Hoisting mounting method and hoisting mounting fixture for torsional vibration damper

A technology for torsional vibration dampers and installation tooling, which is applied in the directions of transportation and packaging, load hanging components, etc., can solve the problem of reducing the installation efficiency of torsional vibration dampers, increasing the difficulty of assembly, and difficult to install holes for torsional vibration dampers. Aligning the through hole of the crankshaft, etc., to achieve the effect of simple and easy lifting and installation method, improve installation efficiency, and ensure lifting safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with drawings and embodiments.

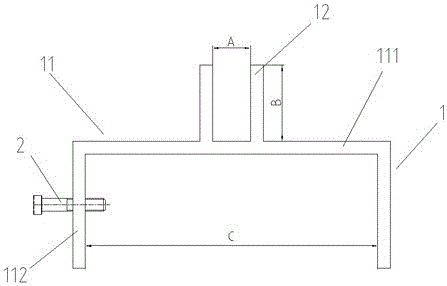

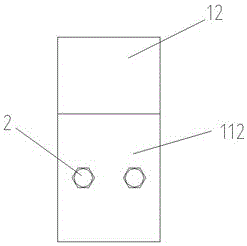

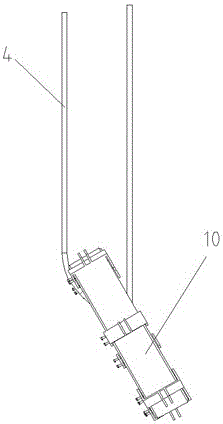

[0033] Such as figure 1 with figure 2 As shown, the torsional vibration damper lifting installation tooling of the present invention includes 6 lifting brackets 1 uniformly fixed on the circumferential edge of the torsional vibration damper 10 and 2 fastening screws 2 fixed on one side of the bracket, lifting The bracket 1 is a welded part in a convex shape, including a groove-shaped lower clamping seat 11 and a pair of lifting wire rope splints 12 vertically extending upward from the upper longitudinal middle of the lower clamping seat 11. The lower clamping seat 11 includes a fixed and integrated The upper top board 111 and the lower side boards 112 on both sides. The lower clamp seat 11 is clamped on the edge of the torsional vibration damper 10 in the circumferential direction, and the ends of at least two fastening screws 2 respectively pass through a lower side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com