Corner adjustable type wastewater treatment biochemical reactor

A biochemical reactor, wastewater treatment technology, applied in water treatment parameter control, biological water/sewage treatment, water/sludge/sewage treatment, etc. Compact, well-designed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

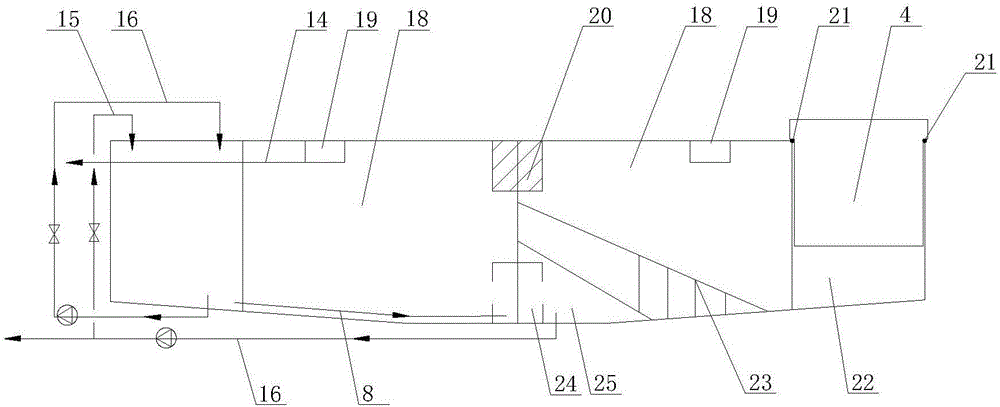

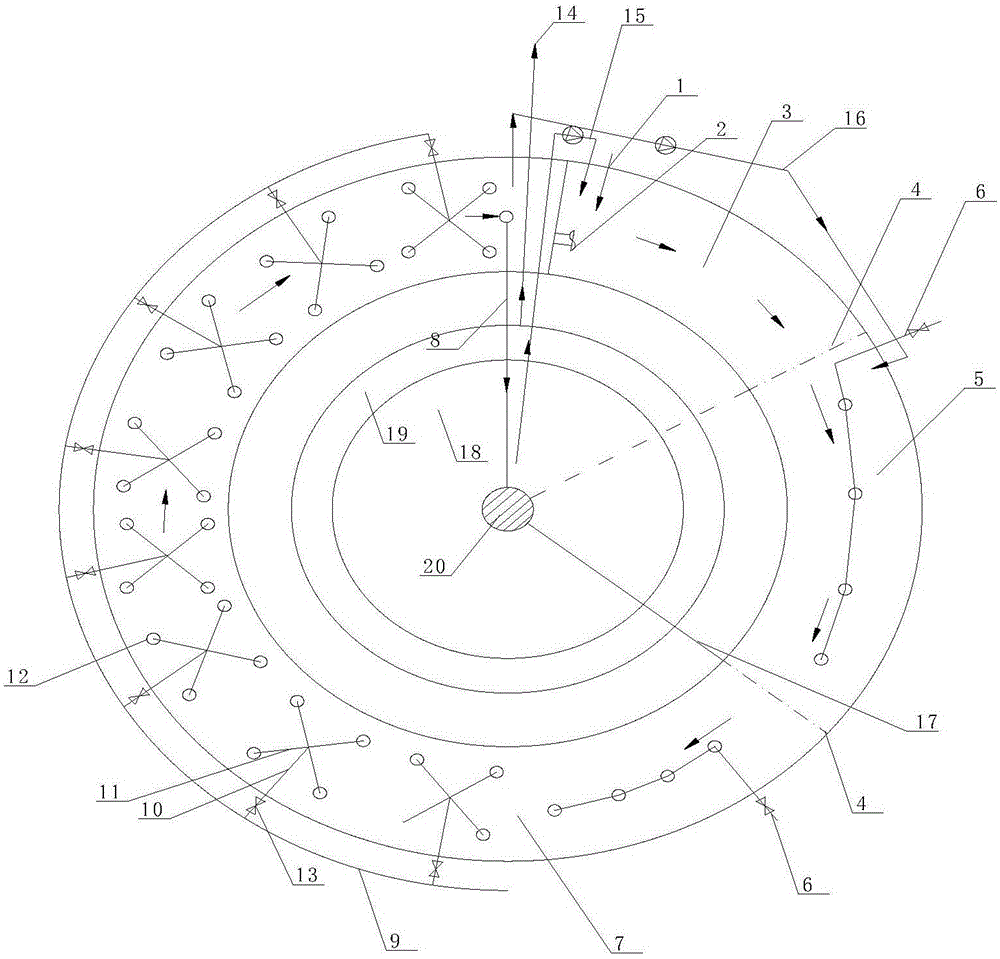

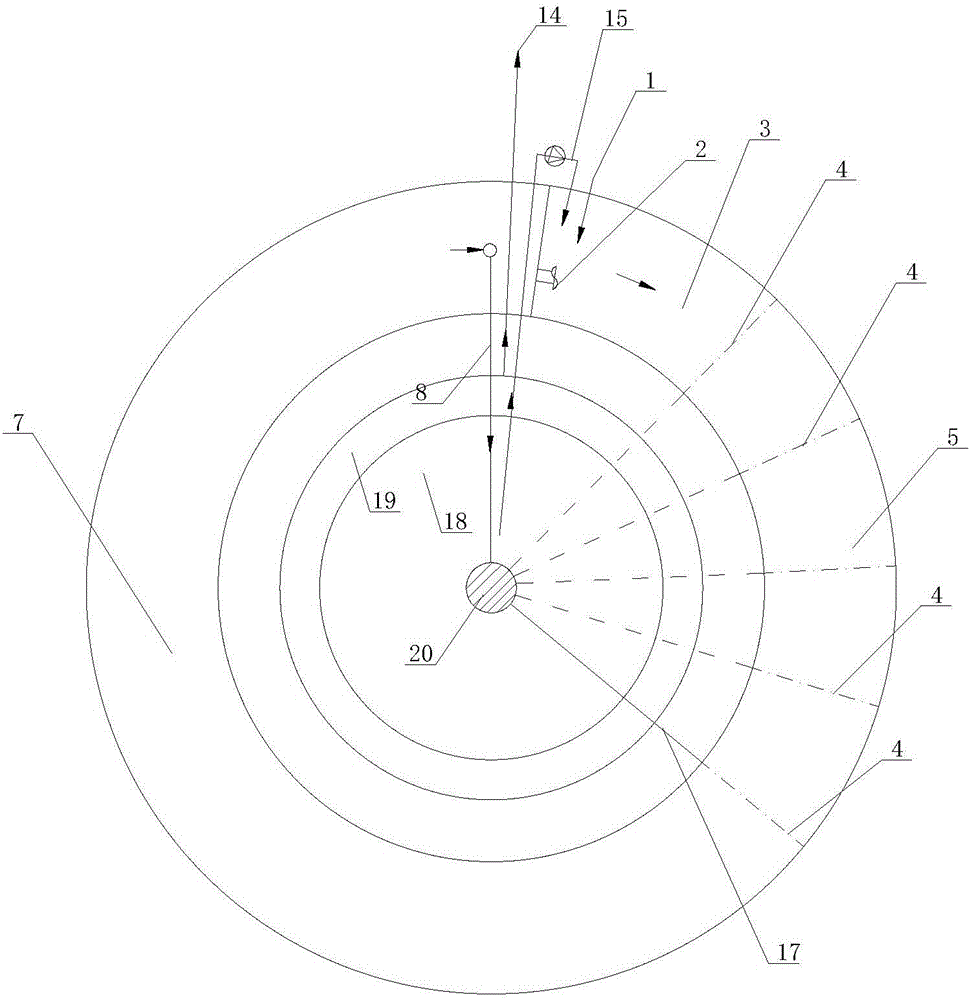

[0040] Such as figure 1 and figure 2 As shown, a biochemical reactor for wastewater treatment with adjustable rotation angle, the reactor is in the form of a circular corridor, and a continuous water passage corridor of equal width and height is provided, which is allocated as an anaerobic section 3. Oxygen section 5 and aerobic section 7, wherein along the direction of waste water flow, 2 moving partitions 4 are set on the starting corridor, slide rails 21 are set on the wall of the annular corridor, and a transmission device 20 is arranged at the annular center of the biochemical reactor. The rotary arm 17 is rotated, and the rotary arm 17 is connected with the movable partition 4 on the slide rail 21 , and the distribution and adjustment of the volume of each segment is realized by moving the partition 4 . The lower or upper part of the movable partition 4 is provided with a water passing hole 22 .

[0041] In the biochemical reactor with adjustable rotation angle for wa...

Embodiment 2

[0046] The reactor provided by the present invention is used to treat general industrial wastewater. The design and layout of the reactor passageway and the separation mode of each biochemical reaction section, the operation control mode and parameters of the reactor and the aeration device are the same as in Example 1. . The difference from Example 1 is that different distribution volume ratios of anaerobic section, anoxic section and aerobic section are adopted for different treatment objects.

