Rail vehicle head-car structure

A rail vehicle and head car technology, applied in the field of rail vehicle head car structure, can solve the problems of limited length and shape of the arc section of the hood, forward movement of the inflection point of the arc of the hood, unfavorable shape design, etc., and achieve good resistance to longitudinal and the intensity of the vertical force, the large amount of adjustment in the longitudinal direction, and the effect of reducing the degree of strength dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below with reference to the accompanying drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other. For the convenience of description, if the words "up", "down", "left" and "right" appear in the following, it only means that the directions of up, down, left and right are consistent with the drawings themselves, and do not limit the structure.

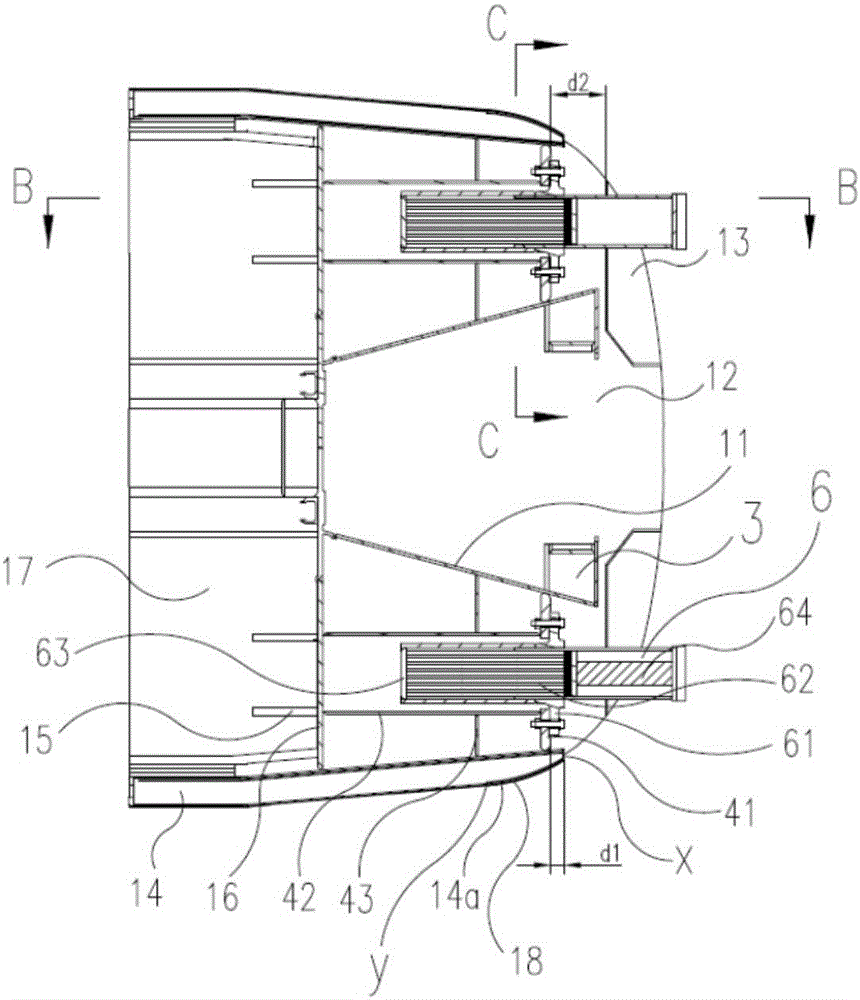

[0048] A rail vehicle head car, such as figure 1 As shown, it is mainly composed of the main body structure 1, the driver's cab frame 2, the column gusset 3 and the anti-climber installation structure 4 through welding. The main vehicle body structure 1 mainly includes basic components such as the top cover, side walls, underframe, and end walls of the passenger compartment area. The underframe of the present invention extends to the driver's cab area, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com