Active-driving grinding device

A grinding device and active drive technology, applied in grinding devices, abrasive surface adjustment devices, grinding machine tools, etc., can solve the problems of low grinding precision cost, low grinding precision, non-active driving, etc., and achieve low machine equipment cost and processing time. Controllable and quality-improving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

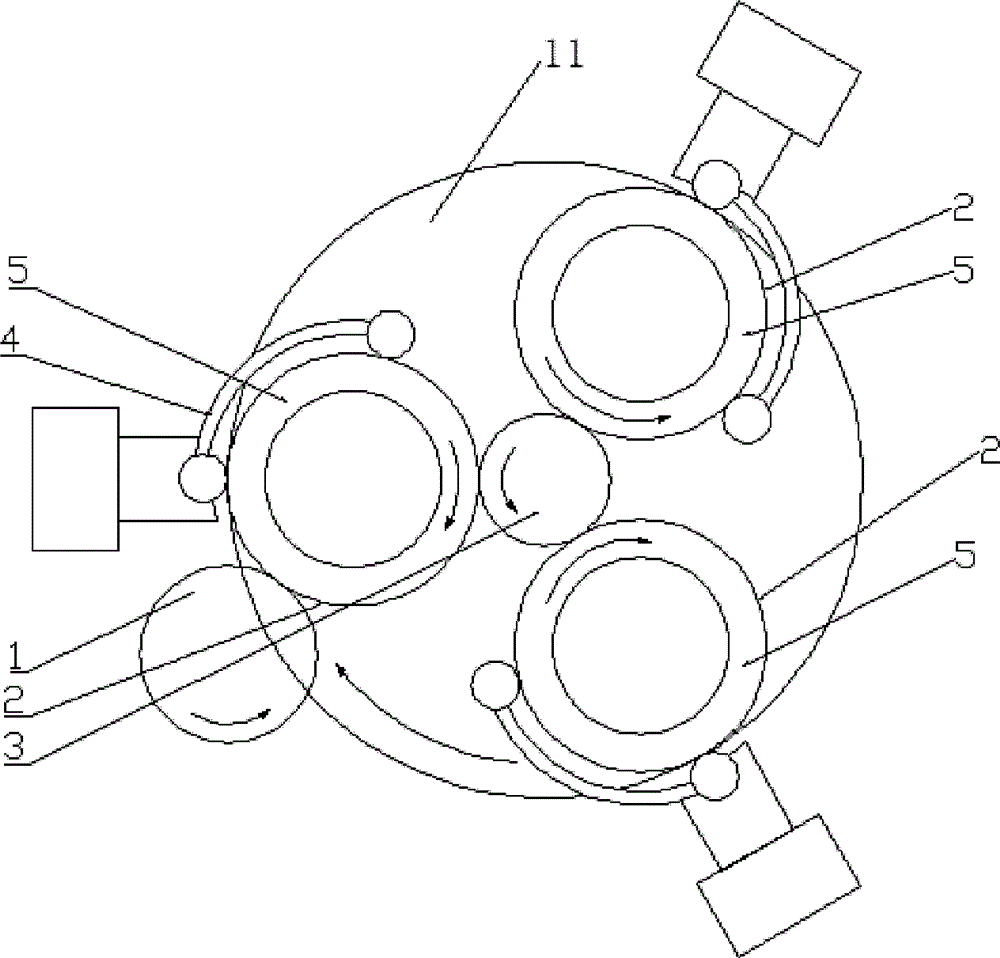

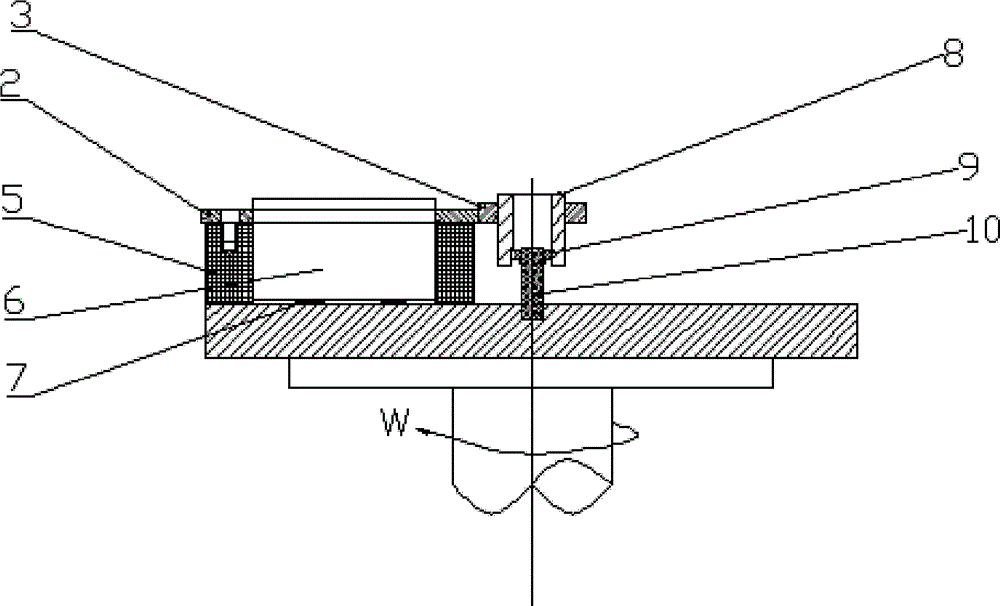

[0021] refer to figure 1 and figure 2 , a kind of active driving grinding device, including trimming ring 5, base disc 6 and grinding disc 11, also includes driving motor, output gear 1, 3 force bearing gears 2 and auxiliary gear 3 that can rotate freely; Said driving motor is installed On the base, the output gear 1 is connected to the drive motor and meshed with the stressed gear 2; the stressed gear 2 is fixedly connected to the trimming ring 5 by bolts, and the trimming ring 5 is passed through The trimming ring fixture 4 is fixed on the grinding disc 11 and can rotate around the fixed center line; the base disc 6 is stuck in the trimming ring 5; a threaded hole is provided in the middle of the grinding disc 11; the auxiliary gear 3 is located at the center of the three force-bearing gears 2 and all mesh with the force-bearing gears 2, and the lower part of the auxiliary gear 3 is fixed on the grinding disc 11 through the threaded hole.

[0022] Further, the auxiliary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com