Swing Rivet Device

A swinging and riveting technology, which is applied in the field of heavy objects to press down materials, can solve the problems of small riveting impact force, long action vector, riveting failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be described in further detail below by means of specific embodiments:

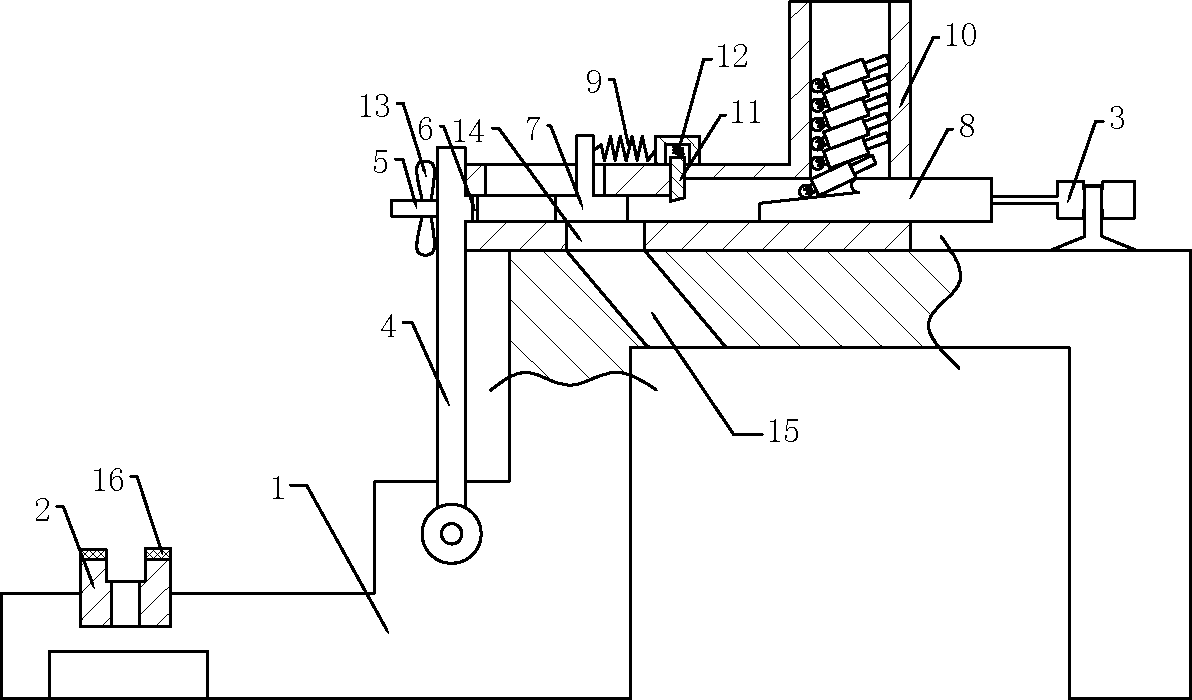

[0018] The reference signs in the drawings of the description include: frame 1, die 2, cylinder 3, rotating rod 4, punch 5, backing plate 6, impact block 7, push block 8, tension spring 9, hopper 10, pressure plate 11 , Compression spring 12, blade 13, feed hole 14, discharge hole 15, buffer rubber pad 16.

[0019] Example basic reference figure 1 Shown: a swing-type rivet device, including a frame 1, a rotating rod 4, a punch 5 and a die 2, the rotating rod 4 is rotatably connected to the frame 1, the punch 5 is rotatably connected to the rotating rod 4, and the punch 5 The blade 13 is welded on the top, the die 2 is fixed on the frame 1, the die 2 is located on the swing track of the punch 5, the die 2 is located below the punch 5, and the upper end of the die 2 is bonded with a buffer rubber pad 16, The frame below the die is connected with a riveting seat by bolts, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com