Acrylate polymer emulsion containing pigment particles and preparation method thereof

A technology of polymer emulsion and pigment particles, which is applied in the field of textile printing and dyeing, can solve the problems of low wrapping efficiency, low dry and wet rubbing fastness and soaping fastness of paint-dyed fabrics, non-stick rollers, fabric feel and environmental safety. Satisfy other problems, achieve the effect of improving dry and wet rubbing fastness and soaping fastness, increasing polymerization stability and storage stability, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

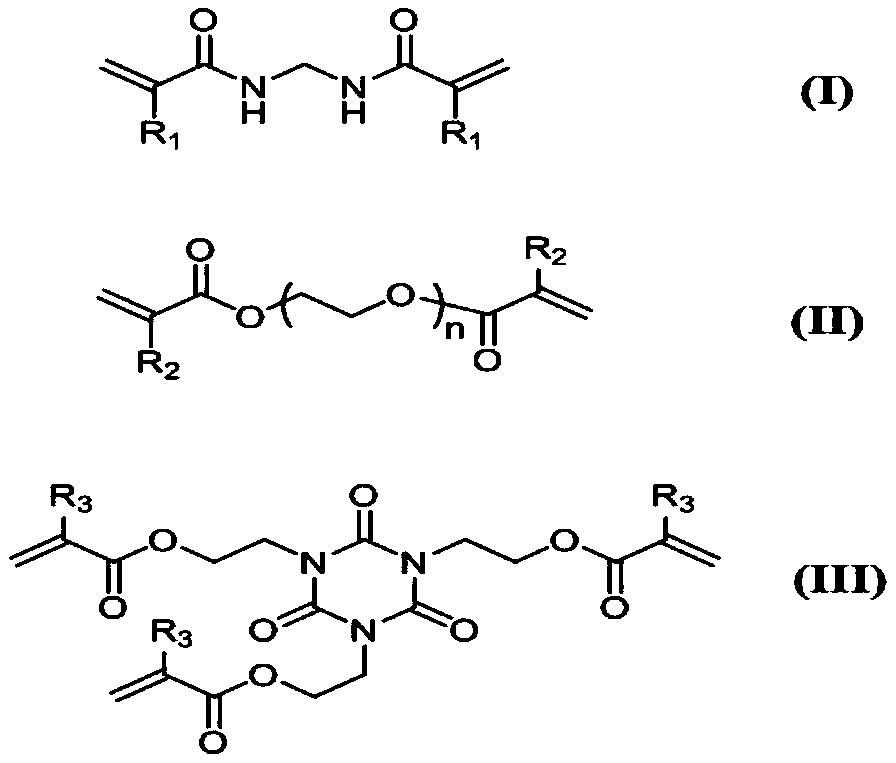

Method used

Image

Examples

Embodiment 1

[0034] The preparation of the intermediate layer monomer miniemulsion containing pigment particles: add 1.4g sodium dodecylsulfonate anionic surfactant, 3.9g Tween-80 (polyoxyethylene (20) sorbitan mono-oil Ester nonionic surfactant, from Haian Petrochemical Plant, Jiangsu Province), 87g deionized water and 20g pigment blue 15:3, after grinding at 3600r / min until the average particle diameter of the pigment is less than 200nm, add 29.5g butyl acrylate, A mixture of 14.5g methyl methacrylate, 0.22g acrylic acid, 0.1g N,N-methylene bisacrylamide and 0.88g n-hexadecanol, continue to grind and finely emulsify for 1 hour to obtain the intermediate layer monomer containing pigment particles fine emulsion;

[0035] The preparation of the shell monomer pre-emulsion: add 1.3g sodium dodecyl sulfonate, 3.9g Tween-80 (polyoxyethylene (20) sorbitan monooleate nonionic surfactant in a 250mL three-necked flask , from Jiangsu Haian Petrochemical Factory), 87g deionized water, after stirring...

Embodiment 2

[0041] The preparation technology of colored emulsion is the same as embodiment 1, and its formula is composed as follows:

[0042] The intermediate layer monomer miniemulsion containing pigment particles: 2.6g sodium cetyl sulfonate anionic surfactant, 5.2g Tween-20 (polyoxyethylene (20) sorbitan monolaurate nonionic surfactant , from Jiangsu Haian Petrochemical Plant), 85g deionized water, 28g Pigment Blue 15:3, 60g isooctyl acrylate, 12g isobornyl methacrylate, 0.87g methacrylic acid, 0.58g ethylene glycol dimethyl Acrylate, 1.47g n-hexadecanol;

[0043] Shell monomer pre-emulsion: 1.3g sodium cetyl sulfonate, 2.6g Tween-20 (polyoxyethylene (20) sorbitan monolaurate nonionic surfactant, from Jiangsu Haian Petrochemical plant), 63g deionized water, 18g isooctyl acrylate, 23.4g isobornyl methacrylate, 0.29g methacrylic acid, 2.3g hydroxyethyl methacrylate;

[0044] Initiator aqueous solution: 0.53g ammonium persulfate dissolved in 20g water, 0.27g sodium bisulfite dissolved...

Embodiment 3

[0048] The preparation technology of colored emulsion is the same as embodiment 1, and its formula is composed as follows:

[0049] The intermediate layer monomer miniemulsion containing pigment particles: 2.9g sodium lauryl sulfate anionic surfactant, 2.9g AEO-7 (fatty acid alcohol oxyethylene (7) ether nonionic surfactant, from Haian Petrochemical Industry, Jiangsu Province factory), 40g deionized water, 5g Pigment Blue 15:3, 66g lauryl acrylate, 5.5g benzyl methacrylate, 3.2g itaconic acid, 0.95g polyethylene glycol diacrylate (n=9), 1.51g n-hexadecanol;

[0050] Shell monomer pre-emulsion: 0.8g sodium lauryl sulfate, 0.8g AEO-7 (fatty acid alcohol oxyethylene (7) ether nonionic surfactant, from Jiangsu Haian Petrochemical Plant), 15g deionized water , 3.8g lauryl acrylate, 11.3g benzyl methacrylate, 0.64g itaconic acid, 2.8g diacetone acrylamide;

[0051] Initiator aqueous solution: 0.5g ammonium persulfate dissolved in 35g water, 0.5g sodium bisulfite dissolved in 35g w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emulsion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com