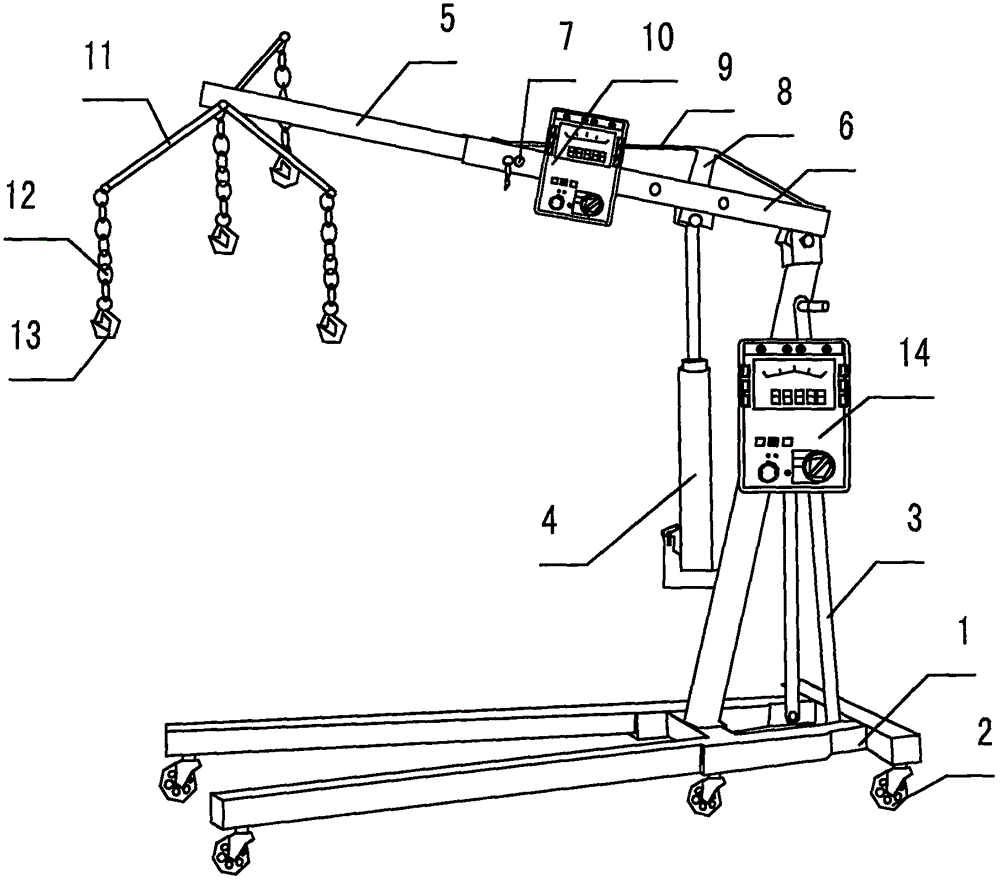

[0017] Example: see attached figure 1 , 2 , a hoisting device for inspection and testing of electric equipment in stock, is provided with a movable chassis 1, and a plurality of universal casters 2 are installed under the movable chassis, and the movable chassis is a "open"-shaped structure Underframe, the structural underframe of the "open" shape is fixed with three columns 3 at the upper end of the "open" shape, the three columns are distributed in a three-legged tripod, and a cantilever beam is hinged at the top of the three columns, and the cantilever crane The middle part of the beam is hingedly supported by a hydraulic support rod 4 and one of the three columns. The cantilever suspension beam is divided into a front end extension beam 5 and a rear end support fixed beam 6. The rear end support fixed beam is a hollow tubular structure The fixed hole 7 and the fixed pin are arranged on the said rear-end supporting fixed beam, and the said front-end extension beam can be e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com