[0047]For the treatment of refractory industrial wastewater, the water quality indicators of industrial wastewater before treatment: COD is 1000-3000mg / L, ammonia nitrogen is about 30mg / L, and total phosphorus is about 5mg / L. Using the above-mentioned rotary adjustable anaerobic -The anoxic-aerobic biochemical reactor needs to prolong the relative hydraulic retention time of the anaerobic section and strengthen the effect of biochemical treatment in the anaerobic section. 3:2:7 or 4...

Embodiment 3

[0049] The reactor provided by the present invention is used to treat high-phosphorus wastewater. The design and layout of the reactor passageway and the separation mode of each biochemical reaction section, the operation control mode and parameters of the reactor and aeration device are the same as in Example 1. . The difference from Example 1 is that different volume ratios of anaerobic section, anoxic section and aerobic section are adopted for different treatment objects.

[0050] For the treatment of high-phosphorus wastewater, the water quality indicators of industrial wastewater before treatment: COD (chemical oxygen demand) is 400-1000mg / L, ammonia nitrogen is about 10mg / L, and total phosphorus is about 20mg / L. Using the above-mentioned rotary type can Adjusting the anaerobic-anoxic-aerobic biochemical reactor requires phosphorus removal, prolonging the relative hydraulic retention time of the anaerobic section and the aerobic section to facilitate anaerobic phosphorus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com