Wafer bearing mechanism convenient to replace

A wafer and ceramic column technology, applied in the application field of semiconductor thin film deposition, can solve the problems such as difficult replacement, and achieve the effect of convenient disassembly, reasonable structure, safe and reliable disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

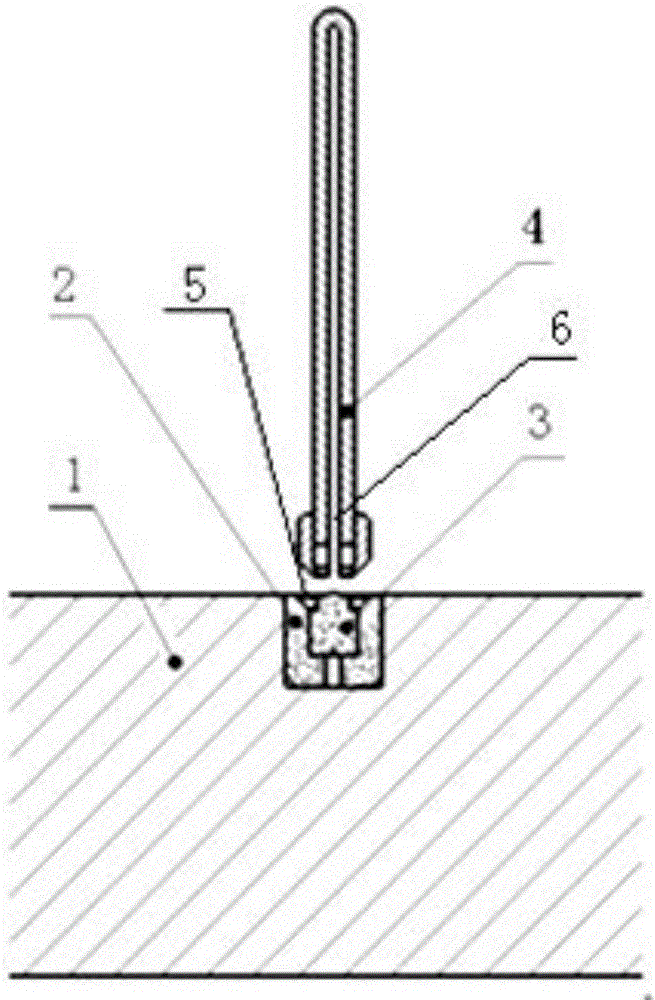

[0012] Refer to attached figure 1 , a wafer support mechanism that is easy to replace, the mechanism includes a hot plate 1, a ceramic sleeve 2, a ceramic column 3 and a special clamp 4. The hot plate 1 is processed with a circular counterbore, and the ceramic sleeve 2 is put into the counterbore, and then the ceramic column 3 is put into the ceramic sleeve 2 . The edge of the inner hole of the ceramic sleeve 2 is provided with a chamfer 5, which can expose the spherical surface of the ceramic column 3, and the spherical surface of the ceramic column 3 is formed with a wedge-shaped groove. When the clamp 4 is in a relaxed state, the opening 6 of the clamp can pass through the ceramic column. The spherical part of 3 is set on the spherical part of the ceramic column 3. When the special clamp 4 is squeezed firmly, the opening of the clamp is smaller than the diameter of the spherical part of the ceramic column, and the ceramic column 3 can be pulled up from the ceramic sleeve 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com