Plane flat-pressing type high-load-bearing bearing chain

A chain and bearing technology, applied in the field of chains, can solve the problems that cannot meet the needs of high-precision transfer of ultra-high-weight objects in sheet-fed offset printing machines, affect the accuracy of chain transmission, increase transmission friction, etc., and achieve small resistance, The effect of ingenious structure and strong load-bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

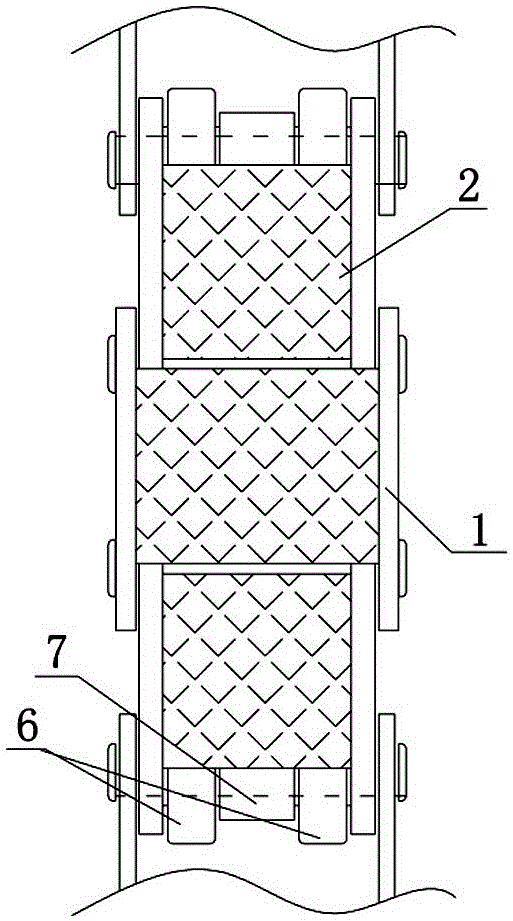

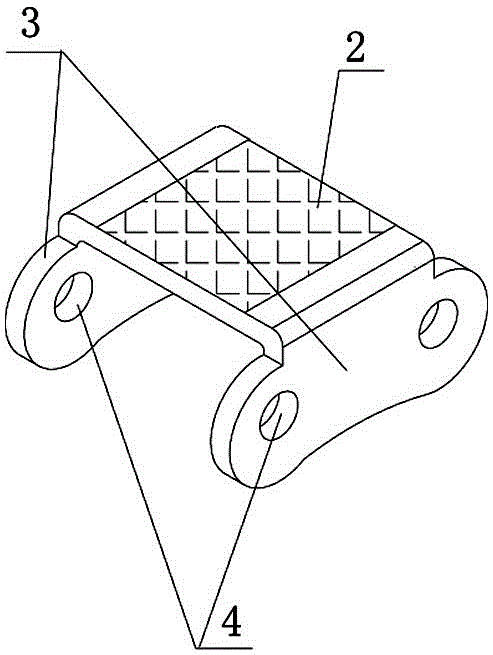

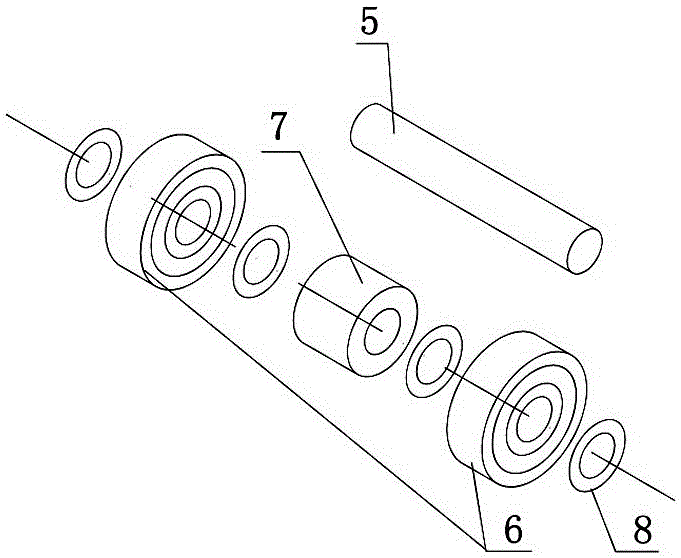

[0015] Such as figure 1 , 2 As shown in , 3, the plane flat pressure high load bearing chain of the present invention includes a chain body formed by a plurality of chain units hinged through the connecting plate 1, the chain unit includes a molded door-shaped inner buckle plate, and the door-shaped The upper top surface 2 of the inner gusset is the load-bearing conveying surface, and the front and rear ends of the vertical plates 3 on both sides of the door-type inner gusset are symmetrically provided with pin holes 4; The pin shaft 5 between the pin holes is covered with left and right load bearings 6, between the left and right load bearings, a sprocket rotation bushing 7 is arranged, and spacers 8 are arranged on both sides of the left and right load bearings 5.

[0016] In order to ensure the flexibility of the chain, the front and rear ends of the vertical plates 3 on both sides of the door-shaped inner gusset are in a semicircular structure, and the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com