Tensioner for belt conveyor

A technology of tensioner and belt conveyor, which is applied in the direction of conveyor, transportation and packaging, etc., can solve the problems of reduced production efficiency, inconvenient operation, long conveyor belt, etc., and achieves extended service life, convenient operation, production and processing simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

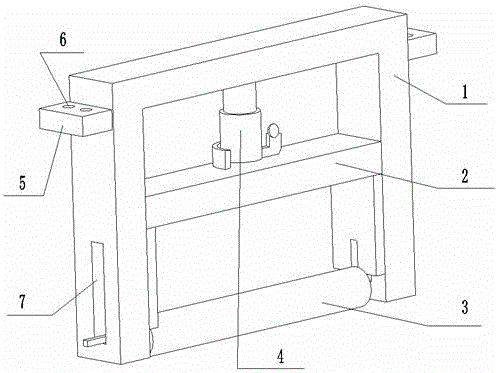

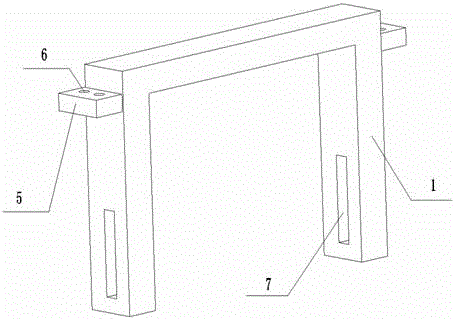

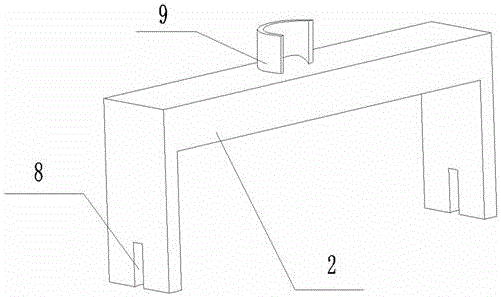

[0018] Such as Figure 1 to Figure 4 As shown, a tensioner for a belt conveyor of the present invention includes a bracket body 1, a tension body 2, a tension shaft 3 and a telescopic adjuster 4, and the bracket body 1 and the tension body 2 are in the shape of a door frame structure, the tensioning body 2 is embedded inside the support body 1 of a door-shaped frame structure, the tensioning shaft 3 is located at the bottom of the tensioning body 2, and is in contact with the conveyor belt, and the telescopic adjuster 4 is arranged on Between the support body 1 and the tension body 2, the distance between the support body 1 and the tension body 2 is adjusted by the telescopic adjuster 4 .

[0019] Further, hanging lugs 5 are provided on the outer surfaces of both sides of the bracket body 1, and fixing holes 6 are arranged on the lifting lugs 5, and the bracket body 1 is fixed on the transportation through the fixing holes 6 through the connecting bolts. on the strap support....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com