Butterfly type packaging semiconductor laser heat sink apparatus

A technology of semiconductor and laser, applied in the field of heat sink of butterfly packaged semiconductor laser, which can solve the problems of heavy weight and large volume, and achieve the effect of light weight, small volume and improved heat dissipation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

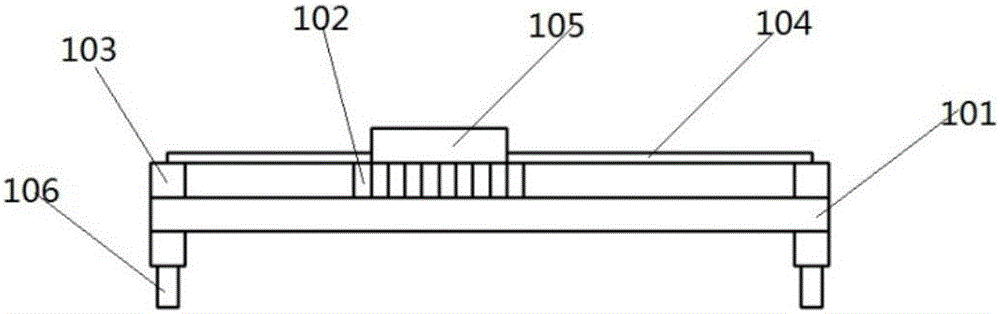

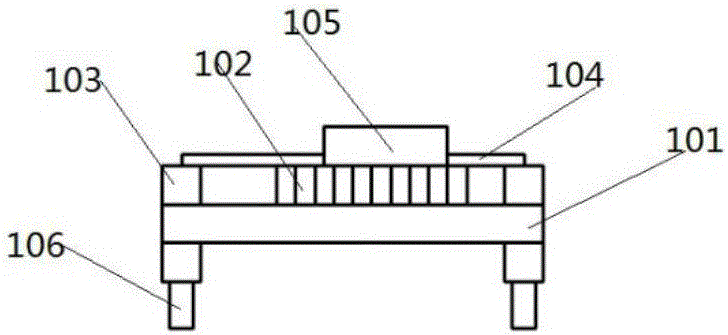

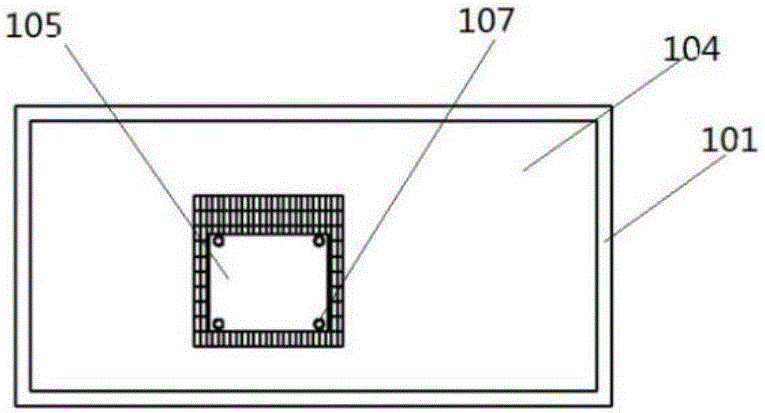

[0028] Figure 1a , Figure 1b , Figure 1c Shown is a schematic diagram of the structure of a butterfly package semiconductor laser heat sink device, where Figure 1a It is the front view of the butterfly package semiconductor laser heat sink device, Figure 1b It is the left view of the butterfly package semiconductor laser heat sink device, Figure 1c It is a top view of a butterfly package semiconductor laser heat sink device, which specifically includes: a heat sink base plate 101, a heat dissipation platform 102, a mounting hole 103, a PCB circuit board 104 and a butterfly package semiconductor laser 105. Among them, the shape of the heat sink base plate 101 is rectangular, and the material is light metal aluminum material with high thermal conductivity. The size of the heat sink base plate 101 matches the size of the drive control circuit PCB circuit board 104 of the butterfly package semiconductor laser; the mounting hole 103 is located At the four corners of the heat sink ...

Embodiment 2

[0037] Figure 2a , Figure 2b , Figure 2c It is a structural design drawing of the heat dissipation platform 102.

[0038] among them, Figure 2a Shown is a rectangular cooling platform. The cooling fins are comb-shaped, rectangular in shape and uniformly distributed in strips. In order to be suitable for different types of lasers, the cooling platform has a length of 25cm-30cm, a width of 13cm-20cm, and a height of 4cm-10cm. The spacing of the cooling fins of the cooling platform is 0.5cm-1.5cm, and the height is 3cm-8cm. The size of the cooling platform is smaller than the size of the heat sink bottom plate.

[0039] A common tunable semiconductor laser has a length of 24.410cm and a width of 12.700cm. The size of the heat dissipation platform is suitable for semiconductor lasers; the distance between the heat sinks is 0.5cm—1.5cm, the number of heat sinks of the heat dissipation platform is 15-60, and the heat sink height 3cm-8cm.

[0040] Figure 2b Shown is a rectangular coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com