Clamp spring conveying press-in structure

A circlip and indenter technology, applied in the field of circlip handling and pressing into the structure, can solve the problems of low installation efficiency, low qualified rate of finished products, low production capacity, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

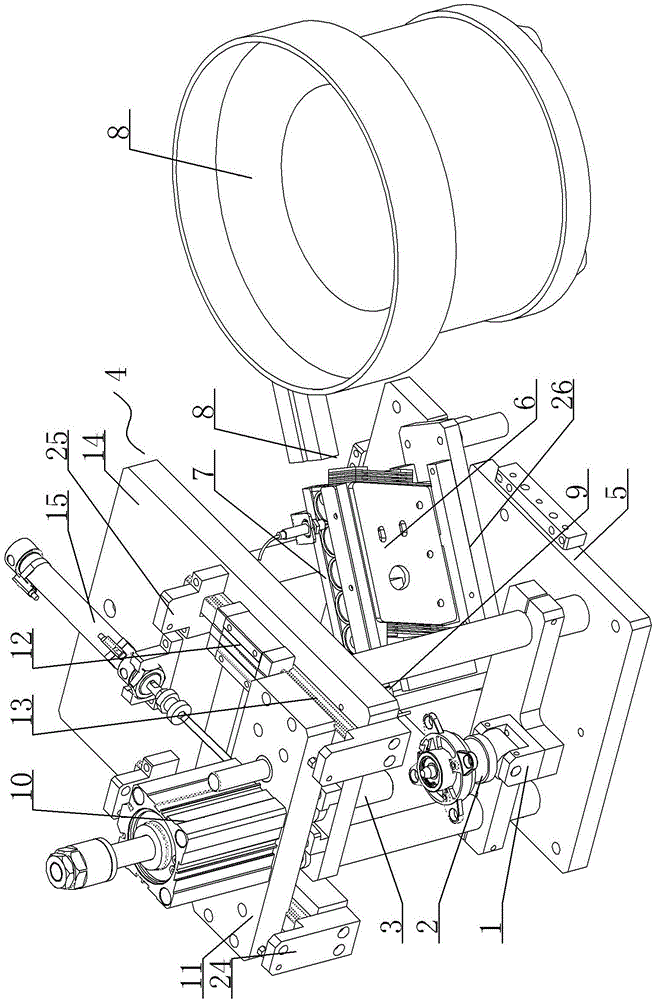

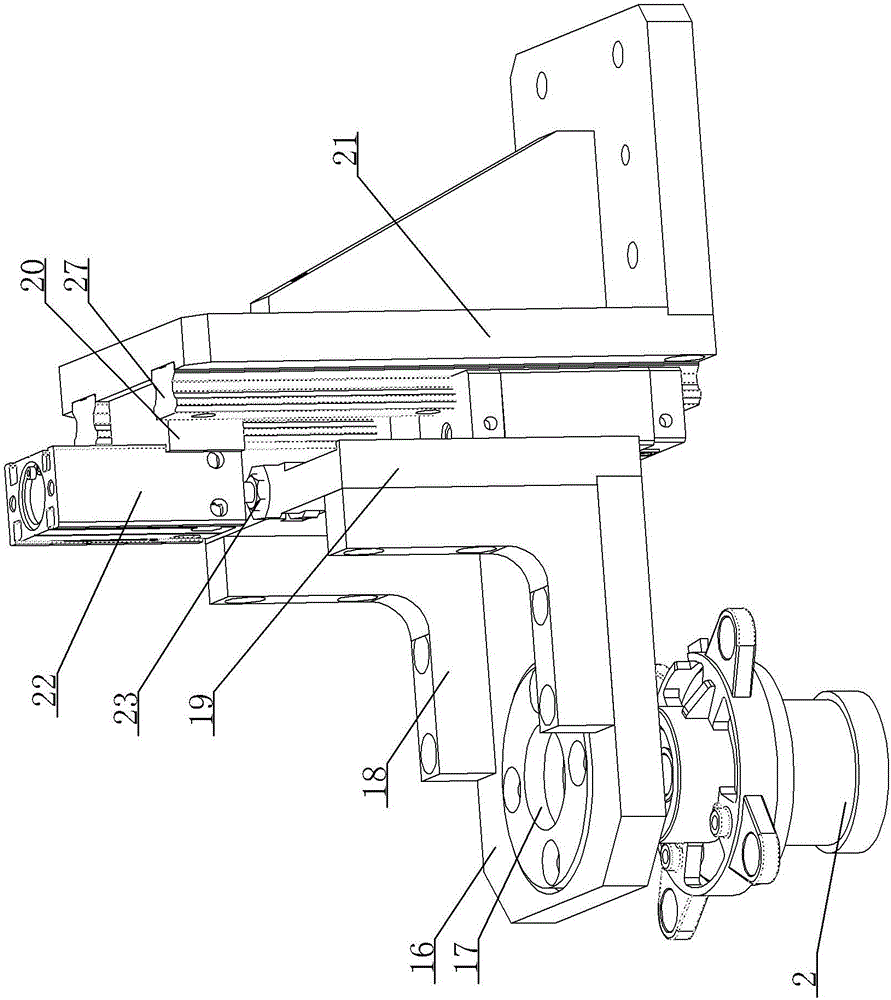

[0015] A kind of circlip handling press-in structure, see figure 1 , figure 2 : It includes a jig tray 1, a jig 2 is fixed on the jig tray 1, the jig 2 is used for positioning the bearing, an indenter 3 is arranged above the jig 2, and a magnet is built in the indenter 3, and the jig tray 1 Supported on the bottom plate 5 of the bracket 4, the bottom plate 5 of the bracket 4 is provided with a direct vibration machine 6, and the upper end surface of the direct vibration machine 6 is fixed with a linearly arranged circlip flow channel 7, and the input end of the circlip flow channel 7 Connect the discharge port of the feeding vibrating plate 8, there are circlips stacked in the feeding vibrating plate 8, the product arrival sensor 9 is arranged towards the output end of the circlip flow channel 7, the upper part of the pressure head 3 is fixed on the circlip and pressed into The piston ends of the upper and lower cylinders 10 are pressed into the bases of the upper and lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com