Method for converting COMOS data to PDMS data in pipeline design

A pipeline design and data technology, applied in geometric CAD, electrical digital data processing, computer-aided design, etc., can solve the problems of increasing the designer's verification workload, reducing the quality of finished products, reducing work efficiency, etc., to improve design efficiency, Improve the quality of finished products and avoid errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

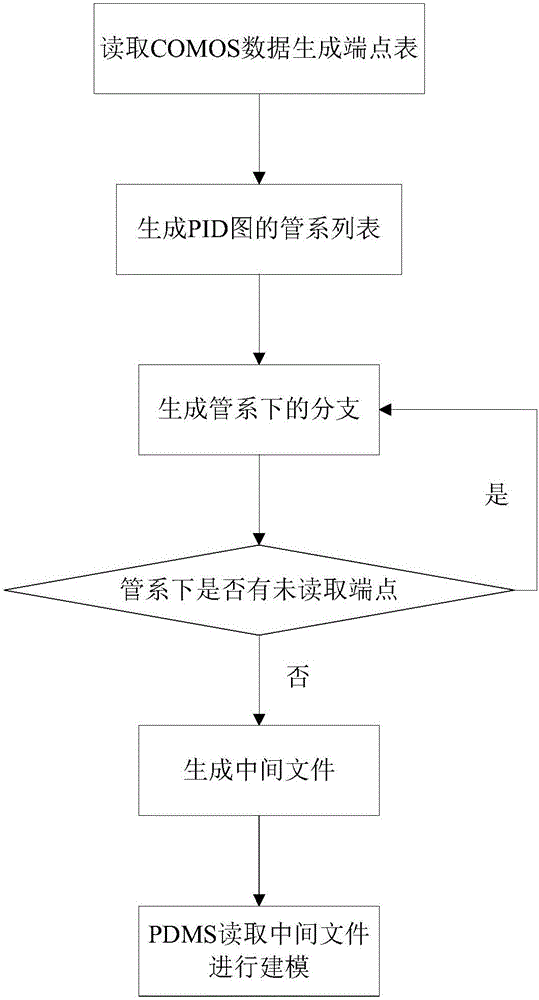

[0023] Such as figure 1 Shown in the pipeline design of the present invention COMOS data to the method for PDMS data conversion, the steps have:

[0024] A. Traversing all components (such as equipment interfaces, plugs, etc.) in the PID diagram of the COMOS software and the demarcation points of the components to generate an endpoint list.

[0025] B. Traverse all endpoints starting from the first endpoint in the endpoint list, and generate a pipe series list of the PID diagram. A piping system should include all pipes and components that are connected to it, and not include any pipes and components that are not connected to it; any end point should belong to a certain piping system in the piping series list, and record these Information about which piping system the endpoint belongs to.

[0026] C. Starting from the first piping system in the piping series list, starting from the starting key point of the piping system, reading along the pipeline to the next key point, gen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com