Coordinate measuring machine-strain joint measuring method for large-scale component

A strain measurement and measurement method technology, applied in the direction of electric/magnetic solid deformation measurement, measurement device, electromagnetic measurement device, etc., can solve the problem of inability to monitor the strain of a certain position in real time, and achieve the effect of convenient mobility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

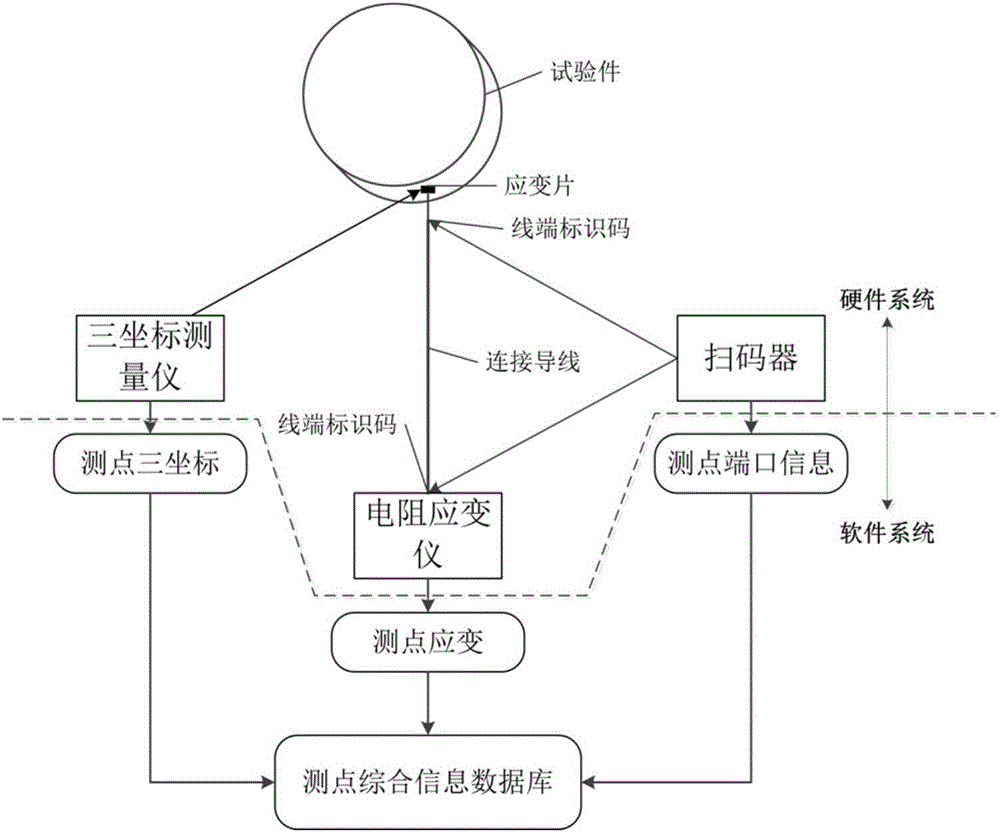

[0022] The present invention provides a three-coordinate-strain joint measurement method for large components, referring to figure 1 Among them, the part above the dotted line is the hardware equipment related to the present invention: test pieces, strain gauges, connecting wires, resistance strain gauges, code scanners, and three-coordinate measuring instruments. The part below the dotted line is the relevant software system. The main task of this part is to comprehensively process the information output by the hardware equipment and establish a comprehensive information database of measuring points. Specifically include the following steps:

[0023] The first step is to obtain the corresponding relationship between the static strain gauge port T and the measured strain value E

[0024] Attach multiple strain gauges to multiple strain measuring points A on the surface of the test piece as required, and each strain gauge corresponds to a wire with a wire end identification co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com