An adjustable constant pressure air intake device for rotary engine

A technology of rotary engine and air intake device, which is applied in the direction of combustion engine, engine control, machine/engine, etc. It can solve the problems of lack of constant pressure air intake device, high residual exhaust gas coefficient, and unadjustable intake pressure, etc. Simple and efficient, fast and timely adjustment, stable pressure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

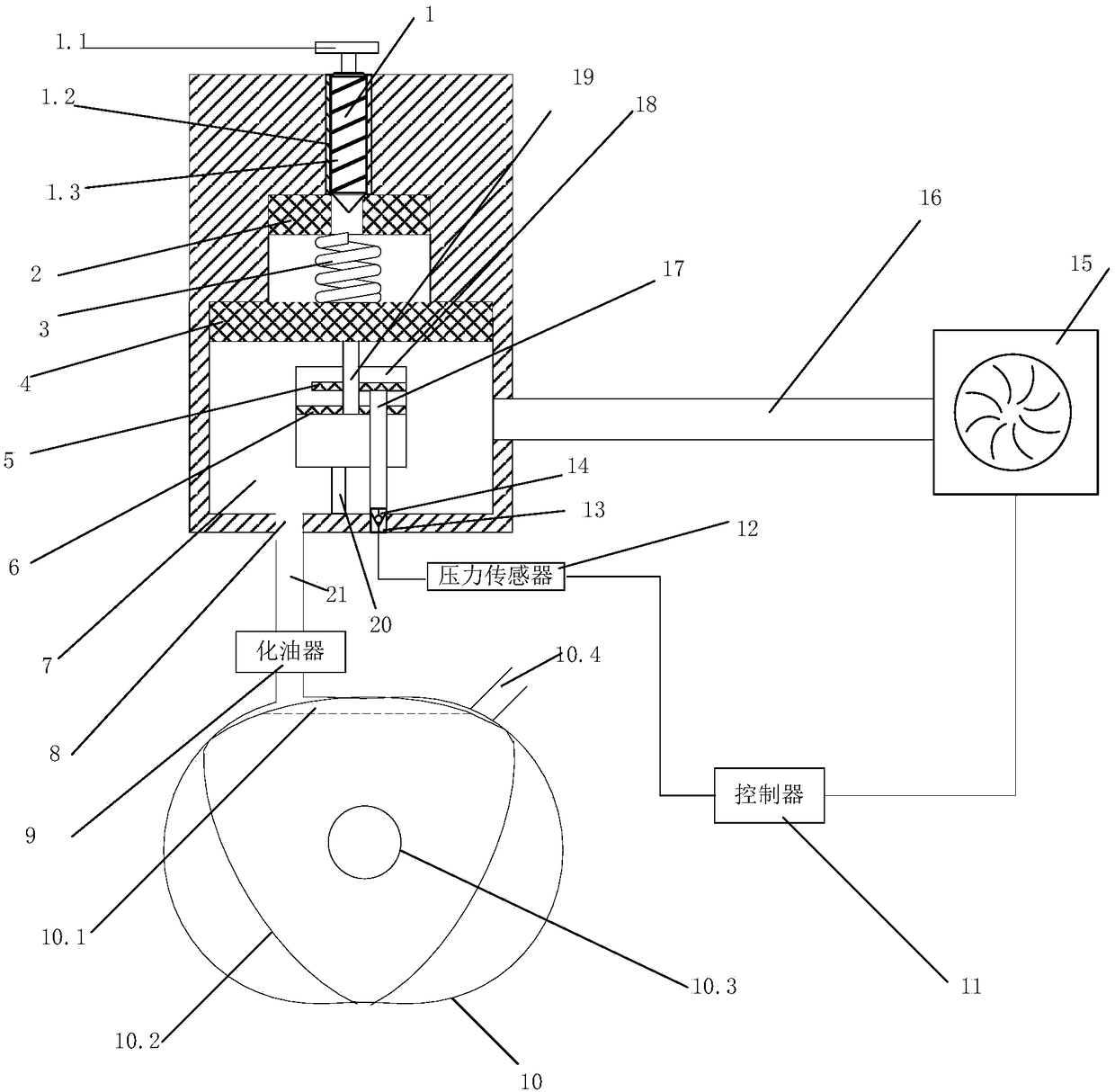

[0022] Such as figure 1 As shown, the embodiment of an adjustable constant pressure air intake device for a rotary engine disclosed in this embodiment is as follows figure 1 shown. The pressure gauge 1.1 and the remaining screw 1.2 are fixed together. The screw 1.2 can be screwed up and down in the thread groove 1.3. The screw 1.2 is on the top of the first plunger 2. The first plunger 2 is connected with the upper end of the spring 3. The lower end of the spring 3 is connected with the second The two plungers 4 are connected, the second plunger 4 can move up and down in the first working chamber 7, the second plunger 4 is in smooth contact with the surface of the chamber, and the lower end of the second plunger 4 is connected with the first column Plug rod 19, the first plunger rod 19 is integrated with the fourth plunger 6, the first plunger rod 19 passes through the second working chamber 18, the third plunger 5, the fourth plunger 6, the first plunger rod 19. The third p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com