String wind type dust remover

A dust collector and air-type technology, applied in the direction of electrode structure, electrostatic separation, etc., can solve the problem of incapable of efficient capture, and achieve the effect of reducing the cost of corona operation, keeping the dust removal process parameters unchanged, and saving equipment costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

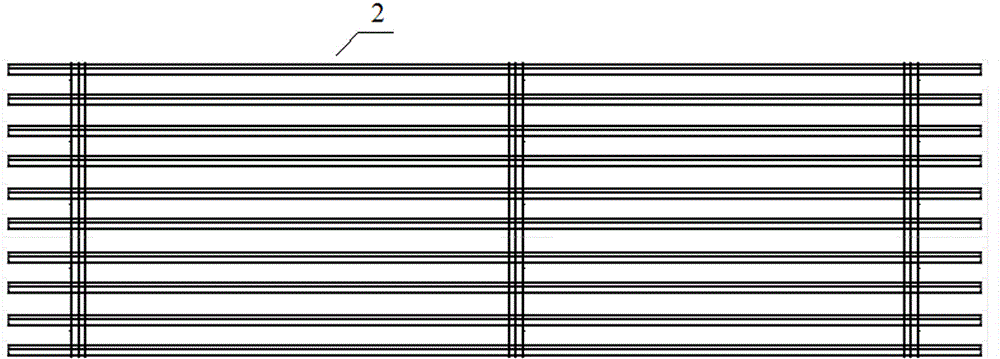

[0021] Figure 1-2 In the embodiment; the slats are combined into a transparent type combined dust collection anode plate (2) according to a certain distance, which is used to replace the old shielded dust collection anode plate.

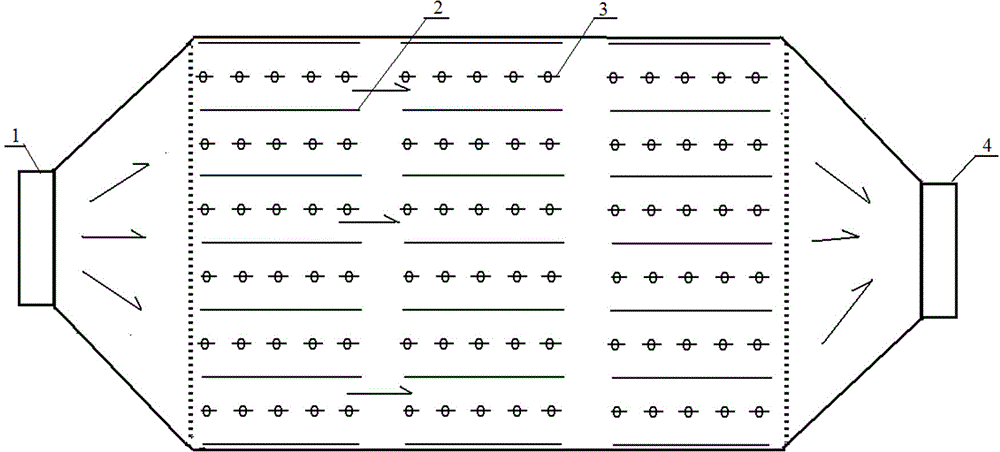

[0022] image 3 In the embodiment; in the old-fashioned three-electric field dust collector box, the airflow passes through each channel in the electric field in a straight line.

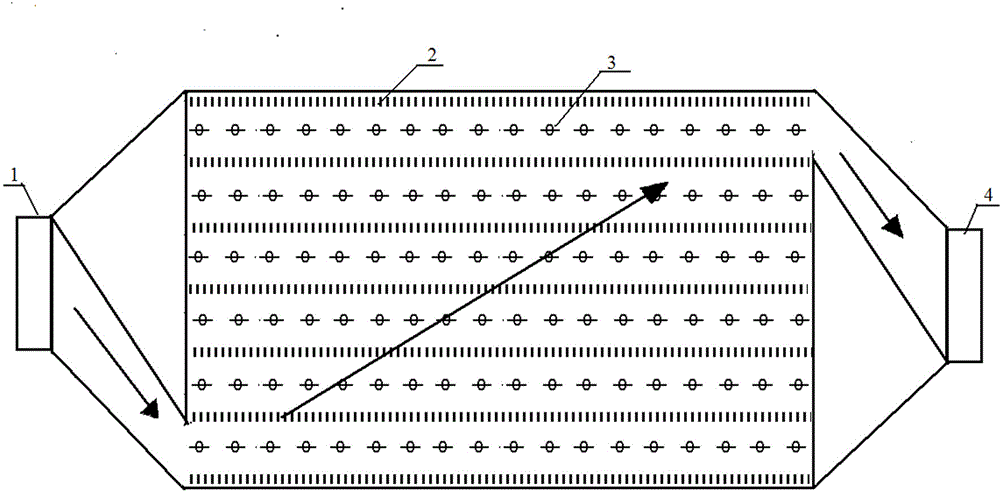

[0023] Figure 4 It is an embodiment of the old-fashioned electrostatic precipitator adopting the new string-wind type electrostatic precipitator technology: the dust-collecting anode plate and the corona burr wire (3) in the old-fashioned electrostatic precipitator with N electric fields are all removed, and then the general The permeable combined dust-collecting anode plate (2) cooperates with the corona prickly wire (3), and in the old-fashioned electrostatic precipitator box, according to a certain distance, they are arranged and combined alternately and longitudina...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com