Mechanical Vertical Pole Installation Method of Polyurethane Composite Pole

A technology of composite materials and installation methods, applied in building types, buildings, towers, etc., can solve the problems of bulky poles, cracks in the poles, difficult transportation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

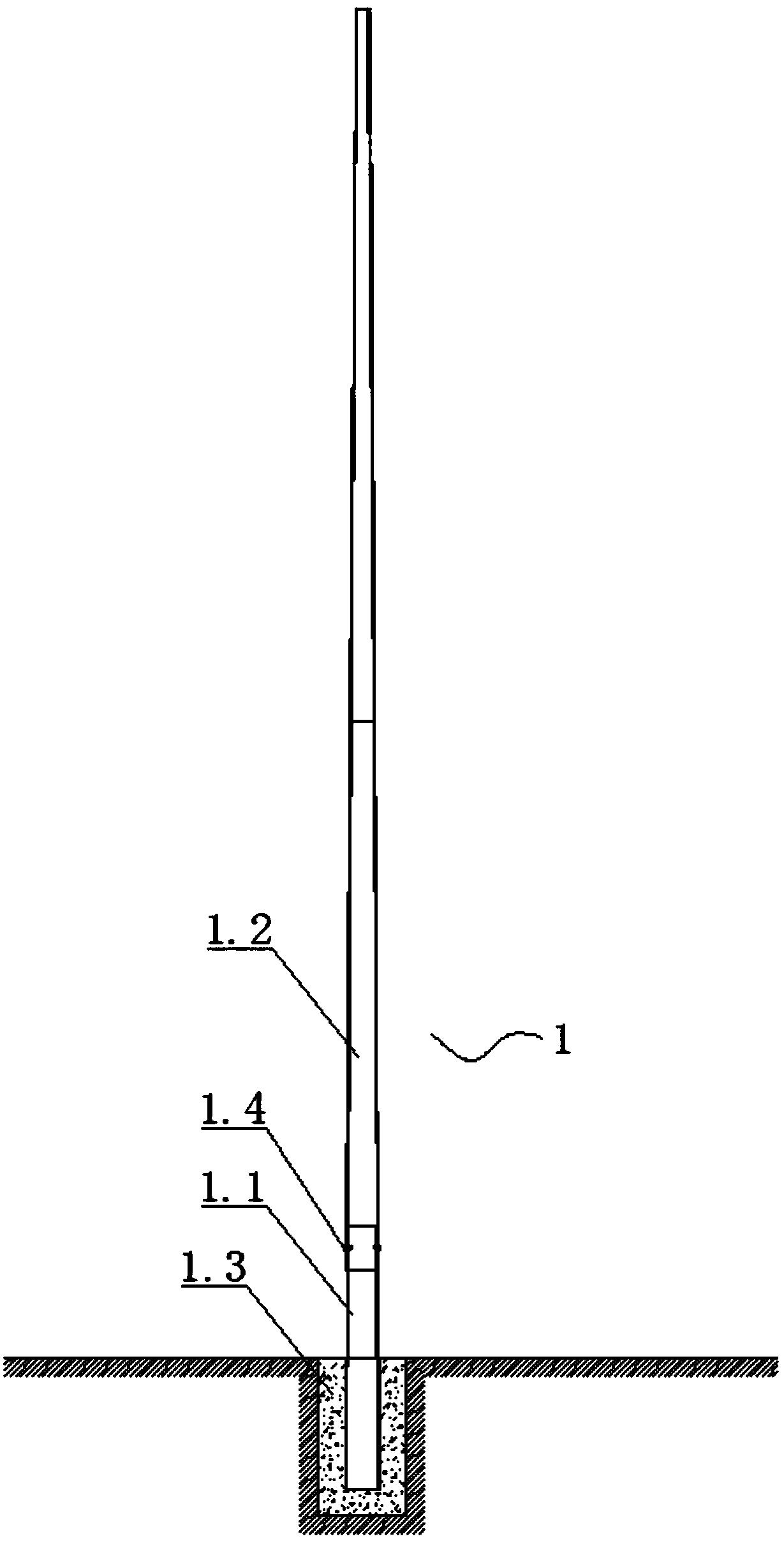

[0037] see figure 1 , a polyurethane composite pole 1 related to the present invention, which includes a pre-embedded pole tower 1.1 and a standard pole tower 1.2. The lower half of the buried tower 1.1 is buried in the foundation 1.3, the lower end of the standard tower 1.2 is sleeved on the upper end of the pre-embedded tower 1.1, and the standard tower 1.2 and the pre-embedded tower 1.1 are connected by multiple bolts 1.4 The two are fastened, and the inner wall of the standard tower 1.2 and the outer wall of the pre-embedded tower 1.1 are filled with adhesive at the joints of the two. A universal level is provided at the upper hollow of the pre-embedded tower 1.1, and the universal level is used to detect the verticality of the pre-embedded tower 1.1.

[0038] A pole installation structure made of polyurethane composite materials. A pit with a depth of 2000mm is dug on the surface of the installation site, and a foundation 1.3 is poured in the pit. A 1500mm-deep insertion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com