Secondary battery and battery module

A secondary battery and electrode assembly technology, which is applied in the field of secondary batteries and battery modules, can solve problems such as battery explosion and poor air flow, and achieve the effects of preventing explosion, improving safety, and solving battery overcharge problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

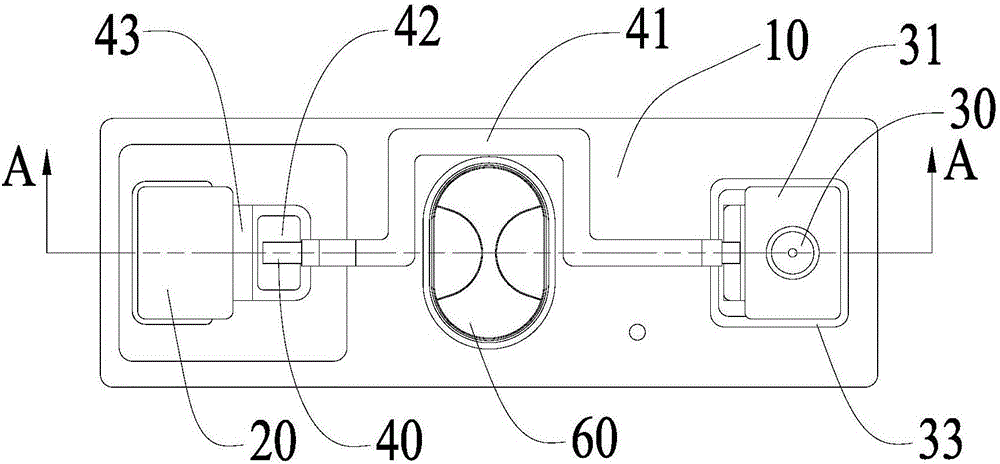

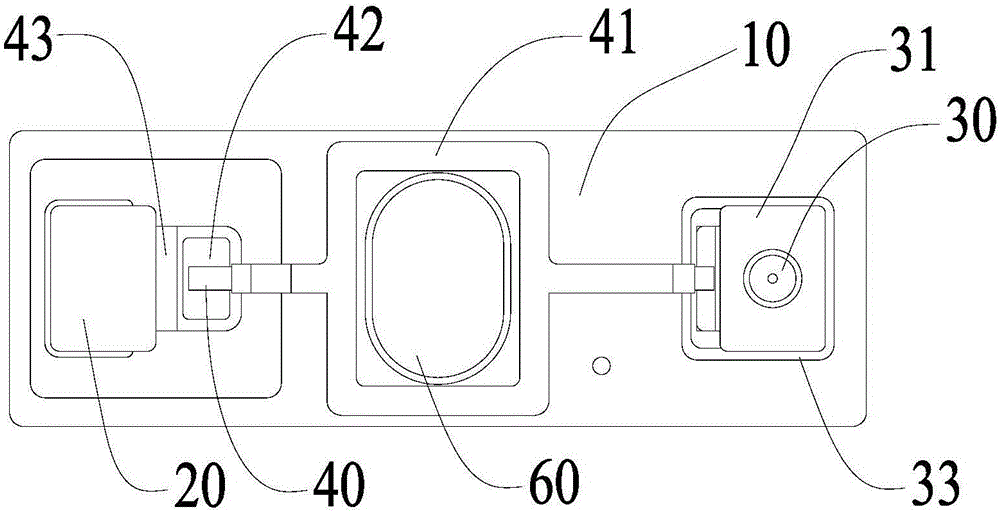

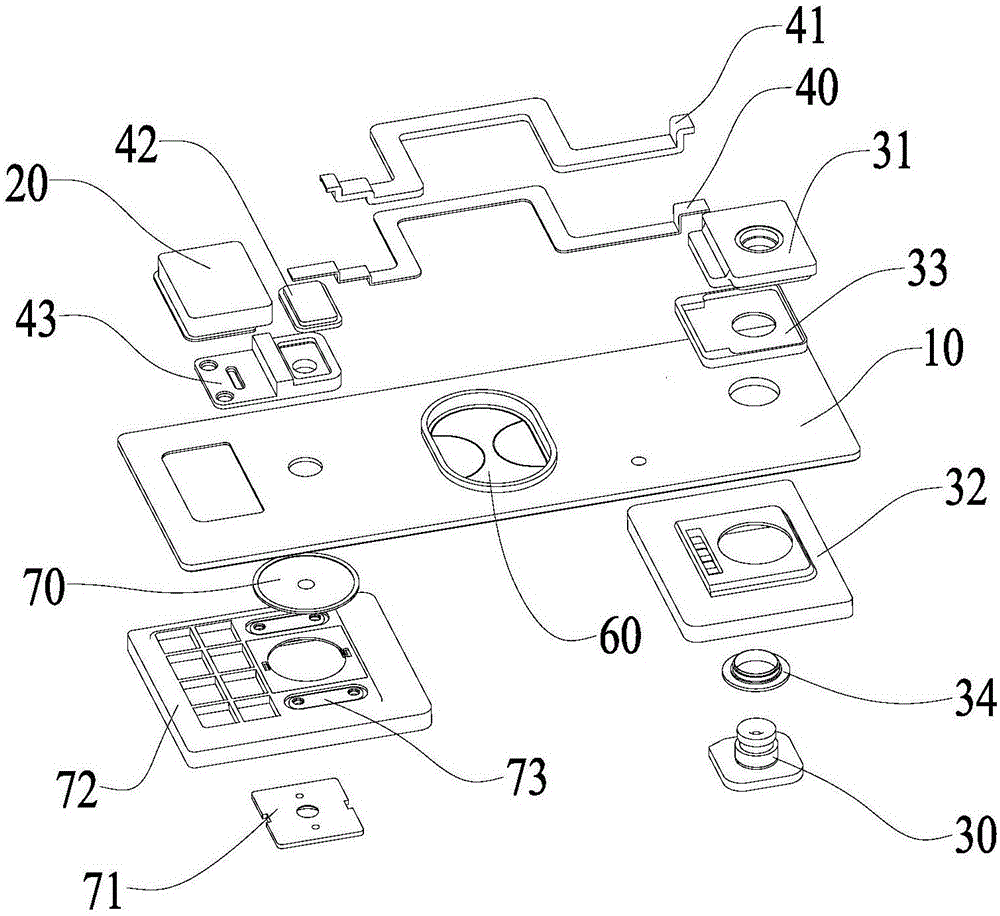

[0115] In the first embodiment, the flipping piece 70 is connected to the top cover piece 10, and the first terminal 20 is electrically connected to the top cover piece 10, specifically, as Figure 1-3 , 4, and 7, the top cover sheet 10 is provided with a first through hole, and the flip sheet 70 is attached to the top cover sheet 10 and seals the first through hole, so that the top cover sheet 10, the flip sheet 70 and the housing form a seal cavity. The first terminal 20 is electrically connected to the top cover sheet 10 , preferably the top cover sheet 10 may be provided with a fourth groove, and the first terminal 20 is inserted into the fourth groove; the second terminal 30 is electrically insulated from the top cover sheet 10 . The connecting piece 40 is electrically insulated from the top cover sheet 10 , and at least a part of the connecting piece 40 (the contact portion 401 when the contact portion 401 is provided) is opposite to the first through hole. In the norma...

no. 2 example

[0116] In the second embodiment, the turning piece 70 is attached to the first terminal 20, such as Figure 3a , 4a As shown, a first through hole is provided on the first terminal 20, and the flipping piece 70 seals the first through hole. At this time, when the connecting piece 40 is located on the side of the top cover sheet 10 away from the first pole piece, the top cover sheet 10 is provided with a second through hole, and the second through hole is opposite to the first through hole. In the normal state, the first pole piece is electrically connected to the first terminal 20 through the reversing piece 70; In the connected state, the flipped flip 70 is electrically connected to the connector 40 , so that the first terminal 20 is electrically connected to the second terminal 30 through the flip 70 , the connector 40 . When the secondary battery expands or compresses and when the top cover sheet 10 is welded to the housing, the resulting force will be applied to the top ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com