Multi-angle shooting support and system

A multi-angle, photographed technology, applied in the direction of the machine/stand, support machine, optics, etc., can solve the problems of a large number of digital cameras, high cost, inconsistency, etc., and achieve the effect of constant and consistent shooting performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] An embodiment of the present invention provides a multi-angle shooting bracket, including:

[0054] a base, a support arm and a connection part arranged between the base and the support arm;

[0055] The supporting arm can move relative to the base under the action of the connecting part;

[0056] The support arm is used to place at least one specified object, and the specified object is fixed on the support arm or can move along the support arm; the specified object includes an image acquisition device or an object to be photographed; the image acquisition device includes a camera or a microscope.

[0057] The multi-angle shooting support provided in this embodiment can make the specified object move along with the supporting arm, so that multiple images can be taken during the moving process. For example, when the specified object is a camera, the camera can shoot the object to be photographed from multiple angles during the movement, thereby obtaining multiple sets ...

Embodiment 2

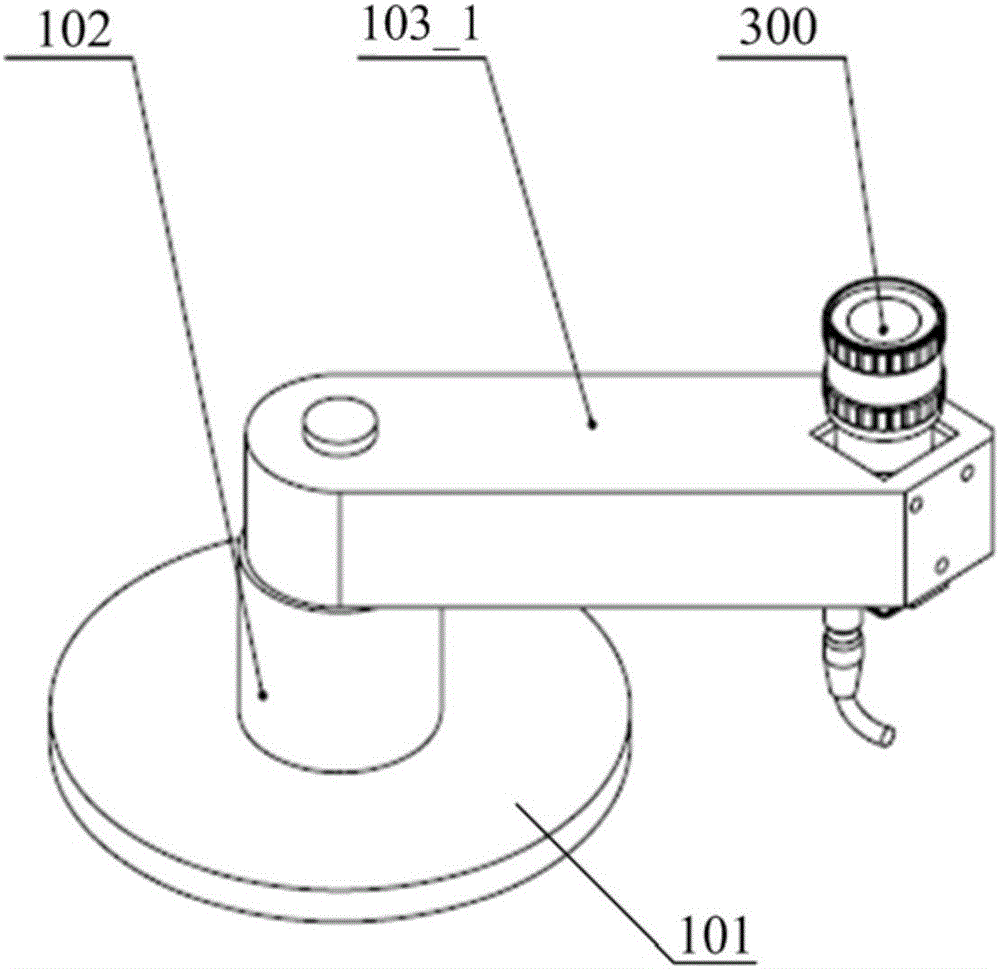

[0079] For ease of understanding, this embodiment provides a specific implementation example of the rotating multi-angle shooting bracket listed in Embodiment 1 in Mode 1. Here, the specified object is a camera in an image acquisition device as an example for illustration. see figure 1 The shown structural diagram of a multi-angle shooting bracket specifically includes a flat base 101, a rotating shaft 102 and a rotating support arm 103_1, and one end of the rotating support arm 103_1 is provided with a card position for fixing the camera. also, figure 1 The camera 300 is also shown in , and the camera 300 can be fixed on the card position of the rotating support arm 103_1.

[0080] Wherein, the flat base 101 is shown in a disc shape, and other shapes may also be used in specific applications, as long as the rotating shaft 102 can be stably fixed.

[0081] The rotating support arm 103_1 can make a circular motion with the rotation of the rotating shaft 102, thereby driving t...

