Binary power generation system and binary power generation method

A power generation system, double-cycle technology, applied in the direction of machines/engines, steam engine devices, mechanical equipment, etc., can solve the problems of reduced efficiency, insufficient operating efficiency of the expander, etc., and achieve the effect of high-efficiency Rankine cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in description of drawings, the same code|symbol is attached|subjected to the same element, and overlapping description is abbreviate|omitted.

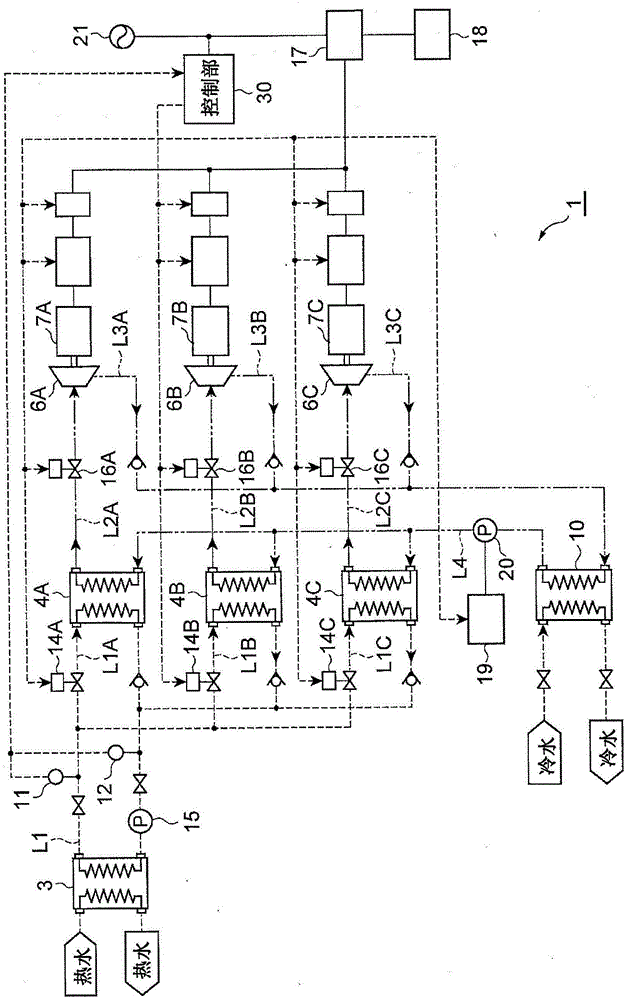

[0017] First, refer to figure 1 The two-cycle power generation system 1 of this embodiment will be described. figure 1 In , the solid line represents the electric circuit, and the dotted line represents the hot water circuit. The two-dot dash line indicates the circuit of the working medium. A dotted line connected to the control unit 30 represents a control loop.

[0018] Such as figure 1 As shown, the dual-cycle power generation system 1 is a power generation system that heats and evaporates a working medium with a relatively low boiling point using a relatively low temperature (for example, about 80-90° C.) heat source, and uses the steam to generate electricity. As the heat source, any heat source can be use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com