Greenhouse for planting vegetables

A technology for greenhouses and vegetables, applied in the fields of botanical equipment and methods, horticulture, greenhouse cultivation, etc., can solve the problems of inconvenient cleaning of fallen leaves or sundries, easy damage to thermal insulation films, affecting light transmittance, etc., to reduce the labor intensity of transportation, The effect of good ventilation and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

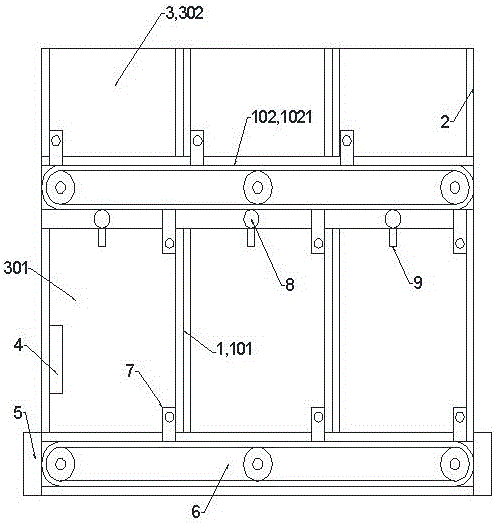

[0017] Such as figure 1 , 2 As shown in and 3, a vegetable planting greenhouse comprises a skeleton 1, an arc support frame 2 and a film cover 3, an arc support frame 2 is arranged above the skeleton 1, and the film cover 3 covers the frame 1 and the arc-shaped The outer side of the support frame 2; and the skeleton 1 includes a vertical skeleton 101 and a beam skeleton 102, and the film cover 3 includes a shed body side wall cover 301 and a shed body top cover 302; the beam skeleton 102 includes a beam skeleton A1021 and a beam Skeleton B1022, the crossbeam skeleton A1021 is arranged between the adjacent vertical skeletons 101 on one side of the shed body, the crossbeam skeleton B1022 is arranged perpendicular to the crossbeam skeleton A1021; and the film cover 3 is formed according to the vertical skeleton 101 and the crossbeam skeleton 102 The area of the shed is set in blocks; the shed is also provided with a control device 4 and a drive device 5, the control device 4 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com