Memory and method of forming the same

A memory and substrate technology, applied in semiconductor devices, electrical solid state devices, electrical components, etc., can solve the problems affecting the production yield of memory, control gate and substrate leakage, etc., and achieve the effect of improving production rate and avoiding leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] After the memory in the prior art is formed, electric leakage between the control gate and the substrate is prone to occur, which will affect the production yield of the memory to a certain extent. The specific reasons are as follows:

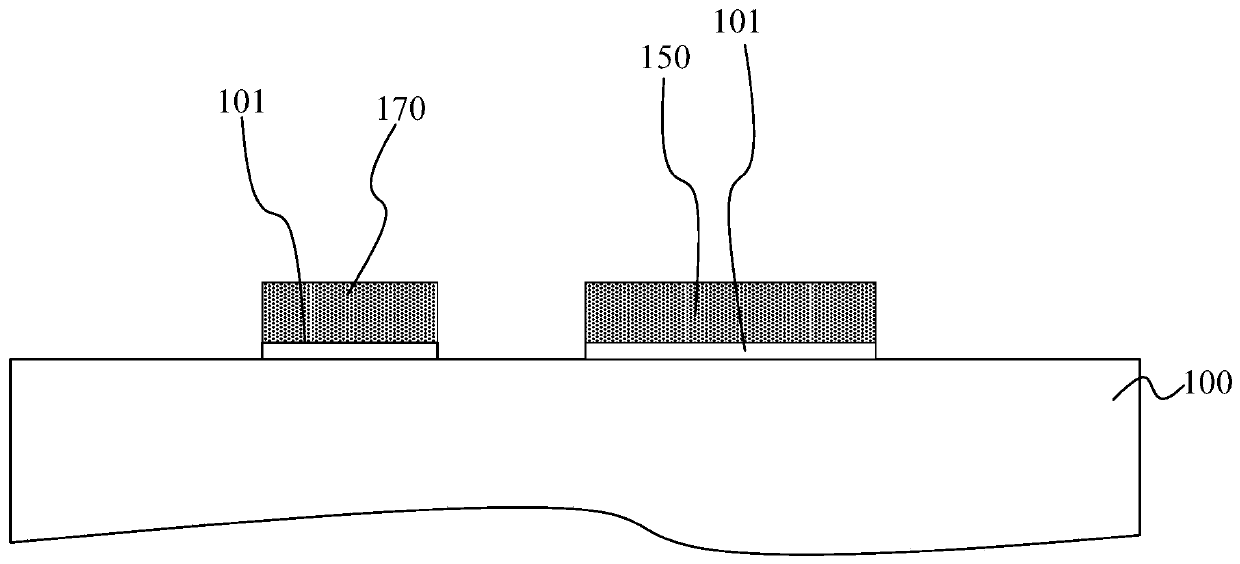

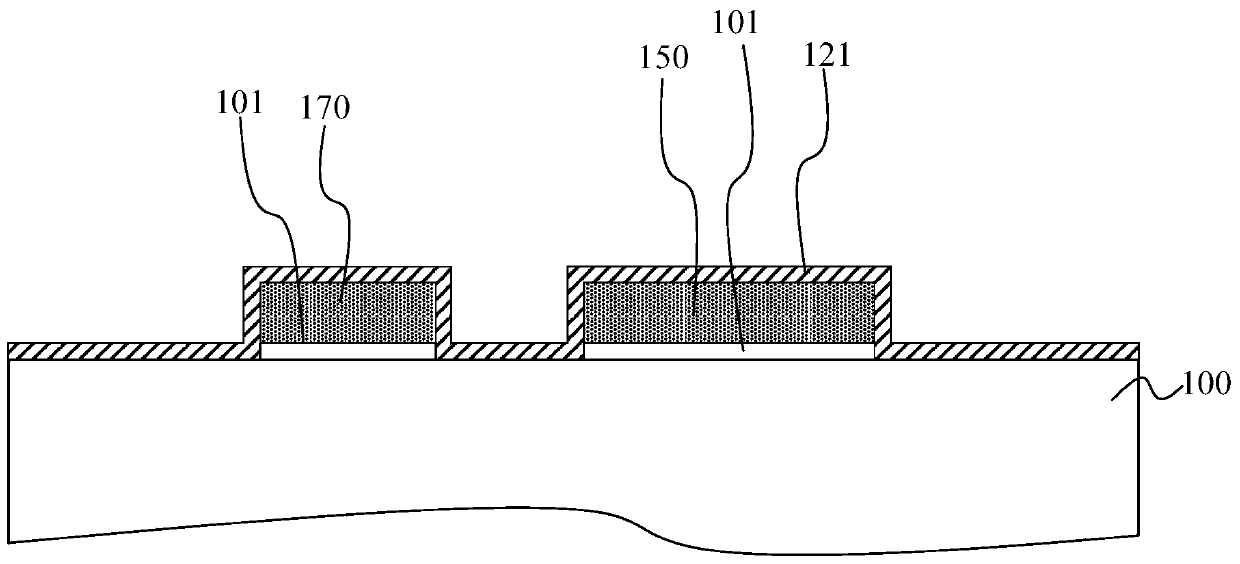

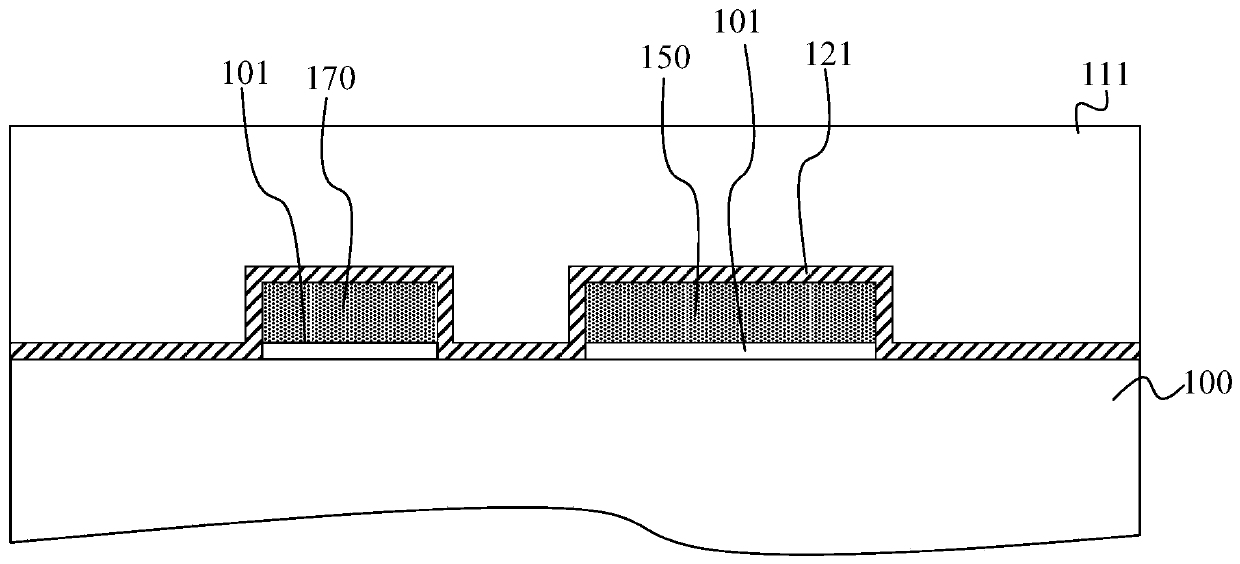

[0045] Taking an electrically erasable programmable read-only memory (EEPROM) as an example, in the process of forming this kind of memory, it is necessary to form a floating gate on the substrate, and then, on the floating gate and the substrate The material layer of the sidewall and the material layer of the control gate are formed at one time. After that, it is necessary to etch the material layer of the control gate to form the control gate, and then etch the exposed material layer of the sidewall to form the sidewall. However, it is difficult to ensure that the sidewalls of the sidewalls formed by etching in the prior art are absolutely flat, and the sidewalls of the sidewalls are easily uneven to form undercuts. The problem of ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com