Separation and purification technology of 2-methylnaphthalene

A technology of methyl naphthalene and mixed methyl naphthalene is applied in the directions of crystallization purification/separation, distillation purification/separation, hydrocarbon purification/separation, etc., and can solve the problems of difficulty in separation, difficulty in obtaining starting materials, and increased investment in equipment, etc. achieve low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

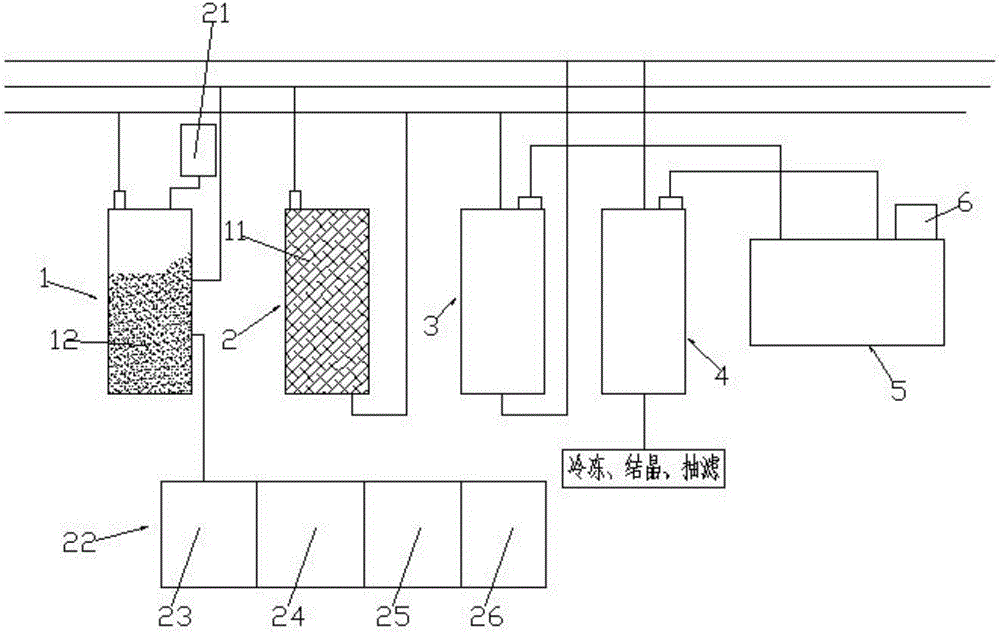

Image

Examples

Embodiment 2

[0033] Embodiment two, between step three and step four of embodiment, increase a pre-negative pressure distillation process, flow the liquid material after step three in embodiment one into negative pressure distillation tower 3; From negative pressure distillation tower 3. The mixed methylnaphthalene is extracted from the bottom of the tower, and the 2-methylnaphthalene fraction is extracted from the top of the negative pressure distillation tower; the temperature at the top of the tower is 180°C; the vacuum degree of the pressure at the top of the tower is 95%, and the temperature at the top of the tower is 170°C. The reflux ratio is 10; the output content is not less than 98% of 2-methylnaphthalene;

[0034] The mixed methylnaphthalene extracted in the above steps is frozen at -20°C, crystallized and suction filtered, and 2-methylnaphthalene with a purity greater than 99.8% is extracted therefrom. The extracted 2-methylnaphthalene enters the catalyst 5 to allow trace compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com