Modularized assembly type steel structure house building system

A prefabricated, steel structure technology, applied in the direction of construction, building structure, etc., can solve the problems that affect the safety performance of buildings, the quality of welding seams is not suitable for control, and the construction speed is slow, so as to reduce the overall project cost and engineering accidents or errors Occurrence probability, reduction of on-site construction period and total construction period, construction efficiency and construction quality improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

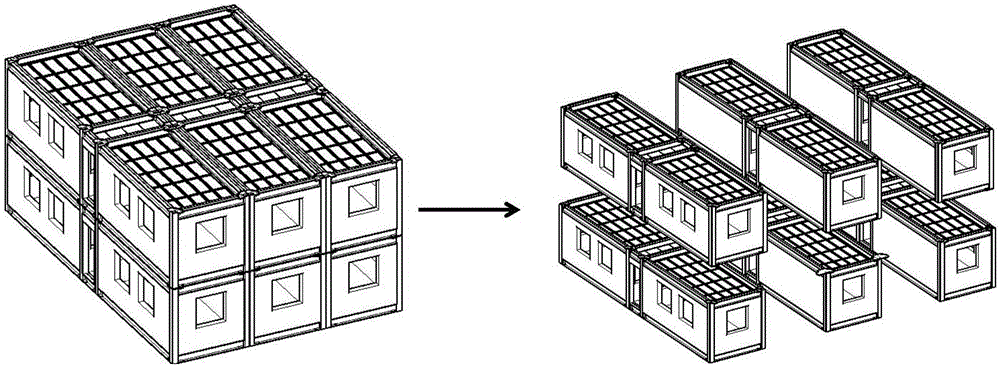

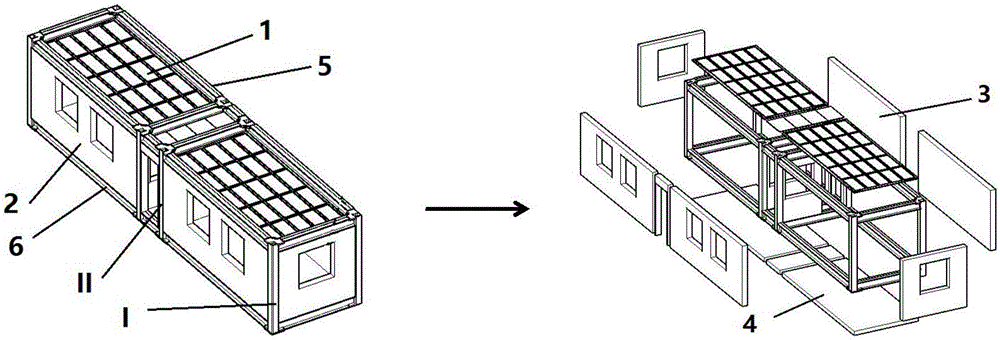

[0034] Attached below Figure 1-9 The present invention is described in detail:

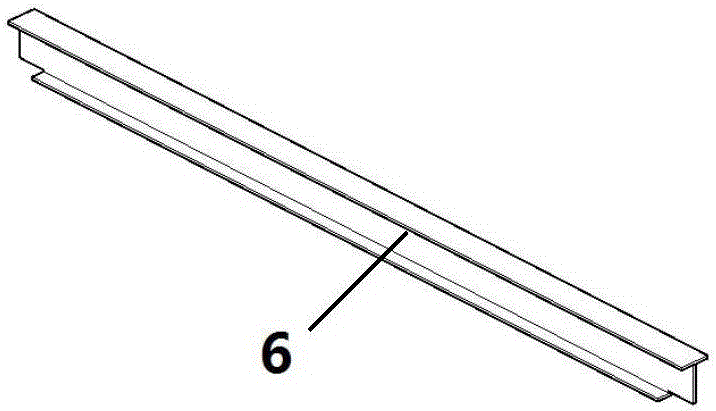

[0035] The modular prefabricated steel structure building system includes prefabricated suite modules and connecting parts, and is characterized in that: the prefabricated prefabricated suite modules are completed in factory construction; the prefabricated suite modules include beams, columns, floor slabs and The structure and equipment added therein according to the project requirements; at the construction site, the suite units can be connected by means of connectors;

[0036] The connecting parts include: high-strength bolts, filling parts and decorative parts installed at the holes for module connection and the joints of the outer wall or cast-in-place filling parts for installation operations, water supply and drainage pipes and water supply and drainage for connection between modules Pipe connection parts, heating pipes and heating pipe connection parts for connection between modules, wire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com