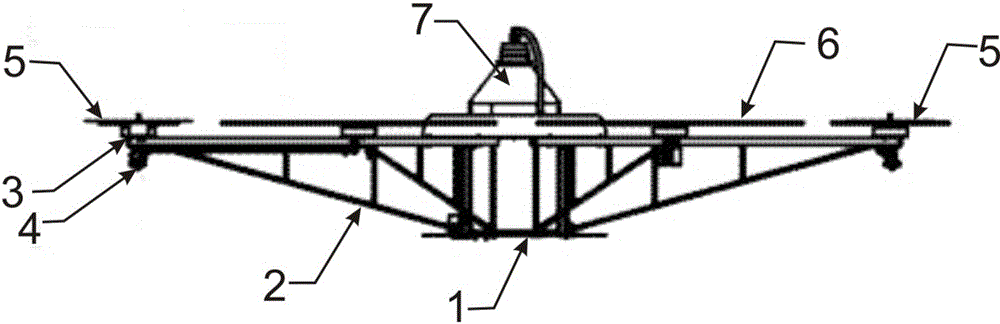

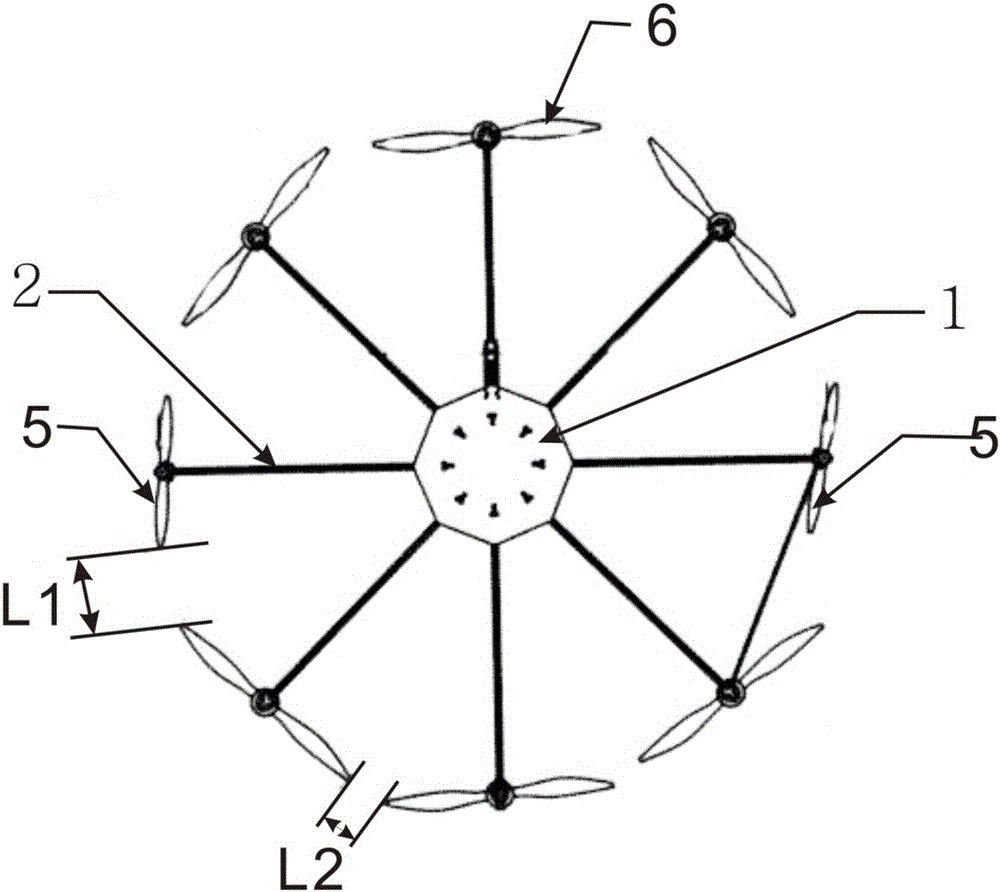

Different-propeller multi-axis aircraft structure and operation method

A multi-axis aircraft and flight controller technology, which is applied to aircraft, unmanned aircraft, aircraft parts, etc., and can solve problems such as turbulence, unfavorable downward penetration, and interference with the direction of nozzle falling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

[0028] The present invention discloses a structure and operation method of a multi-axis aircraft with different propellers. It should be pointed out that the power mechanism described in the following embodiments of the present invention is a brushless motor, and the brushless DC motor is composed of a motor body and a driver. A typical mechatronic product, the KV value of the motor is the no-load speed of the motor, which means that the output voltage increases by 1 volt, and the speed value of the idling speed of the brushless motor increases. From this definition, we can know that the input of the brushless motor voltage and the idling speed of the motor follow a strict linear proportional relationship. The higher the KV value of the motor, the smaller the torque provided, and the KV value is also closely related t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com