Method for controlling electric exhaust gas bypass valve of turbocharged engine

A wastegate valve and turbocharging technology, applied in engine control, electrical control, combustion engine, etc., can solve problems such as unstable engine operation and sudden increase in boost pressure, to avoid unstable torque control and prevent increase. The effect of excessive pressure and improving transient response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

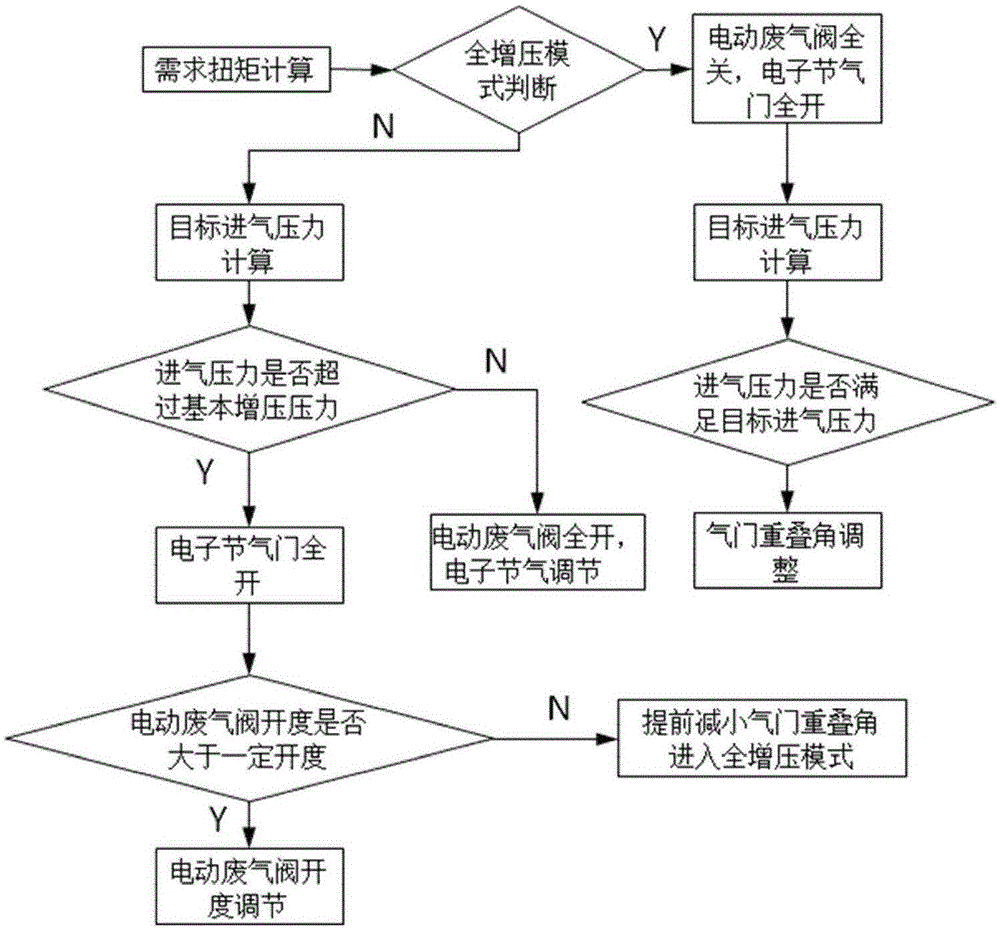

[0032] In a preferred embodiment, a turbocharged engine electric wastegate valve control method, the present invention is a kind of torque model structure of the engine electronic control system on the control of boost pressure, the problem to be solved by the patent of the present invention is, for Avoid the turbocharger wastegate valve being too sensitive to the intake pressure at a small opening, resulting in pressure fluctuations, resulting in unstable engine operation control. Combined with the existing electronically controlled torque structure model, this patent has invented a control strategy for the electric wastegate valve. The control strategy judges whether the engine is in full boost mode by judging the operating conditions of the engine. If it is in full boost In the mode, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com