Package sorting car

A package and rack technology, applied in the field of package sorting vehicles, can solve the problems of prone to misplaced and lost items, low degree of automation, poor operation effect, etc., achieve accurate and reliable sensing effect, high degree of automation, and improve practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

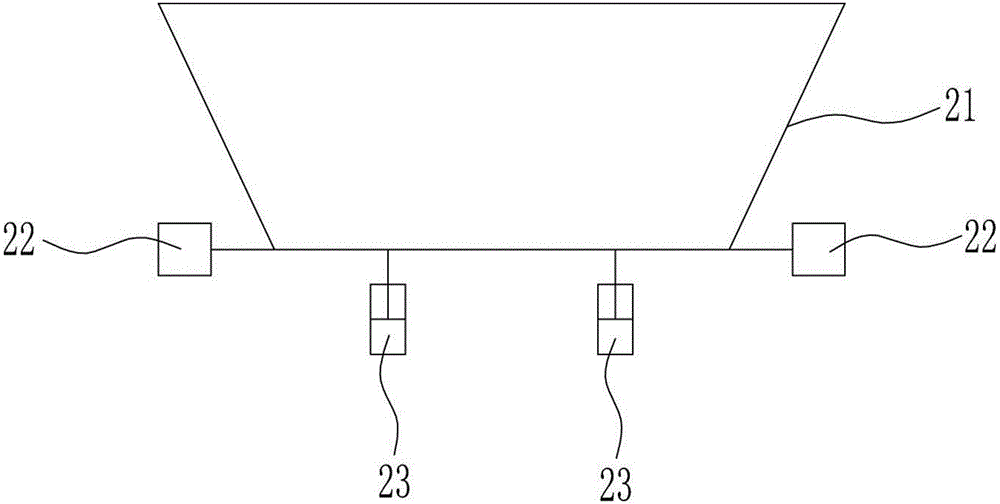

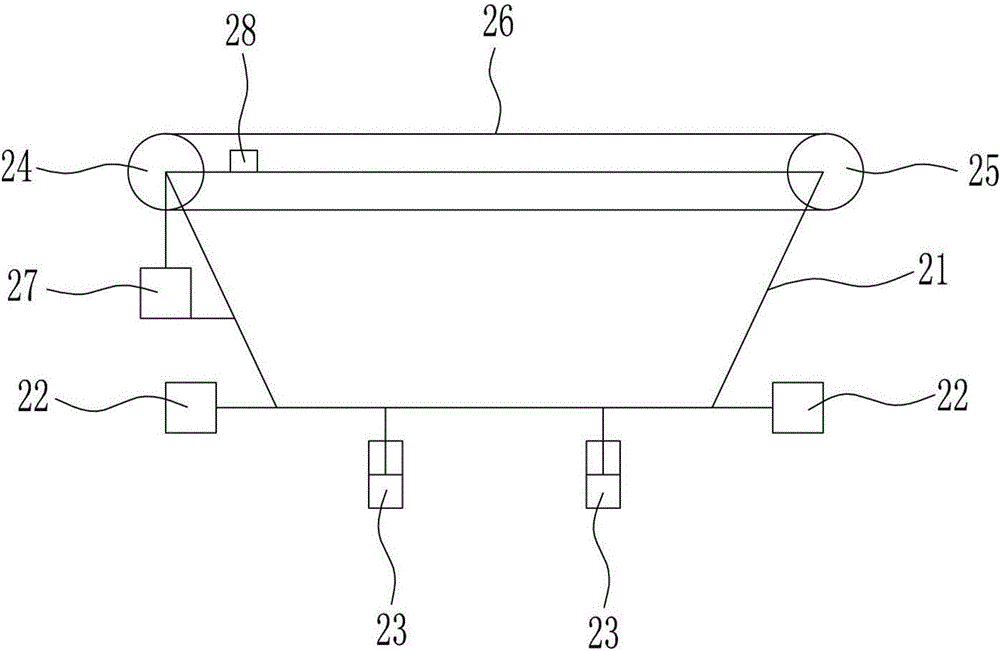

[0033] A parcel sorting vehicle, such as Figure 3-Figure 4 Shown, comprise frame 21, traction device 22 and track wheel 23, traction device 22 is installed on frame 21 both sides, track wheel 23 is installed on frame 21 bottom, is also provided with pulley assembly, motor on frame 21 27 and inductor 28, the pulley assembly includes driving wheel 24, driven wheel 25 and flat belt 26, and driving wheel 24 is installed on one end on frame 21, and driven wheel 25 is installed on the other end on frame 21, and driving wheel 24 and slave The driving wheel 25 is wound with a flat belt 26, the driving wheel 24 is connected with a motor 27, the motor 27 is installed on the frame 21, and one side of the frame 21 is symmetrically provided with an inductor 28 front and back.

Embodiment 2

[0035] A parcel sorting vehicle, such as image 3 and Figure 5Shown, comprise frame 21, traction device 22 and track wheel 23, traction device 22 is installed on frame 21 both sides, track wheel 23 is installed on frame 21 bottom, is also provided with pulley assembly, motor on frame 21 27 and inductor 28, the pulley assembly includes driving wheel 24, driven wheel 25 and flat belt 26, and driving wheel 24 is installed on one end on frame 21, and driven wheel 25 is installed on the other end on frame 21, and driving wheel 24 and slave The driving wheel 25 is wound with a flat belt 26, the driving wheel 24 is connected with a motor 27, the motor 27 is installed on the frame 21, and one side of the frame 21 is symmetrically provided with an inductor 28 front and back.

[0036] The flat belt 26 is symmetrically provided with induction holes 29 , and the inductor 28 is installed directly below the induction holes 29 . It can more accurately sense whether there is a package on t...

Embodiment 3

[0040] A parcel sorting vehicle, such as image 3 , Figure 6 and Figure 7 Shown, comprise frame 21, traction device 22 and track wheel 23, traction device 22 is installed on frame 21 both sides, track wheel 23 is installed on frame 21 bottom, is also provided with pulley assembly, motor on frame 21 27 and inductor 28, the pulley assembly includes driving wheel 24, driven wheel 25 and flat belt 26, and driving wheel 24 is installed on one end on frame 21, and driven wheel 25 is installed on the other end on frame 21, and driving wheel 24 and slave The driving wheel 25 is wound with a flat belt 26, the driving wheel 24 is connected with a motor 27, the motor 27 is installed on the frame 21, and one side of the frame 21 is symmetrically provided with an inductor 28 front and back.

[0041] The motor 27 is a servo motor. The servo motor runs stably, the stroke is precise, the action is sensitive and reliable, and the repeated positioning accuracy is high.

[0042] The sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com