Detecting method for pipe welding quality

A detection method and pipe fitting welding technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of inability to detect the welding quality of pipe fittings, and achieve the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

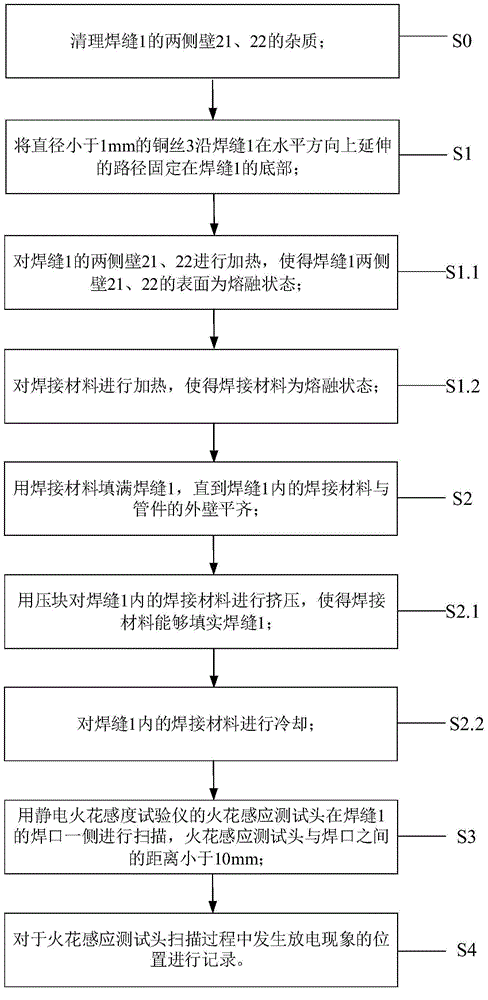

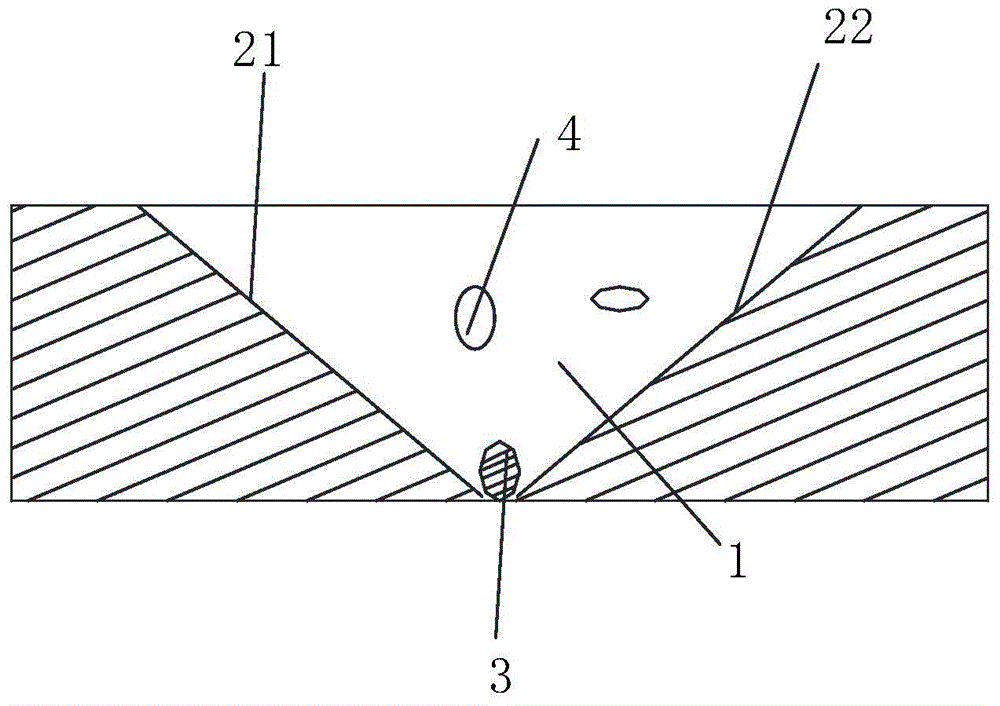

[0032] Please combine Figure 1-2 It should be understood that a method for detecting the welding quality of pipe fittings includes the following steps:

[0033] S0: cleaning the impurities on the two side walls 21 and 22 of the weld 1;

[0034] S1: fixing a copper wire 3 with a diameter of less than 1mm on the bottom of the weld 1 along the path extending horizontally of the weld 1;

[0035] S1.1: heating the two side walls 21, 22 of the weld 1, so that the surfaces of the two side walls 21, 22 of the weld 1 are in a molten state;

[0036] S1.2: Heating the welding material so that the welding material is in a molten state;

[0037] S2: Fill the weld 1 with welding material until the welding material in the weld 1 is flush with the outer wall of the pipe fitting;

[0038] S2.1: Squeeze the welding material in the welding seam 1 with a pressing block, so that the welding material can fill the welding seam 1;

[0039] S2.2: cooling the welding material in the weld 1;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com