Mechanical type automatic equipment for clearing inner cavity of casting steel mold of cement telegraph pole

An automatic cleaning technology for cement utility poles, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of unsatisfactory cleaning effect, occupying operating space, and low work efficiency, so as to improve the speed of cleaning dirt, simple equipment structure, In addition to the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

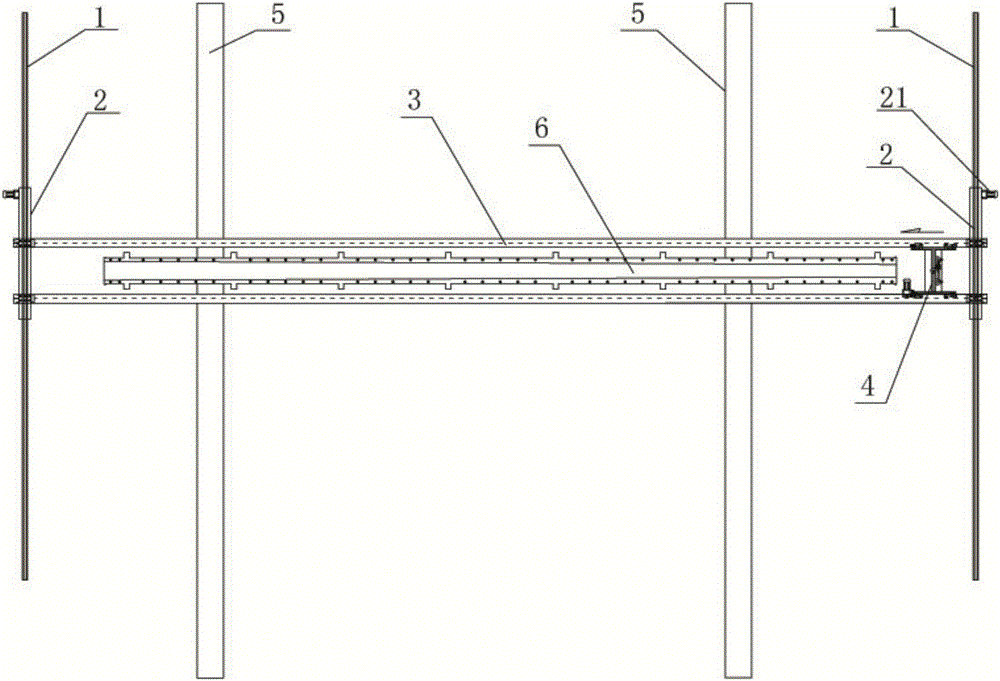

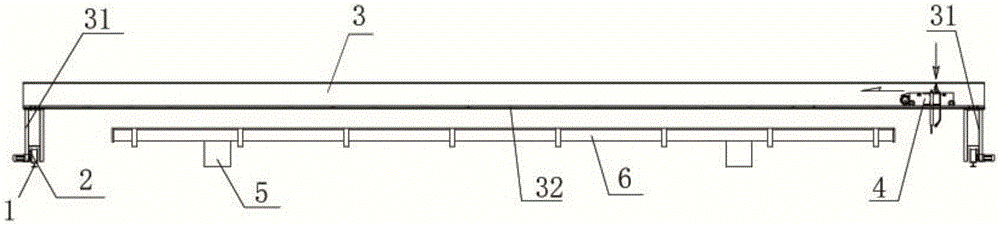

[0026] see figure 1 and figure 2 , the present invention is a kind of mechanical automatic cleaning equipment for the inner cavity of the cast steel mold of cement utility poles, comprising two parallel cart running tracks 1, a walking cart 2 respectively walking on each cart running track 1, connected to The traversing track 3 between the two walking carts 2 and the dirt cleaning trolley 4 walking on the traversing track 3, the traversing track 3 can move together with the two traveling carts 2, the traversing track 3 and the two carts Walking track 1 forms I-shaped.

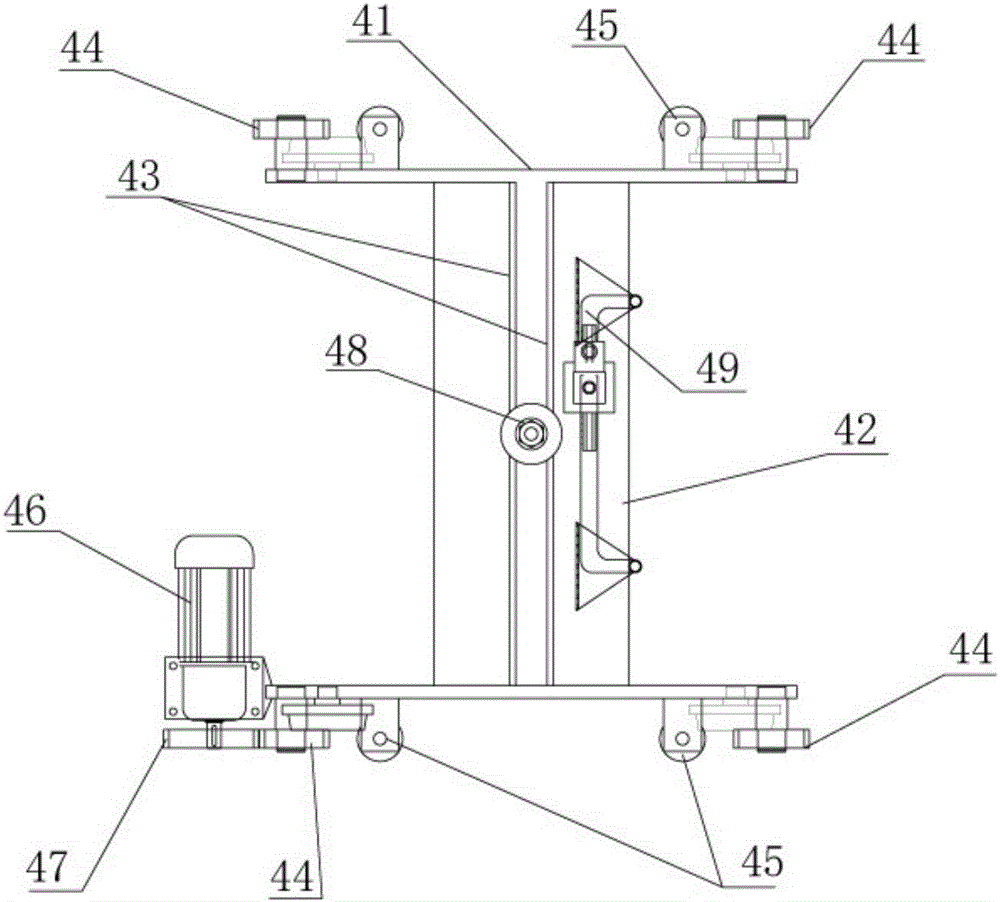

[0027] The traversing track 3 includes two left and right tracks with an I-shaped section. The dirt cleaning trolley 4 walks between the two tracks. The two ends of each track are respectively connected with a traversing track pillar 31, and the traversing track pillar 31 is supported on On the walking cart 2, the whole traversing track 3 can walk together with the two traveling carts 2, and the bottoms of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com