Oil return device and air-conditioning unit

An air-conditioning unit and oil return pipe technology, which is applied to compressors, refrigerators, refrigeration components, etc., can solve the problem that the buoyancy cannot adjust the liquid level of the oil-rich layer at the movable oil return port, and it is difficult to accurately locate the liquid level of the oil-rich layer with the lowest height. The hidden danger of running out of oil in the machine can avoid running out of oil, facilitate the production cost, and ensure reliable oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

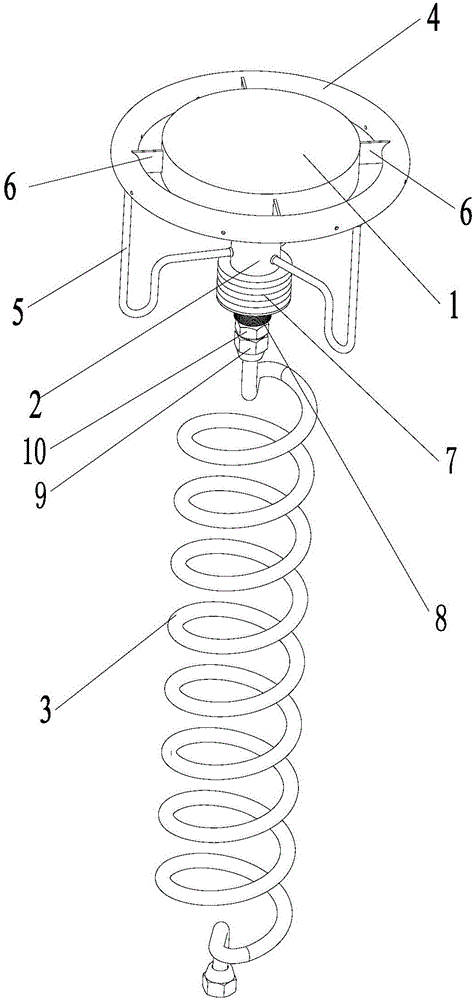

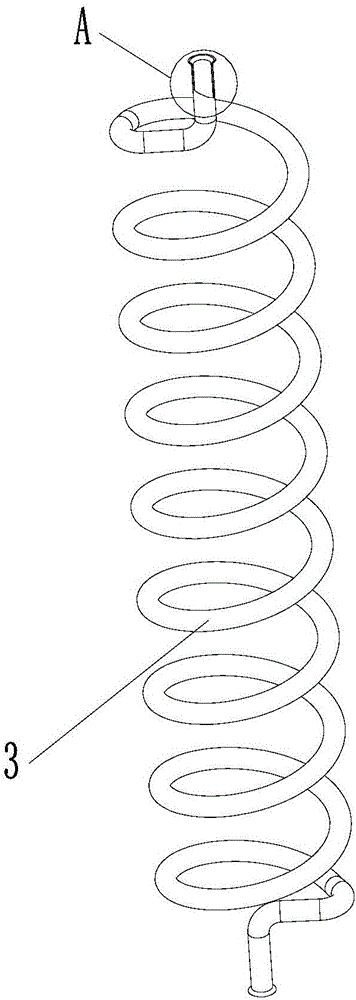

[0043] This preferred embodiment provides an oil return device, which is mainly but not limited to be used in refrigeration equipment such as air conditioners. see figure 1 The oil return device provided in this embodiment includes an oil return assembly provided with an oil return port 41, a float 1, a weight 2 and an oil return pipe 3, the oil return assembly is connected to the float 1, and the upper end of the weight 2 is connected to the float 1 or the oil return pipe. The oil assembly is connected, the lower end is connected with the upper end of the oil return pipe 3, the oil return port 41 is connected with the oil return pipe 3, and the lower end of the oil return pipe 3 is used to directly communicate with the oil outlet on the low-pressure circulating liquid storage barrel or indirectly communicate with other components, and the return The length of the oil pipe 3 in the vertical direction can be adjusted at least according to its force in the vertical direction.

...

Embodiment 2

[0058] This preferred embodiment provides an air-conditioning unit, and the air-conditioning unit is provided with the oil return device as described in the first preferred embodiment. The lower end of the oil return pipe 3 of the oil return device communicates directly with the oil outlet on the low-pressure circulating liquid storage barrel 11 or communicates indirectly through other components.

[0059] The oil return device can be installed in any way, please refer to Figure 13 and Figure 14 , preferably, a flange cover 12 is provided on the flange of the low-pressure circulating liquid storage barrel 11 of the air-conditioning unit, and a double joint 13 is fixedly connected to the oil outlet of the flange cover 12, and the lower end of the oil return pipe 3 of the oil return device passes through the connecting pipe Nut 14, joint 15 are tightened on the double joint 13.

[0060] The air-conditioning unit provided in this embodiment adopts the above-mentioned oil retu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com