Splicing method for curved single-tower double-cable-plane frameworks for cable-stayed bridge main tower

A double-cable-plane, cable-stayed bridge technology, applied in bridges, bridge construction, bridge parts, etc., can solve the problems of non-recyclable materials, difficult on-site processing, heavy metal formwork, etc., and achieve safe and reliable fixed connections, convenient assembly, and lighten The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

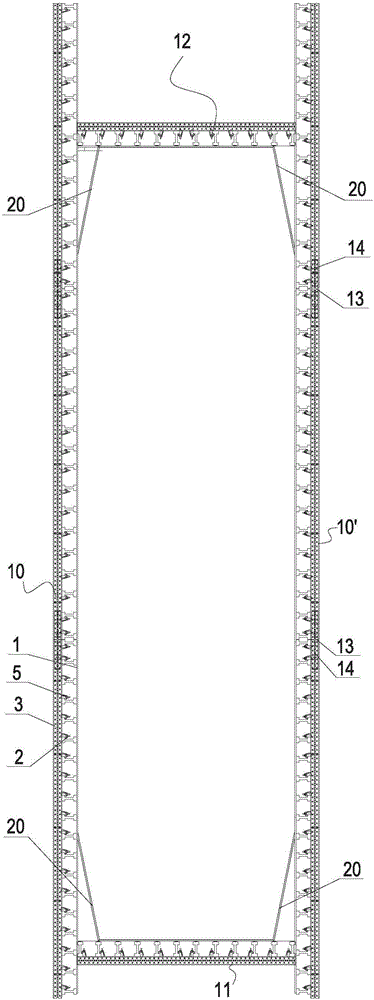

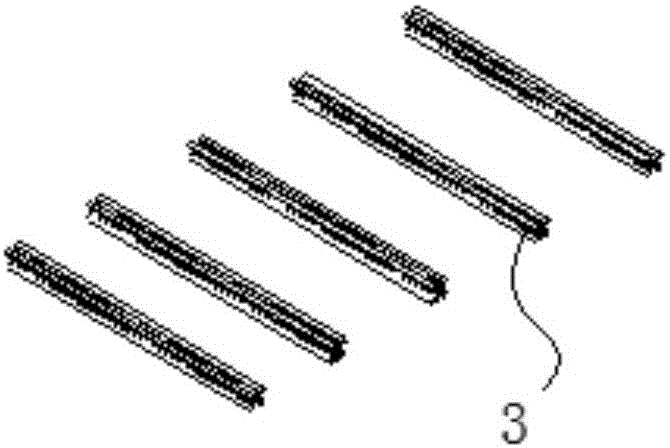

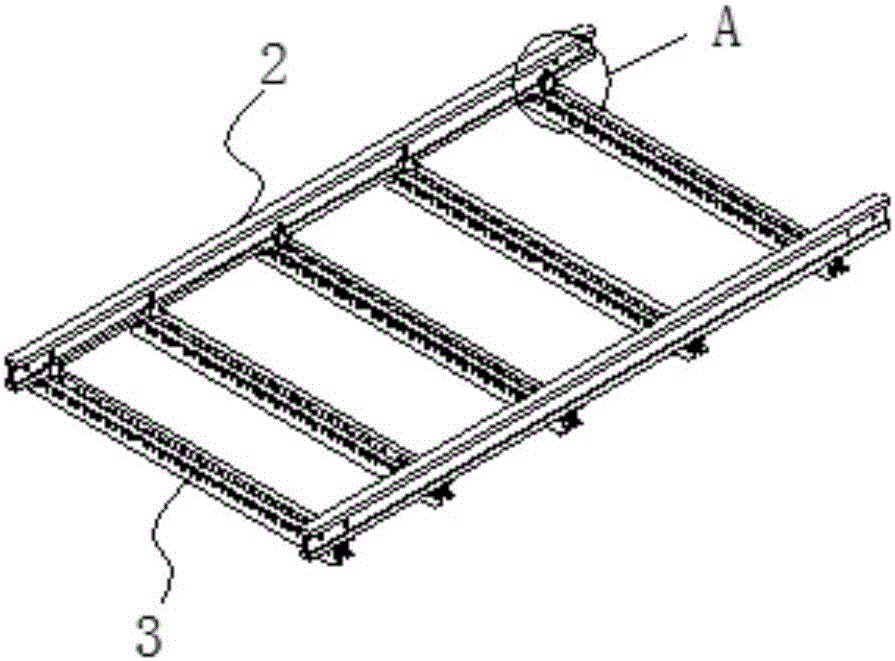

[0030] see first figure 1 , the formwork for the main tower of the cable-stayed bridge with single-tower and double-cable surfaces includes two side formworks 10, 10', a formwork 11 for the face of the cable, a formwork 12 for the back-cable surface, and a corner formwork 20; the formwork for the two side forms 10, 10' is Plane formworks with the same structural size are arranged parallel to each other; the formwork 11 and the formwork 12 of the back-cable surface are arc-surface formworks with different curvatures and are relatively connected between the two side formworks 10, 10'; the angle formwork 20 It is located between the two side formworks 10, 10' and the formwork 11 and the formwork 12 of the back-cable surface respectively. The side formwork 10 is formed by splicing two planar formwork units through a core strip 13 and a core strip pin 14 . Each planar formwork...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com