Hollow fiber composite nano-filtration membrane and preparation method thereof

A fiber composite, nanofiltration membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as limiting wide application, difficult to apply base membrane, etc., to achieve broad application prospects, high water flux , the effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Dissolve 5g of polyphenolic compound catechol and 10g of polyamino compound polyethyleneimine in 1L of water to obtain aqueous solution A; dissolve 0.5g of oxidant ammonium persulfate in 100mL of water to obtain aqueous solution B; ultrafilter No. 1 hollow fiber polysulfone The membrane (purchased from Hangzhou Haotian Membrane Technology Co., Ltd.) is immersed in the aqueous solution A (keep the interior of the fiber dry), and the aqueous solution B is driven into the interior of the hollow fiber by pressure and filled.

[0050] The hollow fiber membrane was left to stand at 40° C. for 30 minutes in such a state, and then washed with water and dried to obtain a hollow fiber composite nanofiltration membrane.

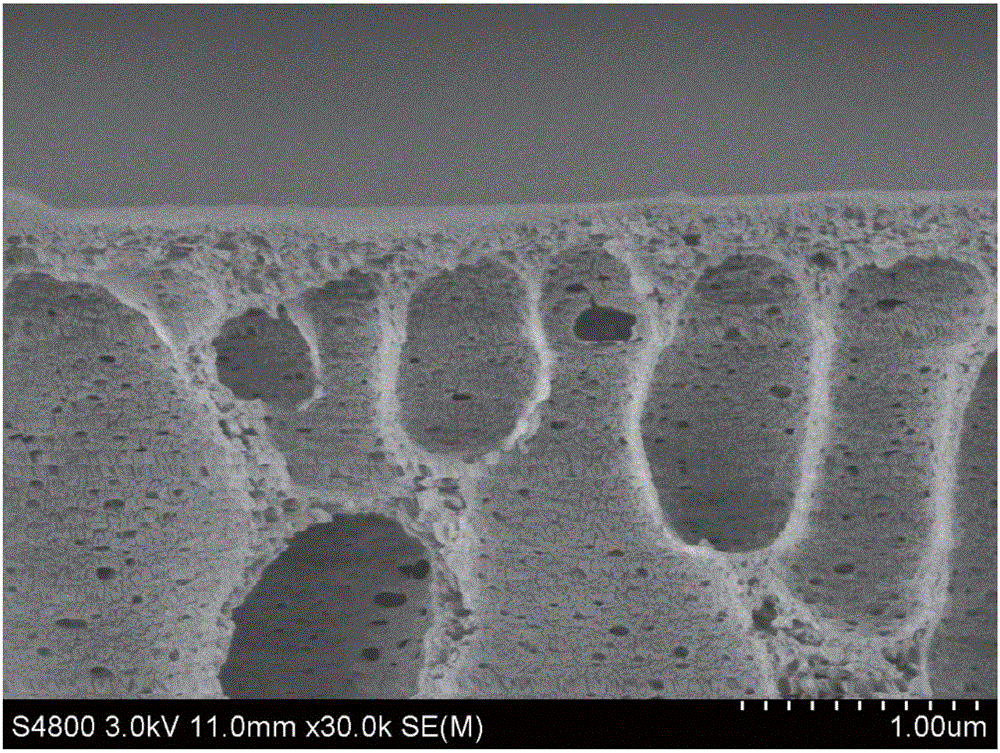

[0051] The scanning electron microscope image of the prepared hollow fiber composite nanofiltration membrane section is shown in figure 1 shown.

Embodiment 2~6

[0053] Adjust the concentration of polyphenol compound catechol to 0.1g / L, 1g / L, 10g / L, 20g / L, 100g / L, and the concentration of polyamino compound polyethyleneimine to 0.2g / L, 2g / L , 30g / L, 40g / L, 200g / L, the concentration of oxidant ammonium persulfate is 5g / L constant, all the other conditions are with embodiment 1.

Embodiment 7~10

[0060] Adjust the concentration of oxidant to 0.1g / L, 1g / L, 10g / L, 100g / L, the concentration of polyphenolic compound catechol is 5g / L, the concentration of polyamino compound polyethyleneimine is 10g / L, and other conditions With embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com