Powder bottle quantitative suction method and powder bottle quantitative suction device

A suction device and powder bottle technology are applied in the field of a powder bottle quantitative suction method and a powder bottle quantitative suction device, which can solve the problems of frequent suction and frequent weighing, so as to improve the suction efficiency and reduce the number of weighings. , the effect of reducing the number of suction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

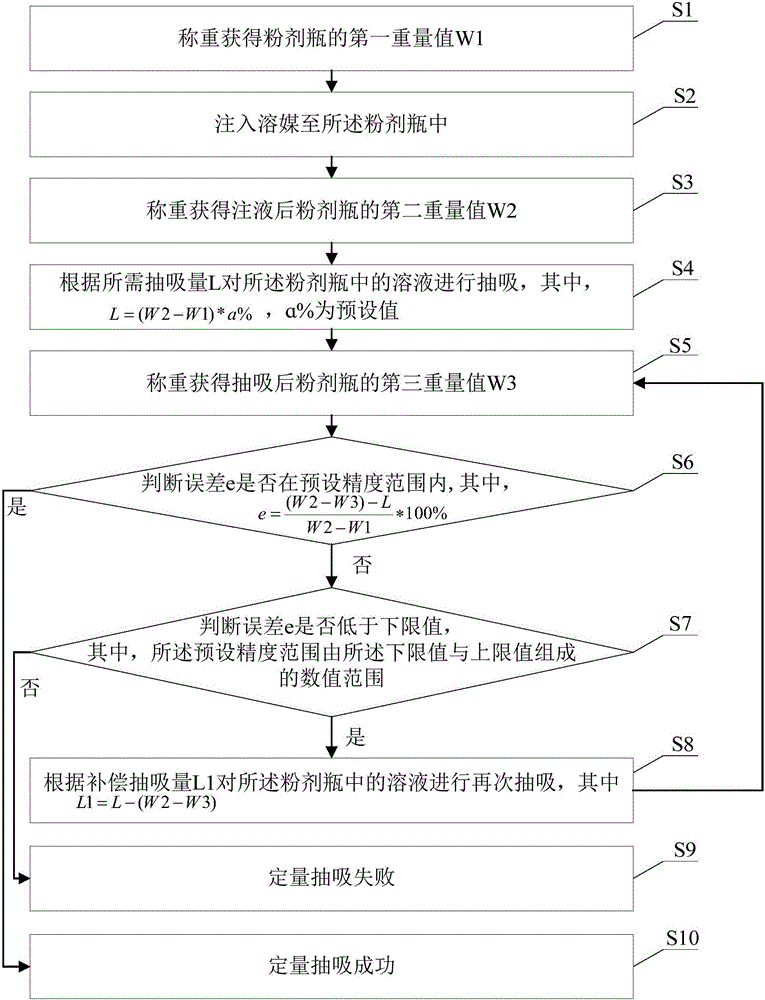

[0049] figure 1 An embodiment of the quantitative suction method of the powder bottle of the present invention is shown. In this example, if figure 1 As shown, the dose bottle quantitative suction method comprises the following steps:

[0050] Step S1, weighing to obtain a first weight value W1 of the powder bottle.

[0051] During the quantitative suction of the powder bottle, first weigh to obtain the weight value of the powder bottle. The first weight value W1 is the weight obtained when the powder bottle is placed on an electronic scale after the bottle cap is removed.

[0052] Step S2, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com