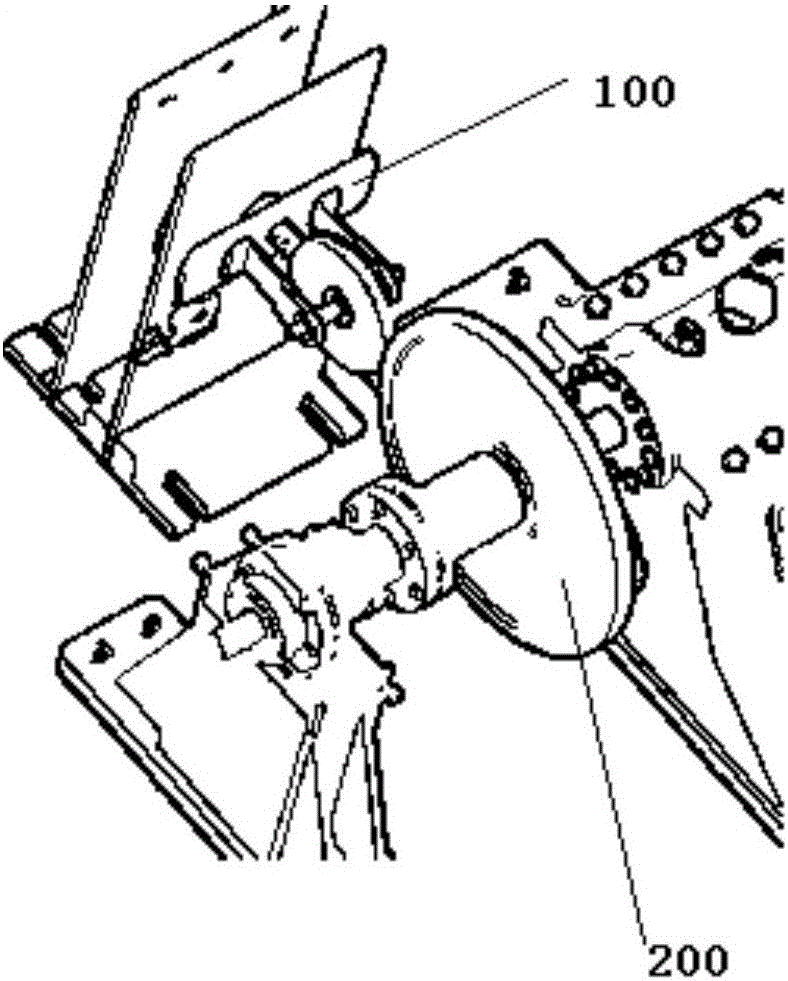

Device and method for measuring transient sliding friction coefficient based on fiber grating

A technology of sliding friction coefficient and optical fiber grating, which is applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of inability to achieve accurate measurement, inability to distinguish the change of Bragg wavelength, etc., and achieve the effect of solving cross-sensitivity problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

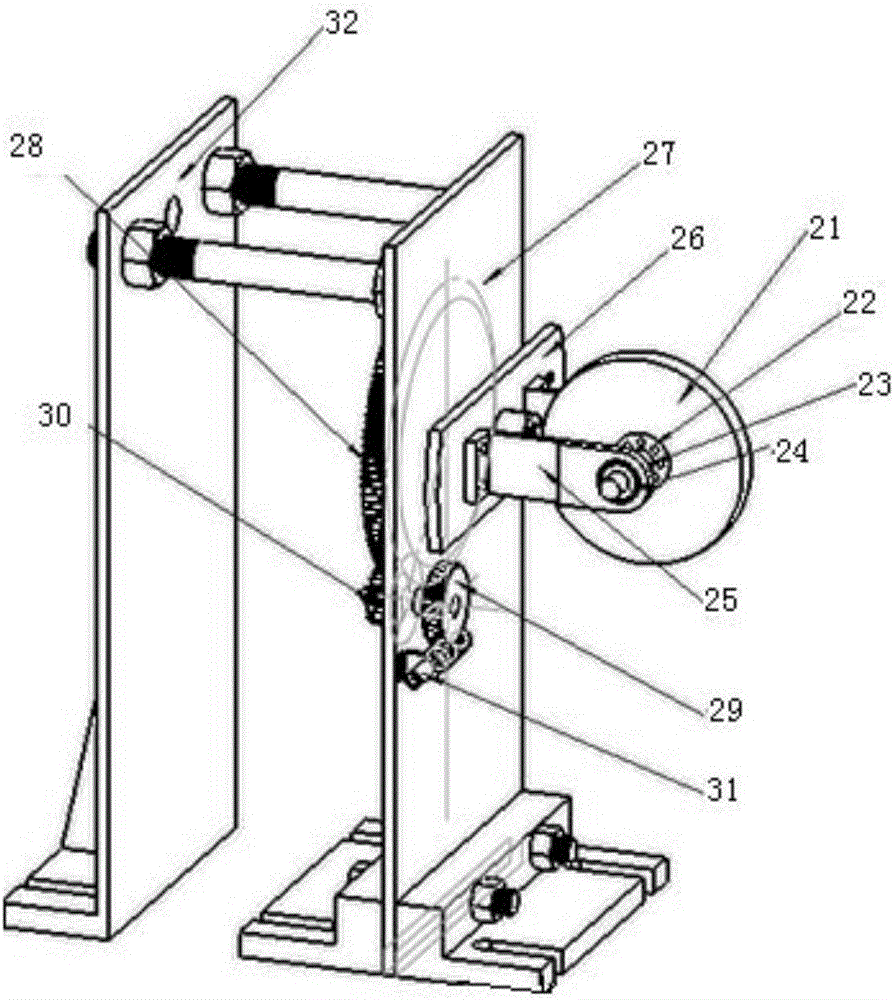

[0040] In order to make the objectives, technical solutions and advantages of the present invention clearer, the following further describes the present invention in detail with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, but not to limit the present invention.

[0041] The present invention draws on the double grating method and adopts the symmetrical arrangement of two fiber gratings on the front and back of the element to eliminate the influence of temperature. When the temperature rises, their temperature rises at the same time. When the element is stressed, the grating is in front and back. , So a grating is stretched, the center wavelength increases, and a grating is compressed center wavelength decreases.

[0042] Δλ B =K T ·ΔT+K ε ·Δε (1-3)

[0043] Using formula 1-3, the two fiber gratings pasted in the same temperature environment are affected b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| Poisson's ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com