Embodiment 3

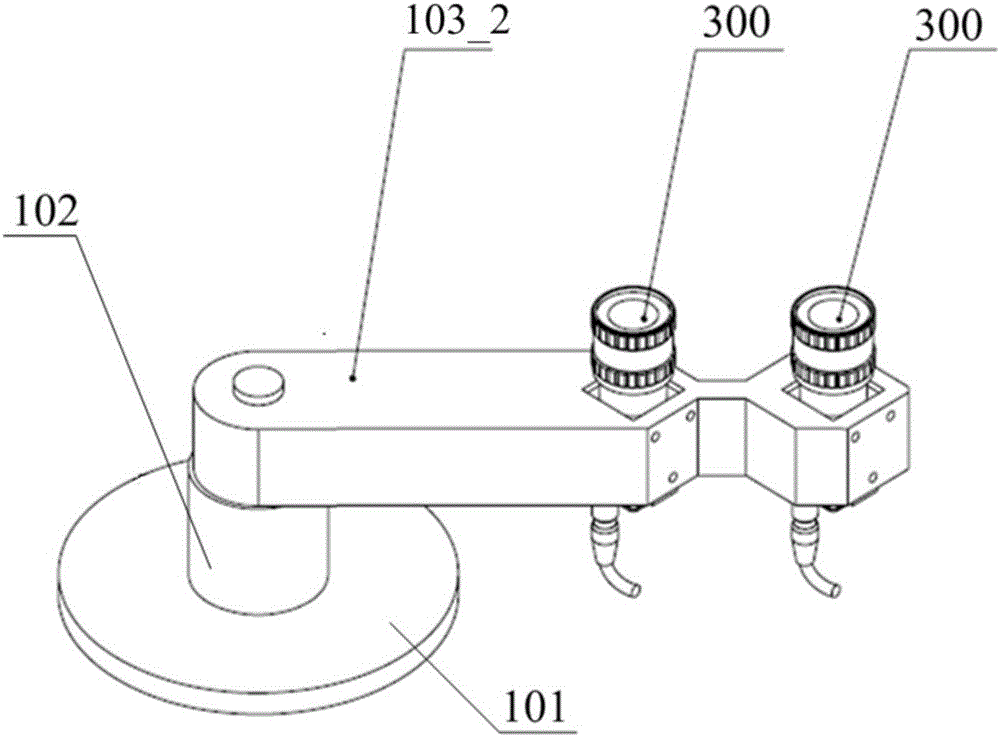

[0084] Corresponding to the second embodiment, the embodiment of the present invention provides another multi-angle shooting bracket, see image 3 A structural schematic diagram of a multi-angle shooting bracket shown, image 3 It also includes a flat base 101, a rotating shaft 102 and a rotating support arm 103_2, image 3 and figure 2 The difference is that one end of the rotating support arm 103_2 is provided with two card slots for fixing the camera, image 3 Also shown in the figure are two cameras 300 fixed on two card slots.

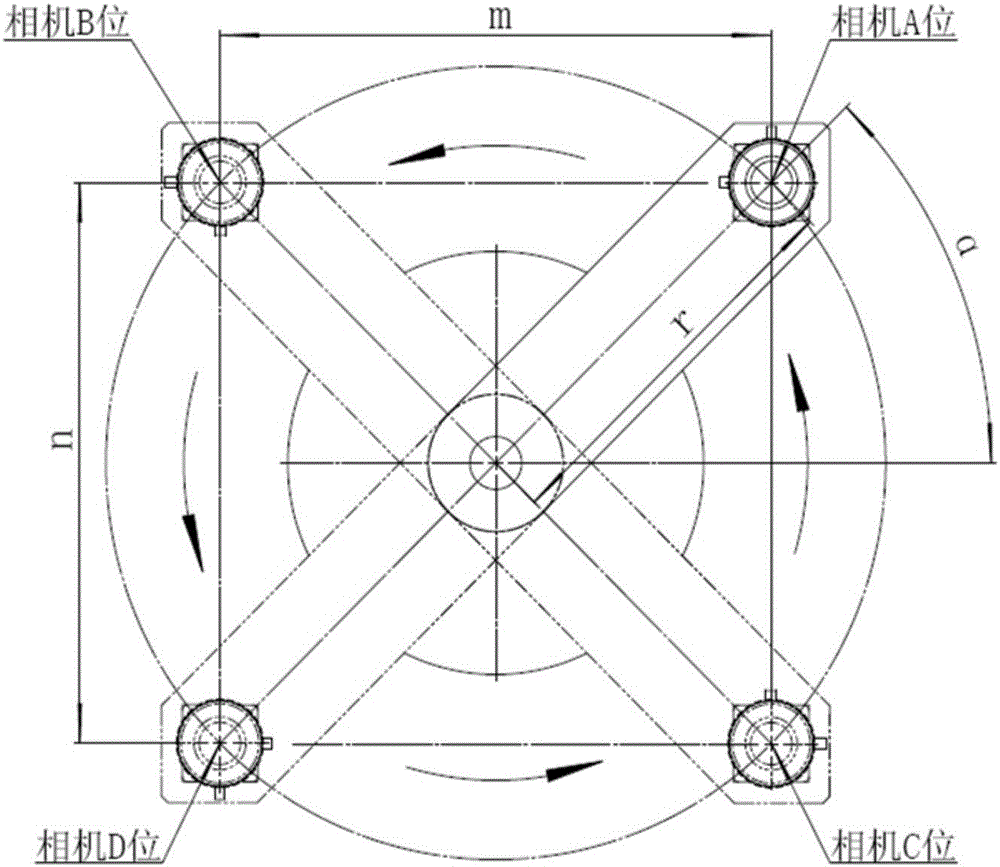

[0085] The rotating support arm 103_2 can drive the two cameras 300 to rotate along with the rotation of the rotating shaft 102. For details, see Figure 4 A schematic diagram of the shooting process of a camera is shown. The rotating support arm rotates one circle, and the camera on the outside (distance R from the rotation axis) is divided into camera points on the circumference (also called camera A positions, the same below), Camera point...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com