SSZ -13 molecular sieve preparing method

A molecular sieve and crystal growth technology, applied in the field of molecular sieves, can solve the problems of uneven particle size, affecting the catalytic performance of molecular sieves, poor crystal form of SSZ-13 molecular sieves, etc., to simplify the production process, avoid the ammonium exchange process, and facilitate industrial operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] A preparation method of SSZ-13 molecular sieve, comprising the following steps:

[0033] ①Mix N,N,N-trimethyladamantane ammonium hydroxide and crystal growth agent evenly, put them into the autoclave, then add silicon source, aluminum source and water to it in sequence, and get the initial gel after stirring; N,N,N-trimethyladamantylammonium hydroxide in the initial gel: crystal growth agent: SiO 2 :Al 2 o 3 :H 2 The molar ratio of O is 0.06-0.25:0.00085-0.025:1:0.017-0.063:20-40; the crystal growth agent is piperazine;

[0034] ② Crystallize the initial gel obtained in step ① at 155-175°C for 17-72 hours to obtain a crystallized product;

[0035] ③Centrifuge the crystallized product obtained in step ② to obtain a filter cake and filtrate, wash the obtained filter cake with deionized water until the pH reaches 7~8, and then dry it at 100~120°C for 10~13 hours to obtain SSZ- 13 Molecular sieves.

[0036] Preferably, the silicon source is silica sol, white carbon bl...

Embodiment 1

[0049] ①Mix 31.3kg N,N,N-trimethyladamantane ammonium hydroxide (SDA 25wt%) and 0.01kg crystal growth agent anhydrous piperazine (100wt%) evenly, add to the autoclave, and then add 13.3kg aluminum sulfate solution (Al 2 o 3 7.16wt%), 35.6kg silica sol (SiO 2 25wt% ) and 71.1kg of water, and the initial gel was obtained after stirring; ②The initial gel obtained in step ① was crystallized at 155°C for 72 hours to obtain a crystallized product;

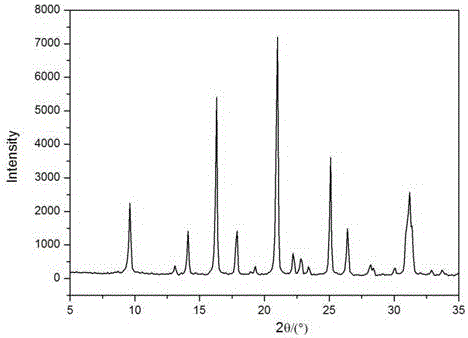

[0050] ③ Centrifuge the crystallized product obtained in step ② to obtain a filter cake and filtrate, wash the obtained filter cake with deionized water until the pH reaches 7, and then dry it at 100°C for 13 hours to obtain SSZ-13 molecular sieve, wherein the sodium content Take Na 2 O% meter, its numerical range is 0.01%, gained SSZ-13 molecular sieve is through X-ray diffraction (XRD) inspection and is pure phase SSZ-13 molecular sieve, and the X-ray diffraction pattern of sample sees attached figure 1 Shown, the scanning electron...

Embodiment 2

[0052] ①Mix 12.1kg N,N,N-trimethyladamantyl ammonium hydroxide (SDA 25wt%) and 0.03kg crystal growth agent anhydrous piperazine (100wt%) evenly, add to the autoclave, and then add 0.56kg pseudoboehmite (Al 2 o 3 66.1wt%), 19.2kg ethyl orthosilicate (SiO 2 25wt% ) and 120.2kg of water, the initial gel was obtained after stirring;

[0053] ② Crystallize the initial gel obtained in step ① at 175°C for 17 hours to obtain a crystallized product;

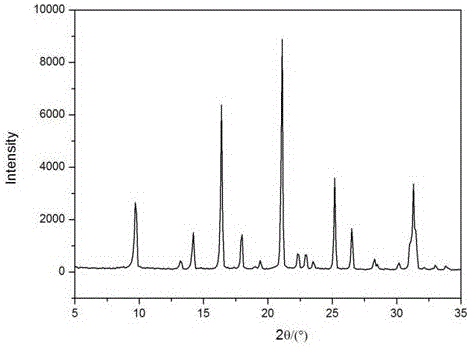

[0054] ③ Centrifuge the crystallized product obtained in step ② to obtain a filter cake and filtrate, wash the obtained filter cake with deionized water until the pH reaches 8, and then dry it at 130°C for 10 hours to obtain SSZ-13 molecular sieve, wherein the sodium content Take Na 2 O% meter, its numerical range is 0.02%, gained SSZ-13 molecular sieve is through X-ray diffraction (XRD) inspection and is pure phase SSZ-13 molecular sieve, and the X-ray diffraction pattern of sample sees attached figure 2 Shown, the scanning electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com