A sheet clamping device for laser cutting equipment

A clamping device and laser cutting technology, used in laser welding equipment, welding/cutting auxiliary equipment, auxiliary devices, etc., can solve the problems of inconvenient manual cleaning of waste, troublesome installation and disassembly, and high laser cutting temperature, and achieve convenient cleaning. Recycling waste, easy operation, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

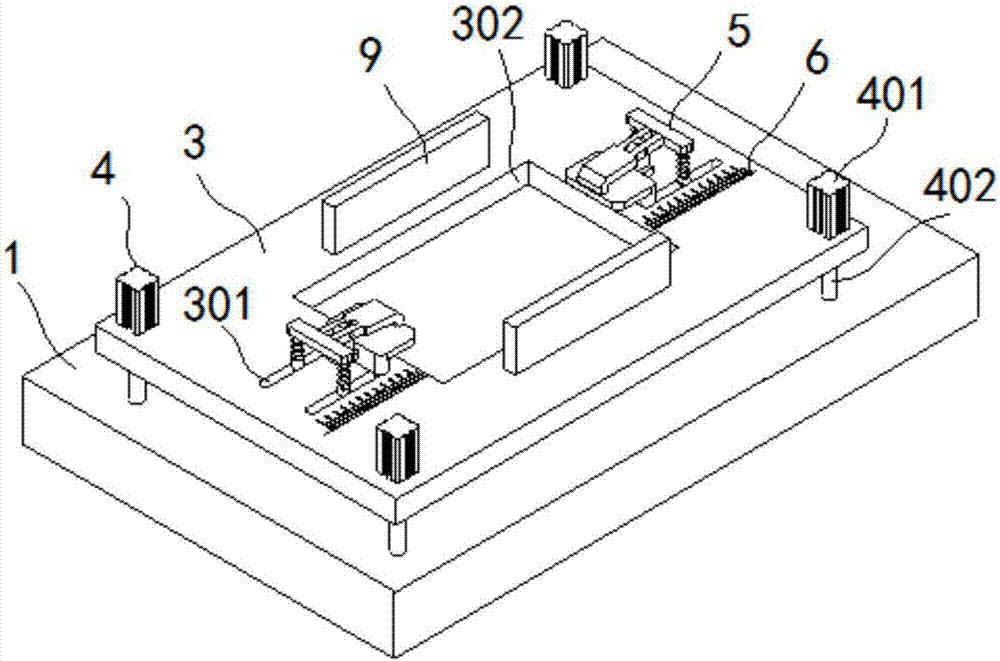

[0027] Such as figure 1 , figure 2 As shown, the sheet material clamping device for laser cutting equipment of the present invention includes:

