Canvas stretching and nailing device

A canvas and cloth clip technology, applied in special decorative structures, decorative arts and other directions, can solve the problems of high labor cost, time-consuming and laborious, and poor quality of the frame.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

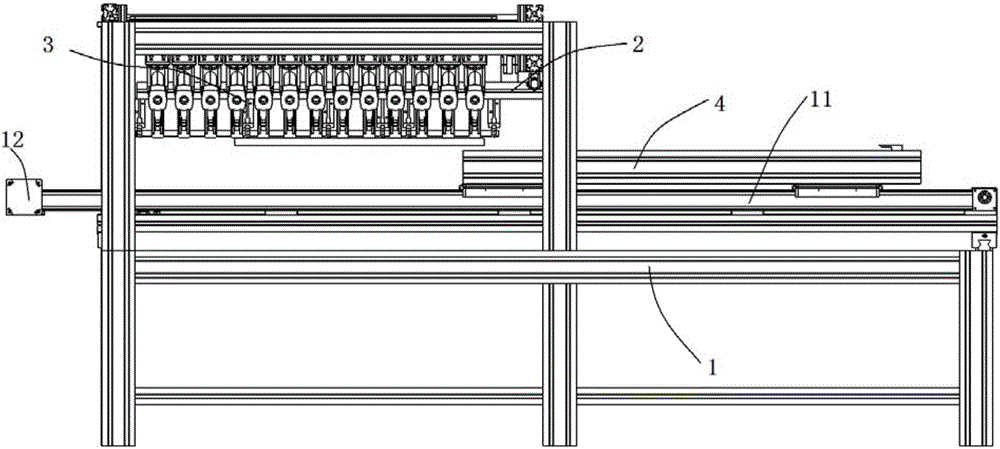

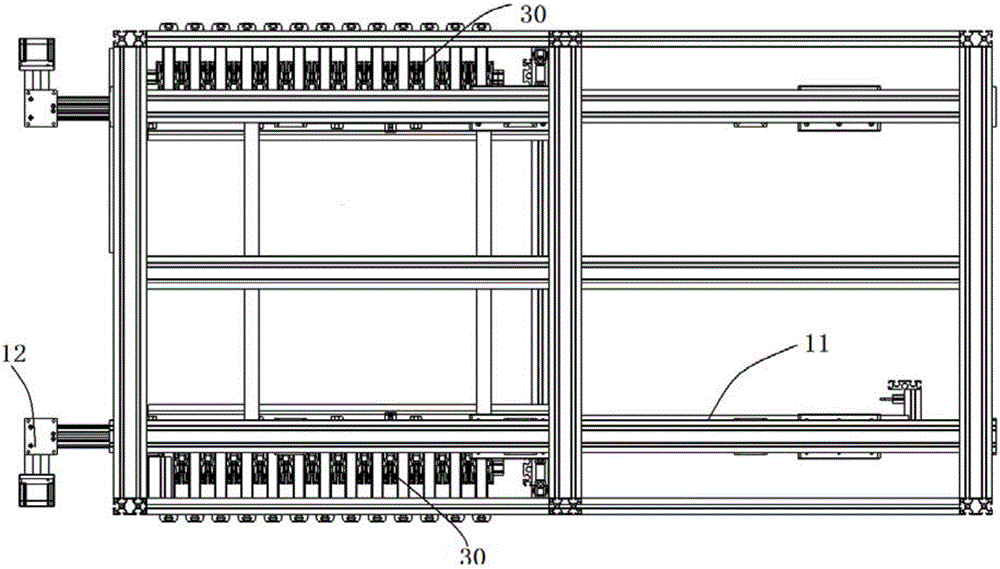

[0027] refer to Figure 1-3 As shown, the present embodiment discloses a canvas nailing device, which includes a frame 1, a moving track 11 is arranged on the top end surface of the above-mentioned frame 1, and the power source of the moving track 11 is a stepping motor 12, and the above-mentioned The stepping motor 12 drives the above-mentioned moving track 11 to push the canvas 5 and the picture frame 4 to move.

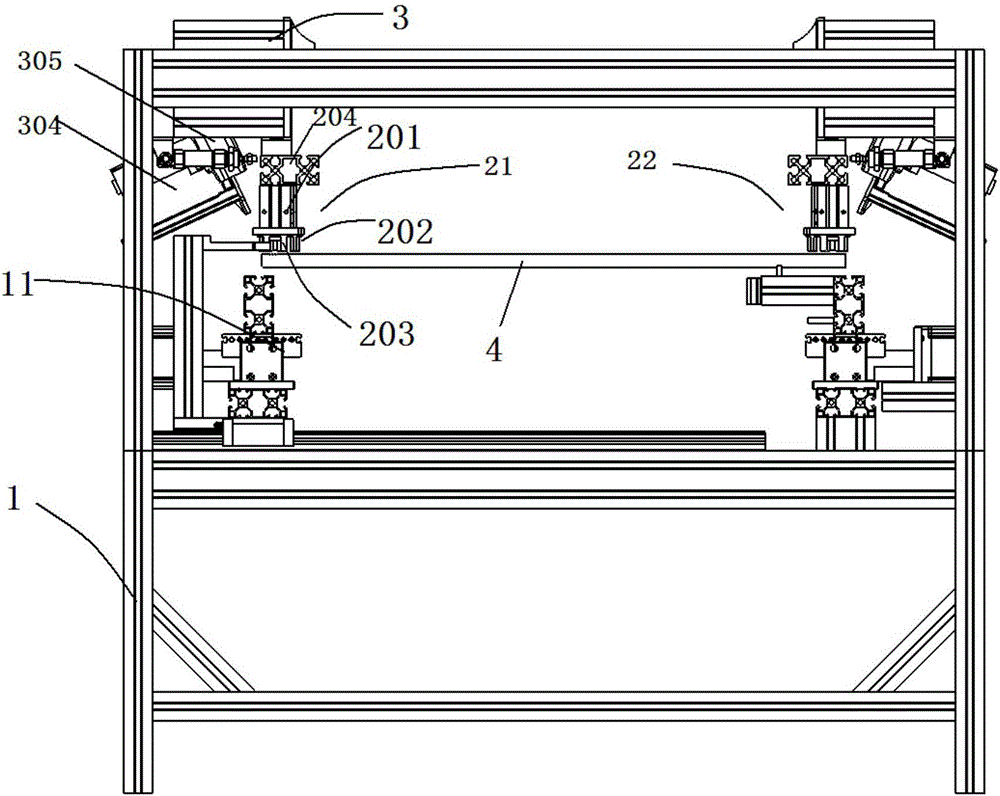

[0028] The above-mentioned frame 1 is also provided with a clamping and pushing device 2 and a nailing device 3, and the above-mentioned clamping and pushing device 2 and the nailing device 3 are arranged above the above-mentioned moving track 11, and the above-mentioned clamping and pushing device 2 wraps the edge of the canvas 5 to the On the picture frame 4 , the above-mentioned staple device 3 binds the canvas 5 to the picture frame 4 .

[0029] Such as figure 2 and Figure 4 As shown in , the above-mentioned clamping and pushing device 2 includes: a first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com