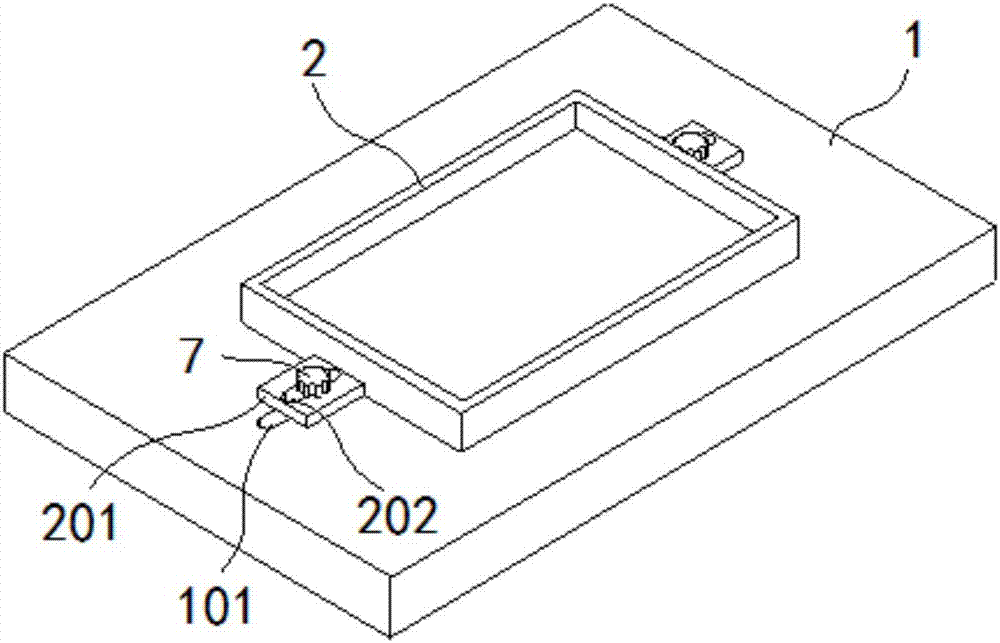

[0028] The bottom plate 1 has a first mounting groove 101 formed on the bottom plate 1.

[0029] Discharge box 2, the discharge box 2 is arranged above the bottom plate 1, the lower end of the side of the discharge box 2 is formed with a mounting plate 201, the mounting plate 201 is formed with a second mounting groove 202, so The second installation groove 202 and the first installation groove 101 are arranged correspondingly.

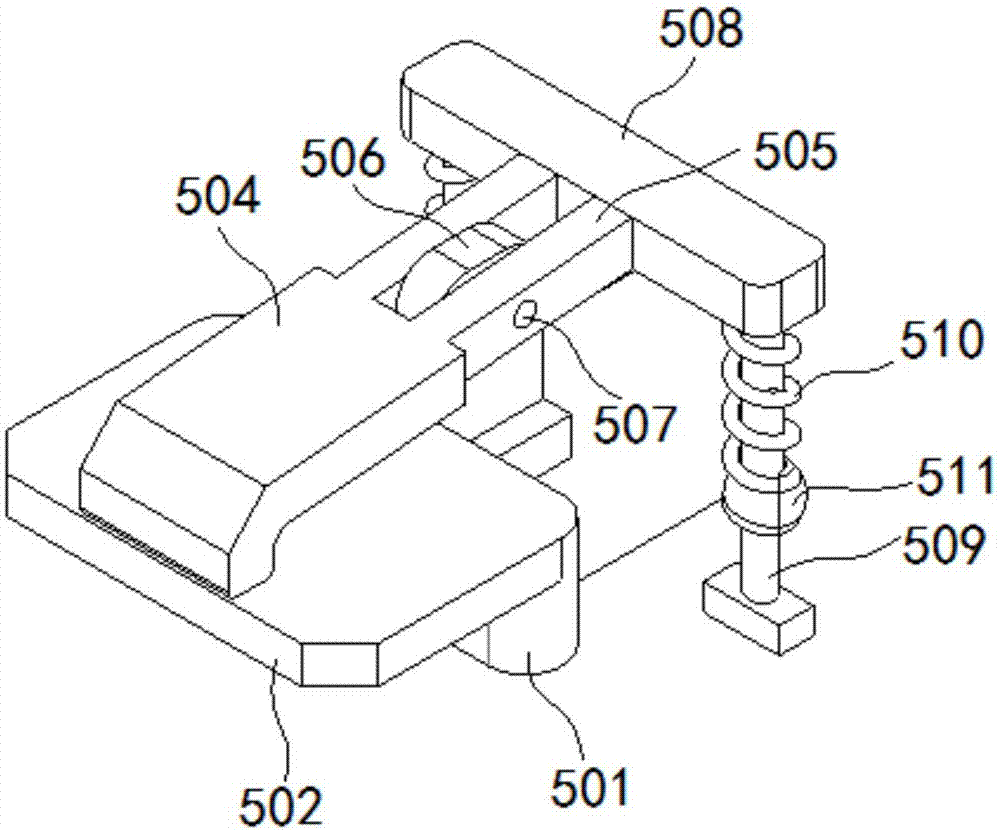

[0030] The processing plate 3 and the lifting cylinder 4 are arranged above the bottom plate 1, the lifting cylinder 4 is provided between the processing plate 3 and the bottom plate 1, and a number of guides are provided on the processing plate 3 槽301. A rectangular processing hole 302 is formed at the center of the processing plate 3, and the length and width of the upper port of the discharge box 2 are larger t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com